The full name of underfloor heating system is Radiant Floor Heating, which uses the entire floor as a radiator, uniformly heats the entire floor through the heat medium in the floor radiation layer, and conducts heat from bottom to top using the heat storage and upward radiation of the floor itself to achieve the purpose of heating. This technology is both ancient and innovative, dating back to the late Ming Dynasty in China. At that time, it was a heating method only available to the imperial palace and royal family. For example, in the existing Forbidden City, a chimney was built under the blue brick floor, and in winter, smoke was transmitted through the chimney for heating.

Radiant floor heating has gradually evolved from these early beginnings into a practical and widely used system in modern construction. Today, it relies on circulating a heat medium—usually water—through pipes embedded in the floor to provide consistent and comfortable warmth. Central to this system's effective operation are various types of valves, which regulate the flow and temperature of the heating medium to ensure efficiency and safety.

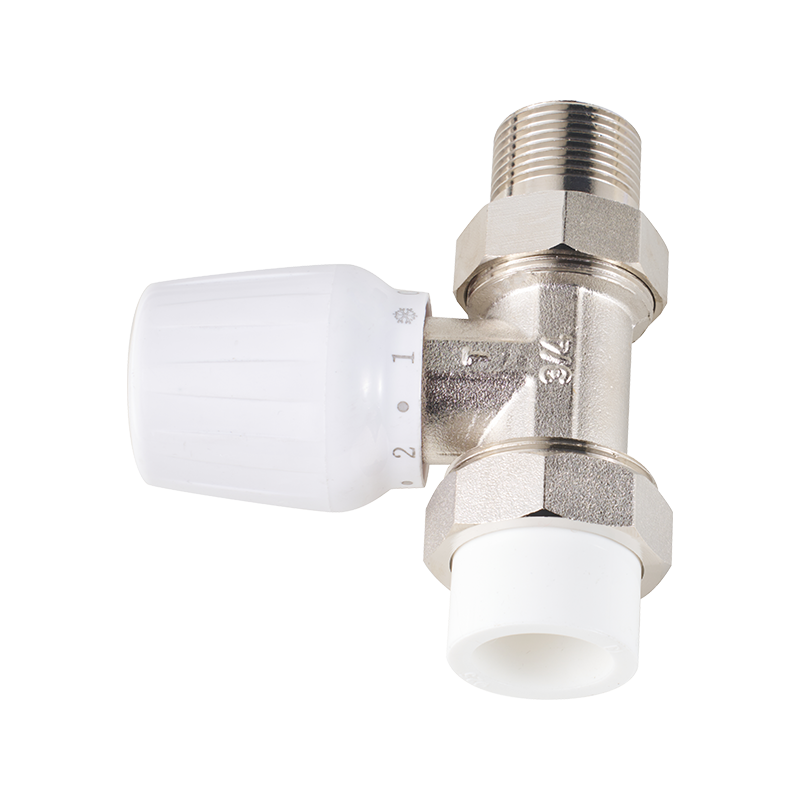

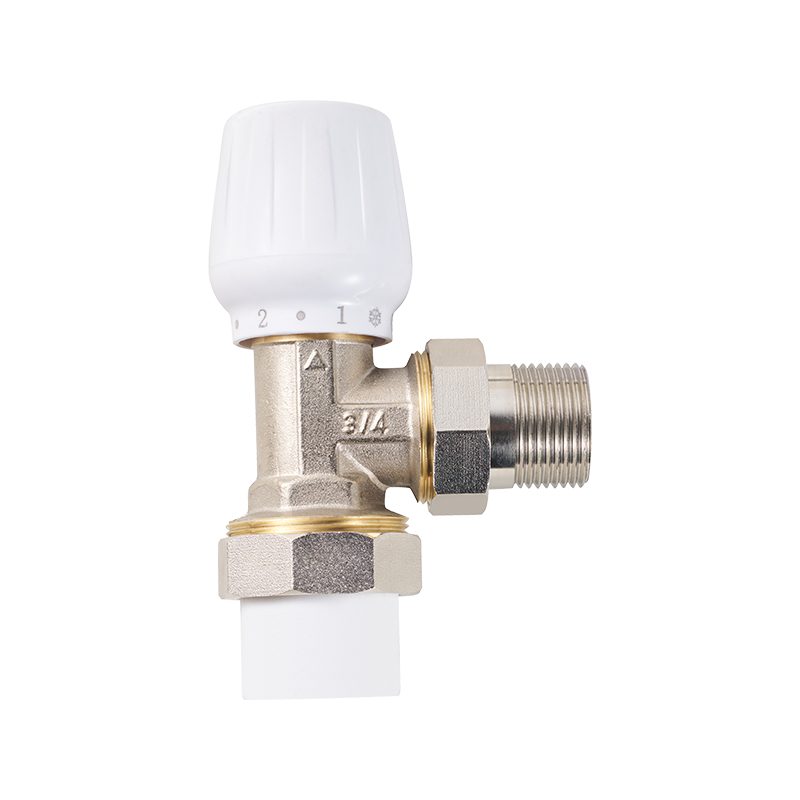

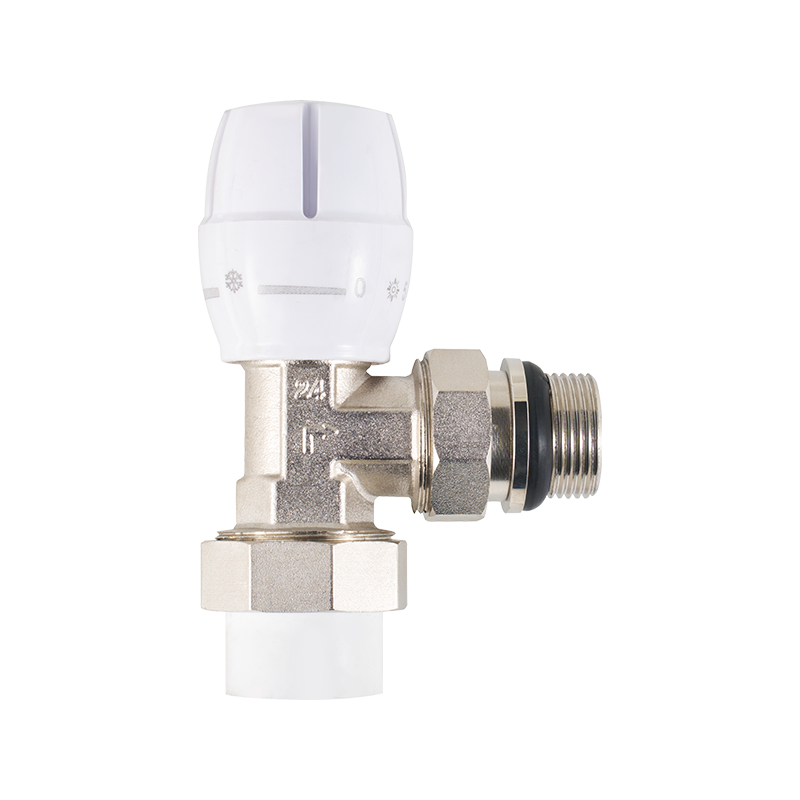

One important component is the floor heating valve. These valves control the flow of hot water into different heating zones, allowing for precise temperature adjustments in each area. By managing the flow rates, the system maintains a balanced distribution of heat, preventing some rooms from becoming too warm while others remain cold. Without these valves, it would be difficult to achieve the even warmth that radiant floor heating promises.

Among the different valves used in these systems, the stop valve and gate valve play significant roles. The stop valve acts as a quick shut-off mechanism, enabling maintenance or emergency isolation of certain sections without disrupting the entire system. Its ability to completely stop the flow of water makes it essential for repairs or adjustments. Meanwhile, the gate valve is designed to regulate the flow more gradually. By raising or lowering a gate inside the valve body, it can control how much water passes through, which is useful for fine-tuning the system’s operation.

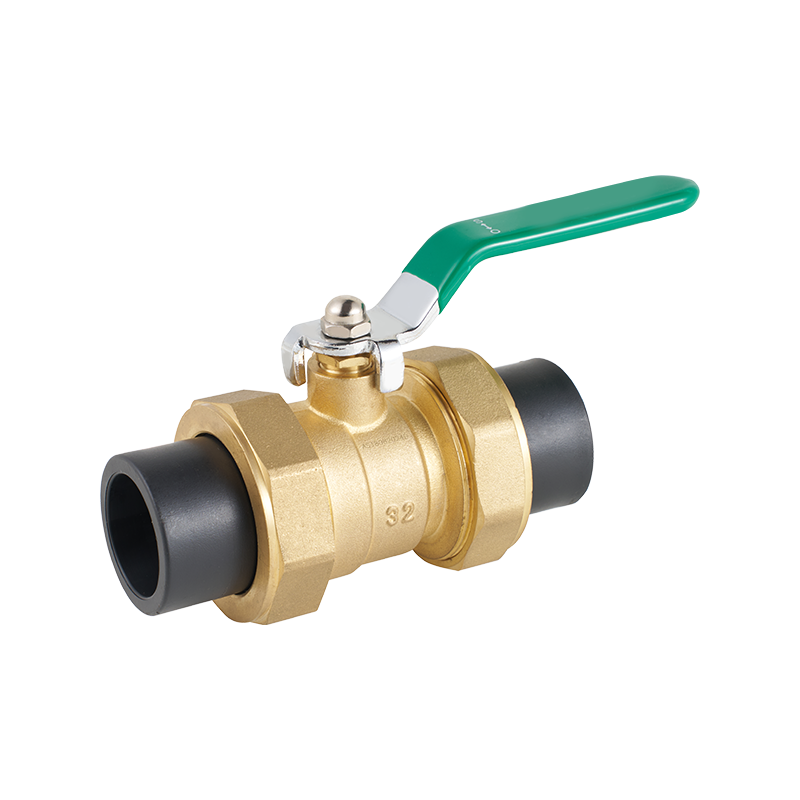

Additionally, the ball valve with long handle is favored in many installations due to its ease of use and reliability. The long handle allows for quick and clear visual confirmation of whether the valve is open or closed. Ball valves are known for their tight sealing capabilities, which reduces the chances of leaks in the system. Their straightforward operation also means that homeowners or technicians can adjust settings without needing special tools, making routine maintenance simpler.

Beyond the valves themselves, the layout of the piping and integration with the manifold system contribute greatly to the overall performance. Manifolds act as distribution hubs, where water flow can be directed precisely through the network of pipes installed beneath the floor surface. The valves attached to these manifolds allow for zone control and balancing, so each area of a building can have individually controlled heating according to need and preference.

The choice of materials for the valves and pipes is also crucial. Since radiant floor heating systems often operate under moderate pressure and temperature, components must be durable and resistant to corrosion or wear. Many valves designed for these systems use brass or stainless steel bodies with internal seals made from materials suitable for hot water environments. This ensures longevity and reduces the likelihood of failures that could cause inconvenience or damage.

From an energy standpoint, efficient valve operation helps reduce waste. Properly balanced valves prevent excessive pumping and uneven heating, which can advance to higher energy consumption. This aspect aligns with modern goals of energy-saving and environmentally friendly building practices, making radiant floor heating an attractive option for many homeowners and builders.

While the concept dates back centuries, the technology around radiant floor heating continues to improve gradually. Innovations in valve design and materials contribute to better control and reliability, making the system easier to install and maintain. This combination of ancient wisdom and modern engineering shows how historic methods can be adapted and refined to meet today’s comfort and efficiency standards.

In conclusion, radiant floor heating is more than just a way to keep floors warm; it is a carefully controlled system where components like floor heating valves, stop valves and gate valves, and ball valves with long handles play critical roles. These parts work together to manage the flow of heat, allowing spaces to be warmed evenly and safely. Understanding their function and importance helps appreciate the complexity behind what might seem like a simple warmth beneath your feet.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US