Certification plays a vital role in the manufacturing and application of pipe system components. In industries where safety, efficiency, and reliability are crucial, ensuring that products meet certain standards is essential. Pipe system components like valves, fittings, and manifolds are often exposed to varying pressures, temperatures, and environmental conditions. Certification provides assurance that these components have undergone rigorous testing and meet regulatory requirements, which in turn helps maintain system integrity and user safety.

One common component in many pipe systems is the boiler water pressure reducing valve. This valve is designed to regulate the pressure of water entering the boiler, ensuring it stays within a safe and manageable range. Without proper certification, there is a risk that the valve could malfunction under high pressure or temperature, potentially pilot to dangerous situations such as leaks, ruptures, or even boiler failure. Certification ensures that such valves conform to specific standards regarding material quality, pressure ratings, and operational reliability. This gives system designers and users confidence that the valve will perform consistently under expected operating conditions.

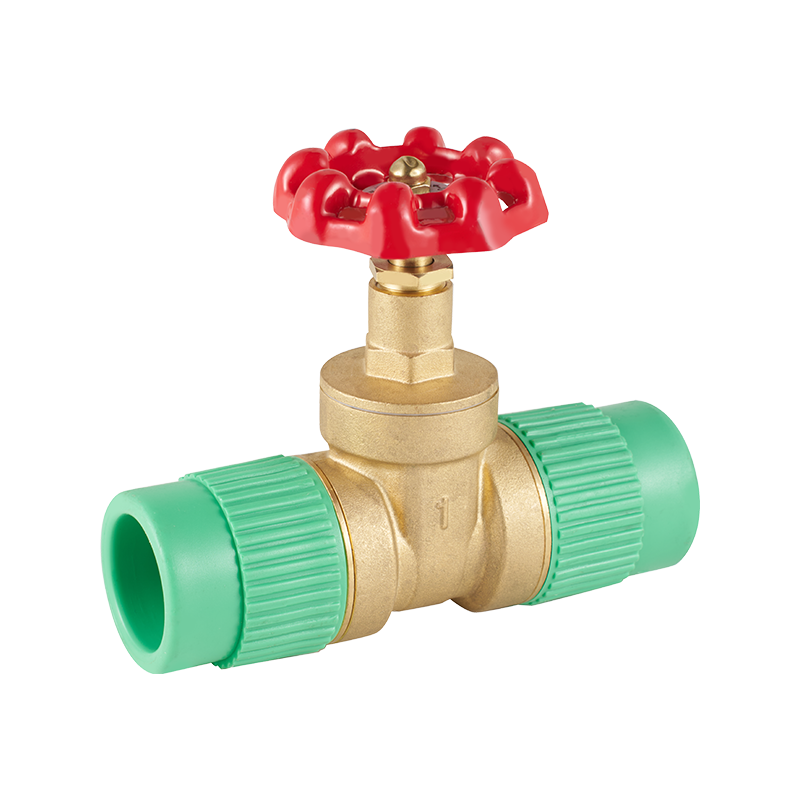

Another component that often requires certification is the kitchen water shut off valve. This valve provides a convenient means of isolating water flow in kitchen plumbing, allowing for maintenance, repairs, or emergency shutoffs. The importance of certification for a kitchen water shut off valve lies in its role in preventing water damage and maintaining hygiene standards. A certified valve has been tested for leak-tightness, durability, and ease of operation, ensuring it can be relied upon when needed. Additionally, certifications may cover materials used to guarantee they are safe for potable water applications and resistant to corrosion or degradation over time.

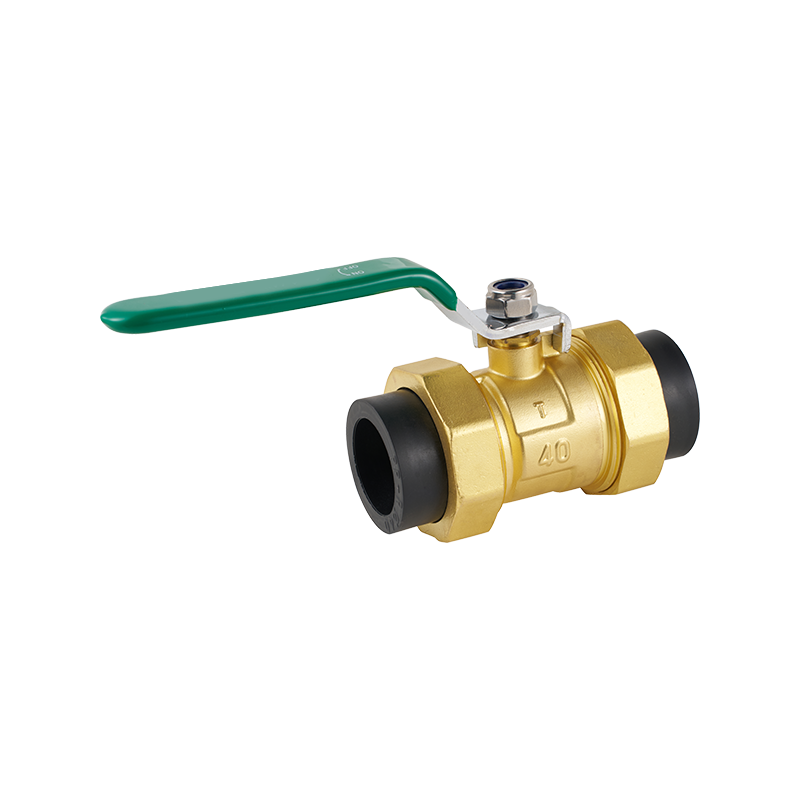

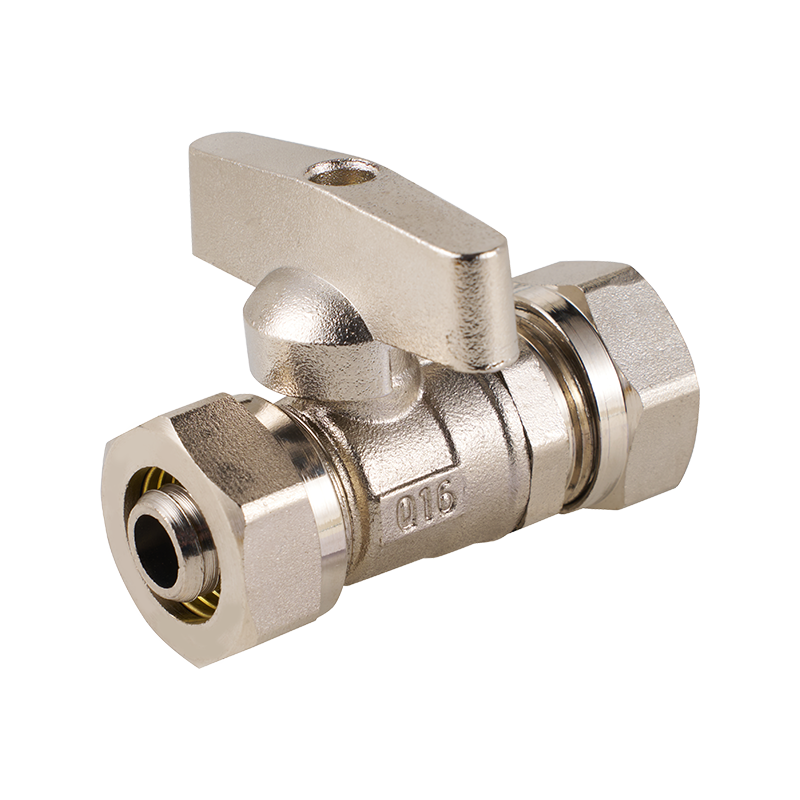

The micro ball valve is a smaller, precise valve used in a variety of applications, including instrumentation, medical devices, and compact piping systems. Despite its size, the micro ball valve must meet strict performance criteria, especially in systems where accurate flow control is necessary. Certification processes verify that these valves can handle pressure fluctuations, resist wear, and maintain tight sealing without leakage. Since micro ball valves are often used in sensitive environments, certifications related to materials and manufacturing processes are also important to ensure compatibility and safety.

Certification is not just about safety; it also affects the overall lifecycle cost and environmental impact of pipe system components. Certified products typically demonstrate better durability and require less frequent replacement, reducing downtime and waste. Moreover, many certification programs emphasize sustainable manufacturing practices and environmentally friendly materials, helping companies meet increasingly strict regulations on emissions and waste.

In addition, certifications provide a common language between manufacturers, installers, inspectors, and end-users. When a pipe system component carries recognized certification marks, it simplifies communication and documentation. For example, during inspections or audits, certified components help demonstrate compliance with local building codes and industry regulations. This can be crucial for obtaining permits or passing safety checks, avoiding costly delays and legal issues.

It is important for companies and consumers to carefully verify the certifications associated with the components they use. Not all certifications are equal, and some might only address limited aspects of a product's performance or safety. Understanding the scope and authority of a certification helps in making informed decisions about product selection. When purchasing valves like boiler water pressure reducing valves, kitchen water shut off valves, or micro ball valves, it is advisable to request certification documentation and confirm that it aligns with relevant industry standards.

In conclusion, certification plays a fundamental role in ensuring that pipe system components perform safely and reliably. Whether it is a boiler water pressure reducing valve that safeguards boiler operation, a kitchen water shut off valve that helps prevent water damage, or a micro ball valve used in precision applications, certification validates that these products meet stringent quality and safety standards. By prioritizing certified components, stakeholders contribute to safer systems, smoother installations, and longer-lasting infrastructure.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US