In modern plumbing systems, valves play a central role in managing water flow, maintaining pressure, and ensuring system safety. From residential buildings to commercial and industrial installations, different types of valves are carefully selected and positioned to meet specific needs. Among these, the ball valve, control valve, and various types of pipe fittings work together to create a functional and reliable water distribution network.

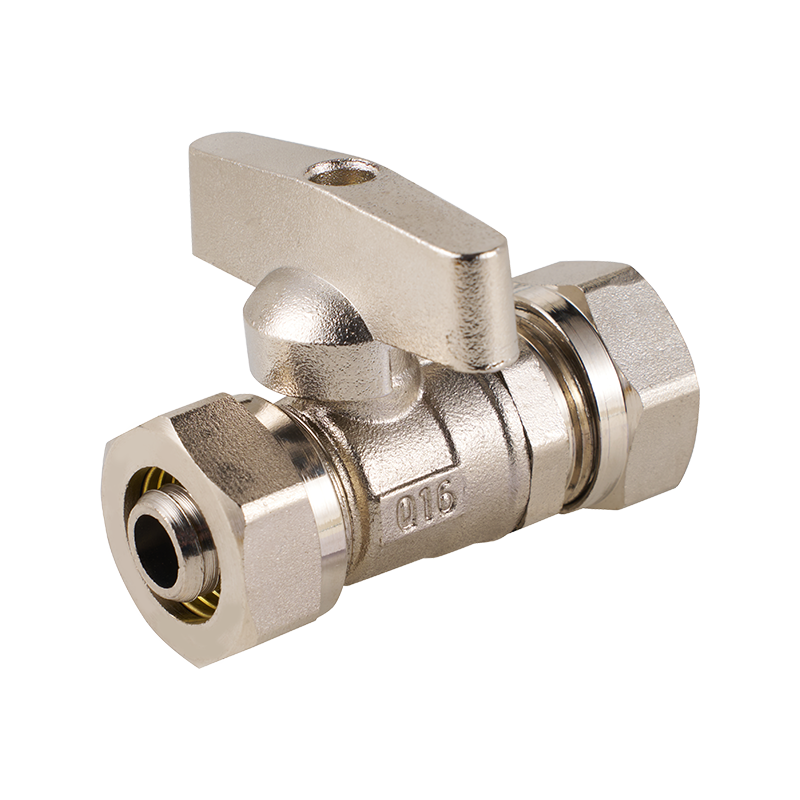

A ball valve pipe fitting is one of the more commonly used components in plumbing due to its simple structure and ease of operation. This type of valve uses a spherical disc to control the flow of fluid. When the valve is open, the hole in the ball aligns with the pipeline, allowing water to flow freely. A quick turn of the handle closes the valve, effectively stopping the flow. Its simplicity makes it ideal for systems that require fast shutoff or straightforward control.

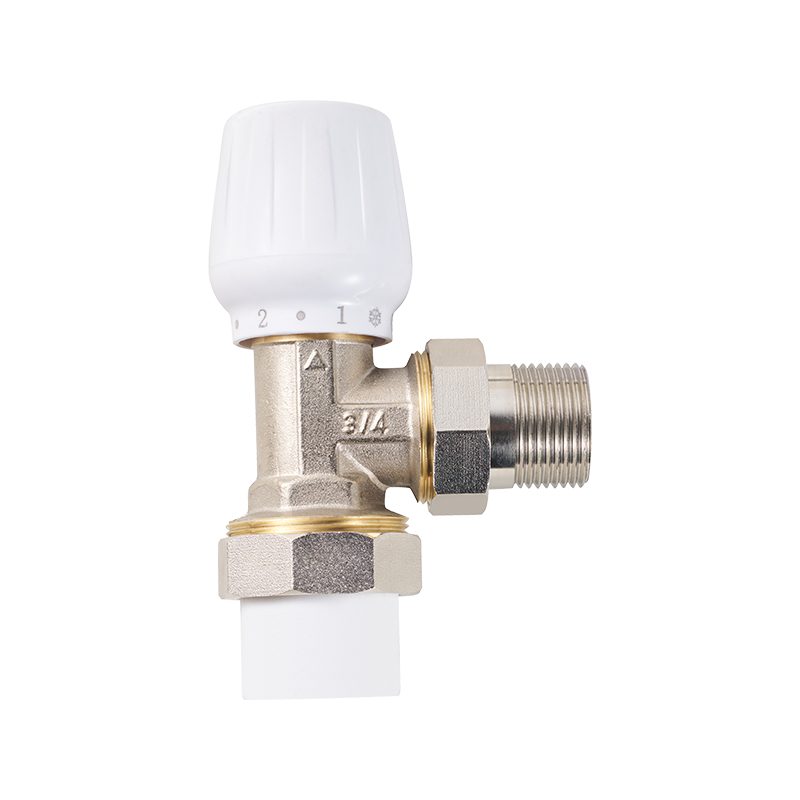

In contrast, the control valve ball valve combination is used in more complex systems where precision is necessary. These valves regulate flow, rather than just stopping or allowing it. In hydronic heating systems, for instance, control valves are often installed to fine-tune the temperature in different zones. By pairing a control valve with a ball valve, installers can allow both manual override and automated adjustment. This combination is especially useful in systems where both efficiency and flexibility are important.

Valves do not work alone in a plumbing setup. They rely heavily on fitting pipe fitting configurations to ensure proper connection and functionality. Pipe fittings are used to connect straight sections of pipe, adapt to different sizes or shapes, and regulate fluid flow. Without them, it would be impossible to incorporate valves into the piping layout effectively. Elbows, tees, reducers, and couplings are just a few examples of fitting types that support valve integration.

When installing a ball valve pipe fitting, it's important to consider the application. For example, in a residential water supply line, a simple on/off mechanism might be sufficient. But in a system where pressure control is needed—such as an underfloor heating network—a control valve ball valve setup provides a more adaptable solution. Additionally, the choice of material—brass, stainless steel, or plastic—affects corrosion resistance, pressure tolerance, and compatibility with the piping material.

The quality and accuracy of fitting pipe fitting placement also impact the performance of valves. Poor alignment or improper sealing can advance to leaks, pressure drops, or even system failure. That's why installers often test and inspect fittings during and after installation to ensure reliability. In systems where temperature and pressure fluctuate, expansion and contraction can also stress the fittings, making material choice and correct installation even more important.

Modern plumbing systems are becoming more sophisticated with the integration of sensors, smart controllers, and energy-efficient components. However, despite these advancements, the core mechanical components—like the ball valve pipe fitting—remain critical. They provide the basic but necessary control that digital systems rely on to function properly.

In industrial applications, valves play an even more vital role. For example, in chemical processing plants or water treatment facilities, control valve ball valve systems help manage the flow of various fluids through complex networks. Here, precision is crucial, and valves must respond quickly and accurately to automated signals. In such cases, fittings must not only connect the parts but also withstand harsh conditions such as high temperatures or corrosive substances.

Ultimately, the effectiveness of any plumbing or fluid transport system depends on how well its components work together. Valves, particularly the ball valve and control valve, serve as key control points within that system. Their integration with fitting pipe fitting elements ensures that water or other fluids flow where, when, and how they should. Whether in a home, an office, or a factory, these components support everyday operations in ways that often go unnoticed—until something goes wrong.

By understanding the roles of valves and how they interact with other plumbing components, system designers and installers can build more reliable and efficient systems. The humble valve may seem like a small piece of the puzzle, but in reality, it plays a big part in keeping things flowing smoothly.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US