Among the many factors that influence valve performance, the method of actuation—manual or automatic—stands out as a key consideration. Each type of valve actuation mechanism has its advantages and limitations, and understanding these can help in selecting the right valve for specific applications. In this article, we will explore the differences between manual and automatic valve actuation, with references to related components such as the nirmal pressure reducing valve, brass inline check valve, and water filter ball valve.

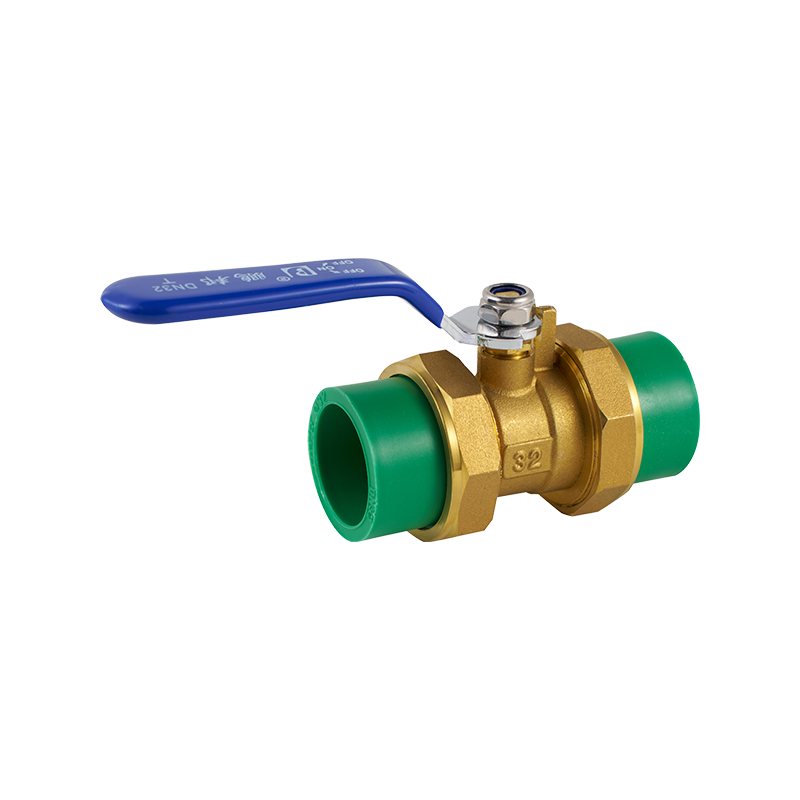

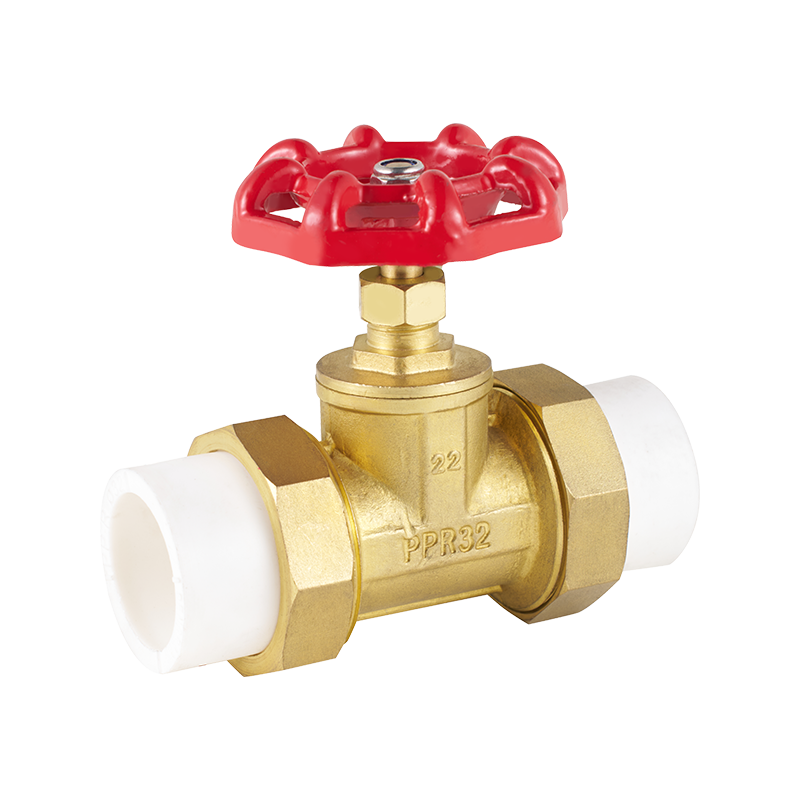

Manual valve actuation requires human intervention to operate the valve. This mechanism typically involves a handwheel, lever, or other manual controls that allow an operator to open, close, or modulate the valve position. Manual valves are straightforward and easy to maintain, making them popular in systems where precise control is not constantly needed. For example, in many plumbing installations, a brass inline check valve or a water filter ball valve is operated manually to control flow and prevent backflow or debris from entering the system.

One common application of manual valves is in pressure management. The nirmal pressure reducing valve, although often available with automatic options, can be manually adjusted in simpler setups. Manual pressure reducing valves allow operators to set the desired downstream pressure by turning an adjustment screw or knob. This flexibility is useful in smaller or less complex systems where automatic control is not necessary or cost-effective.

On the other hand, automatic valve actuation offers remote or self-regulated control of valve position through pneumatic, electric, or hydraulic actuators. These valves adjust in response to system signals or sensor feedback, providing real-time control that enhances system efficiency and safety. For example, automatic actuation is often paired with nirmal pressure reducing valves in systems that require constant pressure regulation without manual adjustment.

Automatic actuation mechanisms are especially valuable in large-scale or complex systems where valves must respond quickly to changing conditions. The brass inline check valve, when combined with automatic actuation, can protect pumps and equipment by automatically preventing backflow without operator intervention. Similarly, water filter ball valves equipped with actuators can be controlled remotely to regulate filtration processes based on system demands.

Despite the convenience of automatic valves, manual valves still have an important role, especially in applications where power sources are limited or where simplicity and cost savings are priorities. For example, a water filter ball valve operated manually can provide reliable on/off control without the need for electrical or pneumatic connections.

When choosing between manual and automatic valve actuation, several factors come into play. The nature of the fluid, system complexity, frequency of valve operation, and maintenance considerations all influence the decision. A nirmal pressure reducing valve with automatic actuation might be ideal for a system requiring frequent pressure adjustments, while a manually operated brass inline check valve could suffice for a basic water supply line.

Maintenance is another important aspect. Manual valves are generally easier to inspect and repair because their components are accessible and straightforward. Automatic valves, with their actuators and control systems, may require more specialized knowledge and tools. For example, troubleshooting an automatic water filter ball valve may involve checking the actuator's electrical connections and control signals, whereas a manual valve simply requires mechanical inspection.

Energy consumption is also a factor to consider. Manual valves require no external power to operate, which can be an advantage in remote locations or emergency situations. Conversely, automatic valves depend on a power source—whether electric, pneumatic, or hydraulic—and thus may incur additional operational costs. In some systems, the energy used by automatic valve actuators can be offset by the efficiency gains they provide through precise control.

In summary, both manual and automatic valve actuation mechanisms have their place in modern piping systems. Manual valves, including the nirmal pressure reducing valve, brass inline check valve, and water filter ball valve, offer simplicity, reliability, and cost-effectiveness. Automatic valves provide enhanced control, responsiveness, and convenience, especially in complex or dynamic environments. Selecting the appropriate actuation mechanism depends on the specific needs of the system, including factors such as maintenance capacity, operation frequency, power availability, and budget.

Ultimately, understanding how each valve type functions and how actuation impacts system performance can help operators and engineers make informed decisions. Whether opting for manual control with a brass inline check valve or integrating automatic actuation into a nirmal pressure reducing valve system, the goal remains to maintain efficient and safe fluid management. The right choice contributes to system longevity, operational stability, and the ability to meet performance requirements under varying conditions.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US