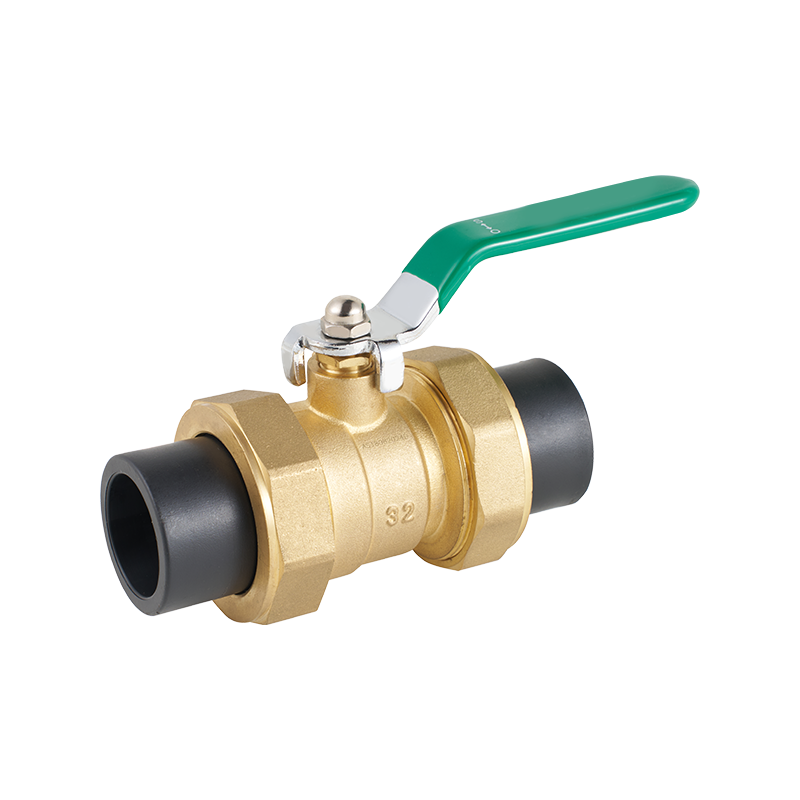

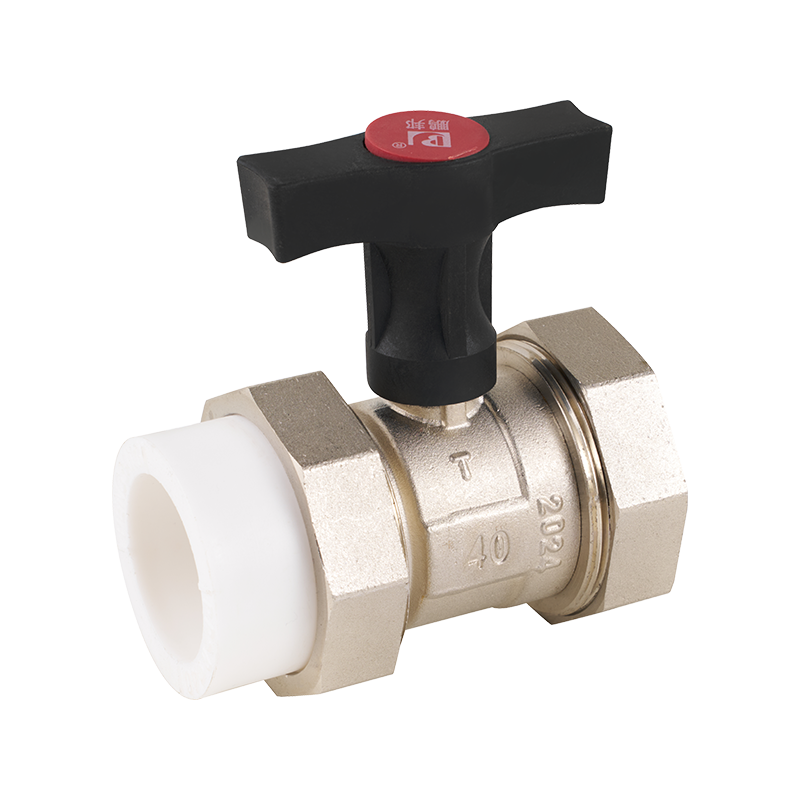

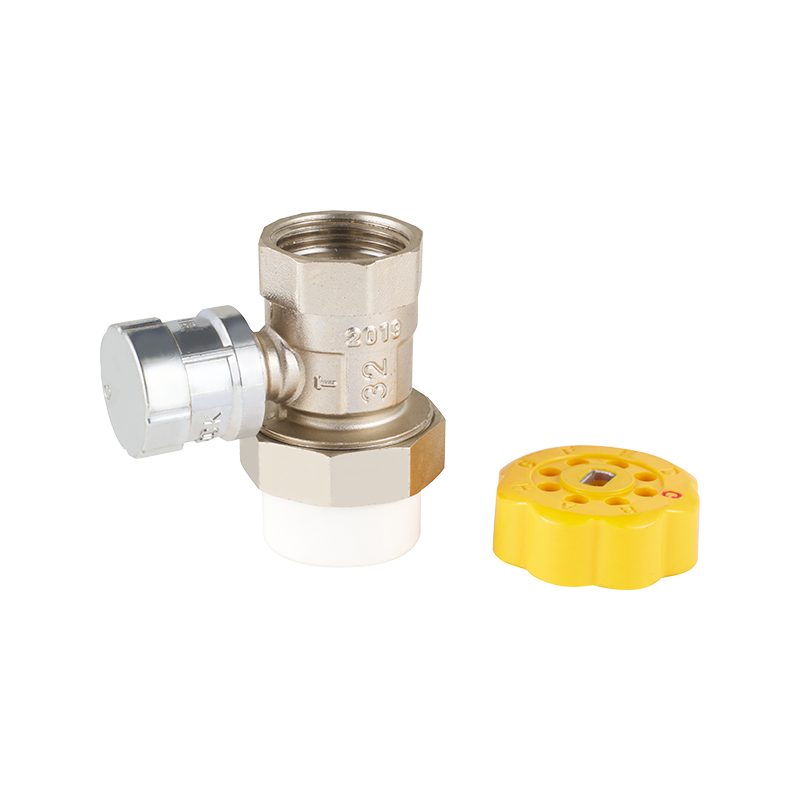

Valves play a crucial role in controlling fluid flow in various systems, and ensuring their longevity requires proper maintenance strategies. Whether you are dealing with a brass pressure reducing valve, a plastic check valve, or a water pressure shut off valve, regular upkeep can help extend their service life and maintain system efficiency.

One of the one steps in maintaining valves such as the brass pressure reducing valve is to perform routine inspections. Over time, valves can develop wear and tear from constant exposure to pressure and varying temperatures. By visually checking for signs of corrosion, leaks, or physical damage, you can catch potential issues early before they escalate. For brass pressure reducing valves, corrosion can particularly impact their ability to regulate pressure accurately, so keeping the valve clean and free from debris is essential.

Similarly, plastic check valves require special attention to ensure their internal components are functioning correctly. These valves prevent backflow in piping systems and must operate smoothly to avoid water contamination or pressure loss. During maintenance, checking for any cracks or material degradation in the plastic is important, as prolonged exposure to chemicals or UV light can weaken the valve body. Flushing the valve to remove sediment buildup also helps in maintaining proper function.

Another important aspect of valve maintenance is lubrication. While not all valves require it, some water pressure shut off valves benefit from periodic lubrication of moving parts to reduce friction and wear. Using a lubricant compatible with the valve materials and the system's fluid can prevent parts from seizing up. This step is particularly helpful in valves that are frequently operated, as it ensures smooth opening and closing actions over time.

Besides physical inspection and lubrication, verifying the correct operation of valves like the brass pressure reducing valve is crucial. Testing how well the valve controls and reduces pressure can identify internal issues such as worn seals or spring fatigue. If the valve is not maintaining consistent pressure, it may need calibration or part replacement to restore proper function. Regular testing prevents unexpected failures in the system and prolongs the valve's effective service period.

For plastic check valves, monitoring for backflow prevention efficiency is key. Any signs that the valve is allowing reverse flow or water hammer effects indicate that the internal mechanisms might be compromised. In such cases, cleaning or replacing components inside the plastic check valve is necessary. Maintaining proper flow direction safeguards the integrity of the entire piping system.

Water pressure shut off valves are often critical in emergency situations to stop water flow quickly. Therefore, testing these valves regularly ensures they operate without delay when needed. Over time, mineral deposits or corrosion may cause the valve to stick or fail. Periodic opening and closing of the valve during maintenance can help prevent this issue by keeping the internal parts moving freely.

Environmental factors also play a role in valve longevity. For example, valves exposed to outdoor conditions, including the brass pressure reducing valve or water pressure shut off valve, should be protected from bad weather and debris. Installing protective covers or enclosures can reduce the risk of damage caused by freezing temperatures or dirt ingress. Keeping valves in a clean environment reduces wear and helps maintain performance.

Proper installation is another foundational element that impacts valve maintenance. Incorrectly installed valves, regardless of type, are more prone to leaks, mechanical stress, and premature failure. Ensuring that the brass pressure reducing valve, plastic check valve, and water pressure shut off valve are fitted according to manufacturer recommendations sets the stage for longer service life and easier maintenance.

When it comes to replacement parts, using components designed specifically for your valve model is important. Substituting parts can advance to poor fit, compromised sealing, and eventual breakdown. Whether replacing seals in a brass pressure reducing valve or internal components of a plastic check valve, matching the original specifications helps maintain the valve's integrity.

Record keeping also supports effective valve maintenance. Keeping track of inspection dates, repairs, and replacements for valves such as the water pressure shut off valve allows for timely interventions before failures occur. A maintenance log can also help identify recurring problems that might need design changes or system upgrades.

In summary, extending the service life of valves like the brass pressure reducing valve, plastic check valve, and water pressure shut off valve requires a combination of regular inspection, cleaning, lubrication, testing, and proper installation. Attention to environmental protection and timely replacement of worn parts further contributes to valve durability. By following these maintenance strategies, the valves can continue to perform their functions reliably and support the overall efficiency of fluid control systems.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US