Underfloor heating systems have become an increasingly preferred method of indoor climate control, especially in modern residential and commercial buildings. At the heart of these systems lies a network of components that work together to ensure safe, efficient, and balanced heat distribution. Among these components, valves play a crucial role. Whether it's controlling water flow, balancing temperatures across zones, or filtering debris to maintain cleanliness in the system, the right valves ensure smooth operation over the long term.

One of the lots of widely used valves in underfloor heating installations is the water level shut off valve. This valve acts as a safety device that prevents overflow or damage caused by excessive water in the circuit. When the water level reaches a certain point, this valve automatically closes off the supply, protecting both the piping network and connected devices from unnecessary pressure and potential leaks. In underfloor heating, where pipes are often embedded beneath concrete or other flooring materials, preventing water damage is not only a matter of efficiency but also of preserving the building's structural integrity.

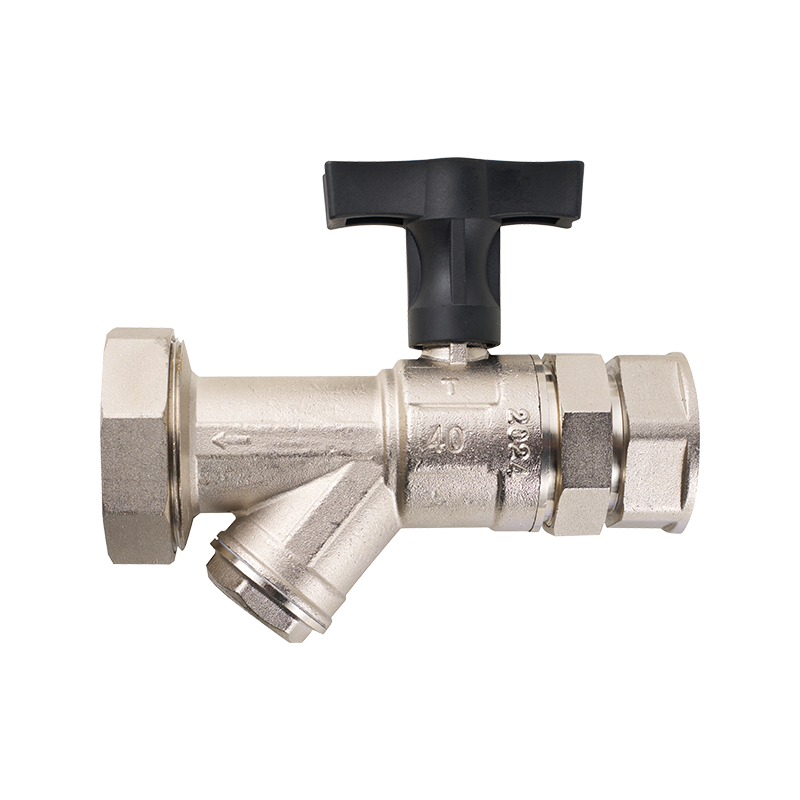

Another essential component is the valve and filter combination. These are often integrated together to streamline the control and protection of the water flow. The filter element captures dirt, rust particles, and other debris from the system's water supply. Over time, these particles can accumulate and clog small passages within the manifold or pipes, reducing efficiency and increasing wear. The inclusion of a valve alongside the filter allows the flow to be stopped quickly when the filter needs cleaning or replacement, without having to shut down the entire system. This pairing is particularly useful in regions where water quality can vary and cause scaling or contamination within heating circuits.

Speaking of system layout, lots of underfloor heating setups are divided into multiple zones or circuits. Each of these zones requires accurate water flow control to ensure that the temperature in every room or section is balanced. This is where the center manifold comes into play. The center manifold is a key distribution point for hot water that splits it into several branches, each piped to a different zone. Integrated with various valves, including flow meters and balancing valves, the center manifold ensures that each zone gets the right amount of hot water depending on its specific heating requirement. Without this control, some zones might be too warm while others remain underheated.

Within the manifold, several valve types are typically installed. Therlots ofatic valves are used to automatically adjust the flow based on temperature feedback from room sensors. Manual balancing valves are employed to fine-tune each circuit by adjusting flow rates to match the hydraulic resistance of the piping. Some systems also incorporate actuator valves, which can open or close circuits remotely through a therlots ofat or central control panel.

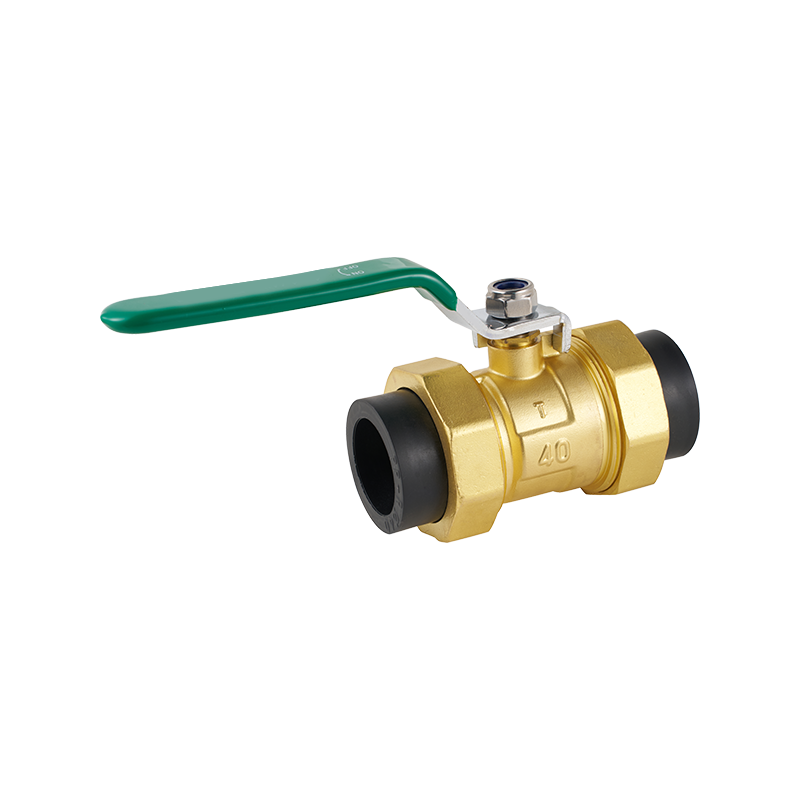

An important consideration in valve selection is material compatibility. Brass and stainless steel valves are commonly chosen due to their resistance to corrosion and thermal expansion. For plastic piping systems, such as those made from PEX or PP-R, the valves must be designed to handle similar expansion behavior and connect seamlessly without leaks. When selecting a valve, installers must also consider pressure ratings and compatibility with glycol-based heating fluids, which are sometimes used in underfloor systems for freeze protection.

In recent years, valve design has advanced to include more compact formats that fit easily into tight installation spaces, such as in-wall or under-cabinet manifolds. These newer valves often come with quick-connect fittings, visual indicators for open/closed status, and easier maintenance access.

In summary, valves are a silent but critical element of any underfloor heating system. From safety-focused devices like the water level shut off valve, to multi-functional components such as the valve and filter unit, and the distribution role played by the center manifold, each type contributes to the system's overall performance and reliability. Choosing the right combination of these valves, with proper installation and maintenance, helps ensure comfortable, consistent, and efficient heating throughout the space.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US