This article explores some of the key design features of modern water distribution manifolds, with a focus on applications such as hydronic floor heating systems and industrial fluid control.

One of the foundational elements in manifold design is the ability to handle different types of valves that control flow and pressure. For example, a high pressure butterfly valve is often integrated into manifolds intended for systems requiring precise regulation under varying pressure conditions. Butterfly valves are known for their compact design and quick operation, which make them suitable for applications where space is limited but reliable flow control is necessary. The high pressure variants are constructed to withstand demanding environments, maintaining tight shutoff and preventing leaks, which are critical in water distribution networks.

In hydronic heating systems, manifolds serve as the central hub for distributing heated water to various zones or rooms. The hydronic floor heating manifold is specifically designed to accommodate multiple circuits, allowing precise temperature control and balanced flow rates across the floor heating loops. These manifolds typically include features such as integrated flow meters and balancing valves that help installers fine-tune the system for consistent heat output. The layout and material choice for these manifolds emphasize corrosion resistance and thermal stability, which contribute to the longevity and reliability of the heating system.

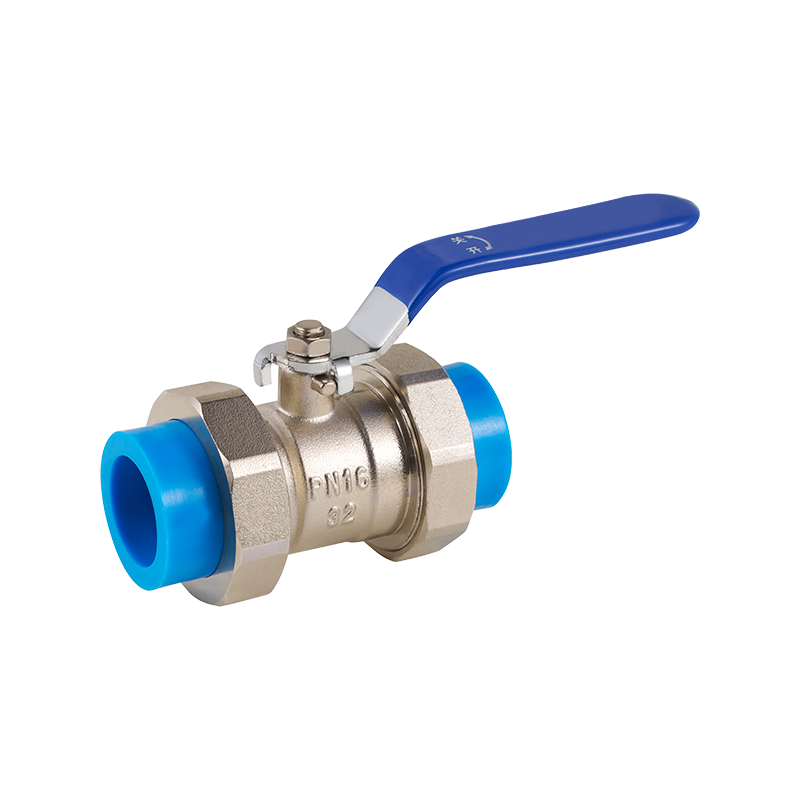

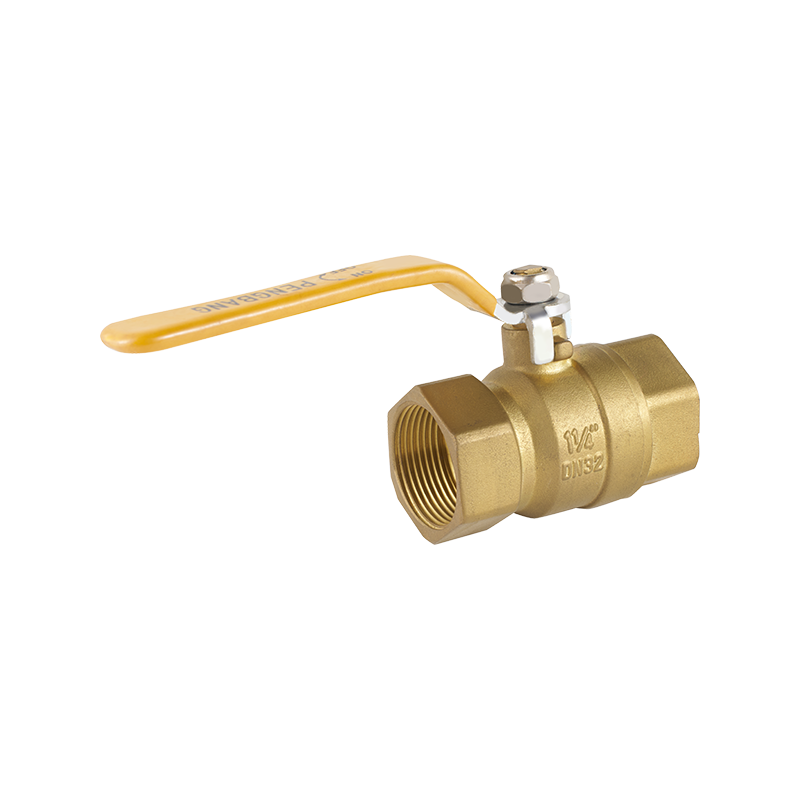

Modern water distribution manifolds also address safety and operational efficiency by integrating components like the full port gas valve. While primarily associated with gas systems, full port valves can also be used in manifold designs where full bore flow is necessary. The advantage of a full port valve lies in its ability to offer small flow resistance, allowing the fluid to pass through without restriction when fully open. This feature reduces pressure loss across the valve, which can be particularly important in large-scale systems or applications where flow efficiency directly impacts performance and energy consumption.

Material selection is another crucial design consideration for modern manifolds. Stainless steel and high-grade brass remain common choices because of their resistance to corrosion and ability to endure temperature fluctuations. For hydronic systems, materials must withstand both the heated water temperature and any chemicals used in the water treatment process. Additionally, some manifolds are designed with protective coatings or surface treatments that extend their service life by preventing mineral buildup and oxidation.

Ease of installation and maintenance is also a priority in contemporary manifold design. Many manifolds are manufactured with modular components, allowing for customization according to specific project requirements. Modular designs simplify both initial installation and future maintenance by enabling quick replacement of parts or easy addition of extra circuits. Additionally, standardized connection interfaces ensure compatibility with various pipe sizes and valve types, reducing installation errors and time.

Another feature that has gained attention is the integration of smart control systems with water distribution manifolds. Sensors and automated valves can now be installed alongside traditional components, allowing for real-time monitoring of flow rates, temperatures, and pressure levels. This integration enables more precise control and energy savings, especially in hydronic floor heating systems where zone-specific adjustments enhance comfort and efficiency.

The physical layout of manifolds is optimized to reduce pressure drops and turbulence in the fluid flow. Smooth internal passageways and full port valve designs contribute to maintaining steady flow rates, reducing wear on system components. Proper spacing of outlets and ergonomic arrangement also facilitate the attachment of pipes and valves, ensuring that the manifold fits neatly within mechanical rooms or utility spaces.

Safety mechanisms, such as pressure relief valves and shut-off features, are incorporated into many manifold designs. These components help protect the system from pressure surges or leaks, lessening the risk of damage or water loss. The use of reliable sealing materials and robust valve designs ensures that the manifold maintains system integrity over long periods of use.

In conclusion, modern water distribution manifolds combine thoughtful design elements to provide durability, efficiency, and ease of use across various applications. From the integration of high pressure butterfly valves to specialized hydronic floor heating manifolds and the inclusion of full port gas valves, these components work together to create systems that meet the practical demands of today's plumbing and heating projects. Attention to materials, modularity, and smart integration continues to shape manifold design, offering solutions that support both installer convenience and end-user comfort.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US