Hydronic heating systems rely on a carefully balanced flow of heated water to provide consistent warmth throughout a building. A key component that ensures this balance is the manifold, which acts as a central distribution hub for the heating fluid. Among the various materials available, stainless steel has become a preferred choice for manifolds in hydronic systems due to its durability, resistance to corrosion, and ability to withstand a wide range of temperatures and pressures.

One of the important factors that make stainless steel manifolds suitable for hydronic heating is their inherent resistance to rust and scaling. Unlike some metals, stainless steel maintains its structural integrity even in the presence of moisture, which is a constant in heating circuits. This property not only extends the service life of the manifold but also helps maintain water quality, preventing contamination that can occur when corrosion products enter the system.

In hydronic heating setups, particularly infloor heating systems, the manifold plays a critical role. The infloor heating systems manifold is designed to distribute heated water evenly to various zones or loops embedded beneath floors. This distribution allows for more precise temperature control in different rooms or areas, enhancing comfort and energy efficiency. Stainless steel manifolds, with their strength and corrosion resistance, support these systems well, ensuring reliable performance over time.

When designing or maintaining hydronic heating systems, the choice of valves integrated with the manifold is also essential. For instance, the use of a 20 inch butterfly valve can be found in larger scale heating applications. Butterfly valves are valued for their relatively simple design and ability to provide tight shutoff with low pressure drops. A 20 inch size valve is typically utilized in commercial or industrial heating setups where larger flow capacities are necessary. This valve helps regulate the flow of water entering or leaving the manifold, contributing to overall system stability.

Another valve type that often pairs with stainless steel manifolds is the 4 way gas valve. Although primarily associated with gas flow control, in some hydronic systems that incorporate gas-fired boilers or gas heat exchangers, these valves regulate the supply and distribution of gas. A 4 way gas valve can direct the flow between different circuit paths, allowing for flexible operation of heating zones or maintenance bypasses. Its role is particularly important in systems where fuel efficiency and safety are priorities, and its integration with the manifold system can influence overall heating performance.

Installation and maintenance of stainless steel manifolds require attention to detail to ensure good operation. Proper sealing and fitting are necessary to avoid leaks, which can be detrimental to the system's efficiency and longevity. Additionally, manifolds need to be designed with accessibility in mind since balancing, flushing, or servicing different heating loops often involves adjusting valves or cleaning components. Stainless steel's smooth surface also aids in preventing sediment buildup, which can obstruct flow or degrade system performance.

In the context of infloor heating, the manifold must handle varying flow rates as different zones demand different heating levels. Stainless steel manifolds typically include multiple ports for connecting supply and return pipes, along with valves for individual loop control. These valves allow installers or homeowners to adjust flow rates and temperatures according to the specific needs of each area, improving comfort and reducing unnecessary energy use.

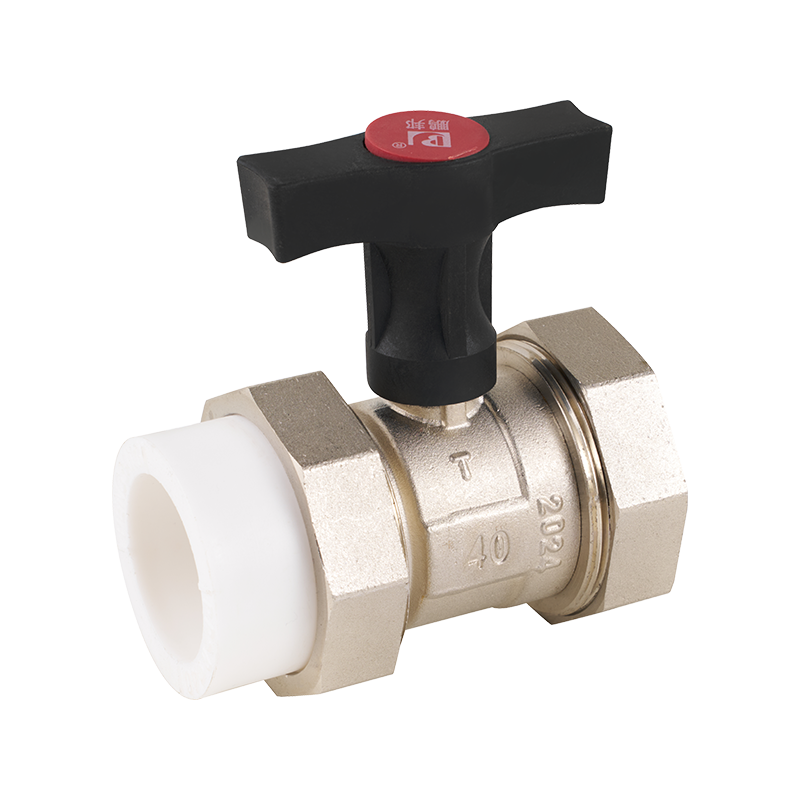

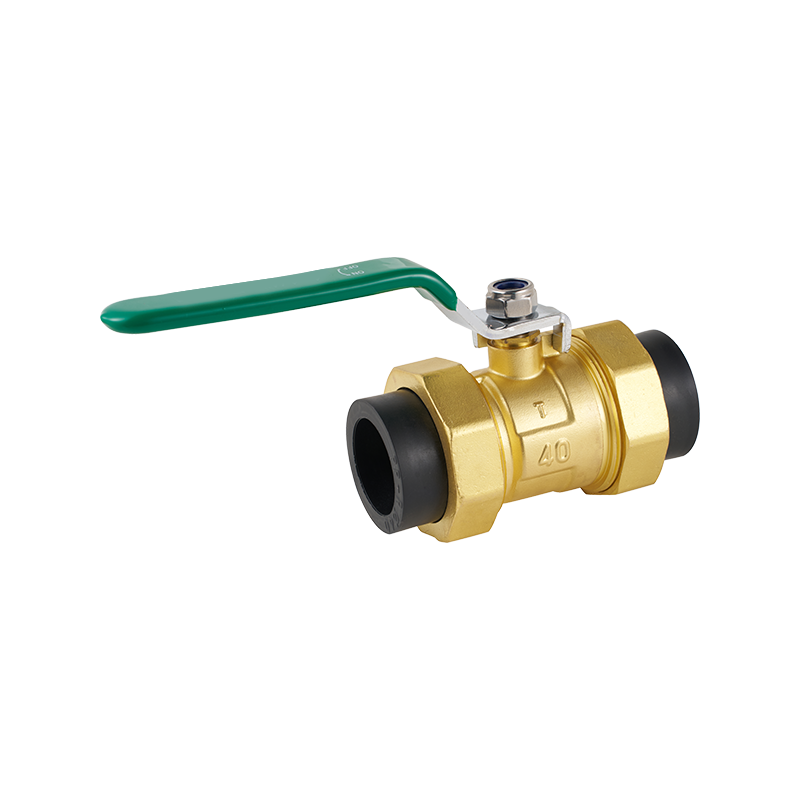

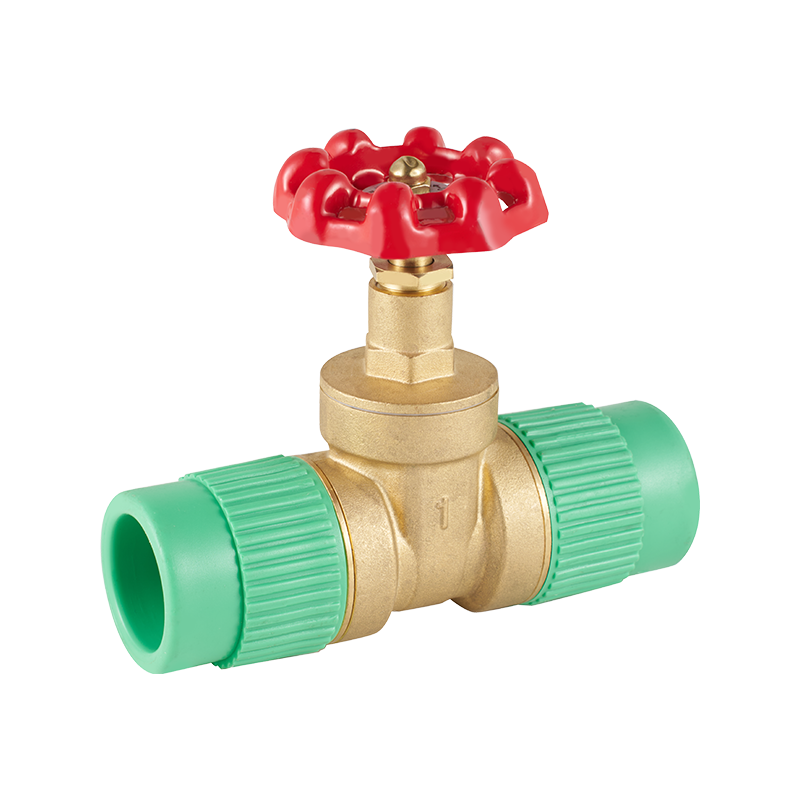

The compatibility of stainless steel manifolds with different types of piping, such as PEX or PP-R, is another practical consideration. Stainless steel manifolds often come with adapters or fittings designed to connect securely to plastic pipes commonly used in modern hydronic systems. This versatility simplifies installation and expands the range of applications for stainless steel manifolds, whether in new construction or retrofitting older systems.

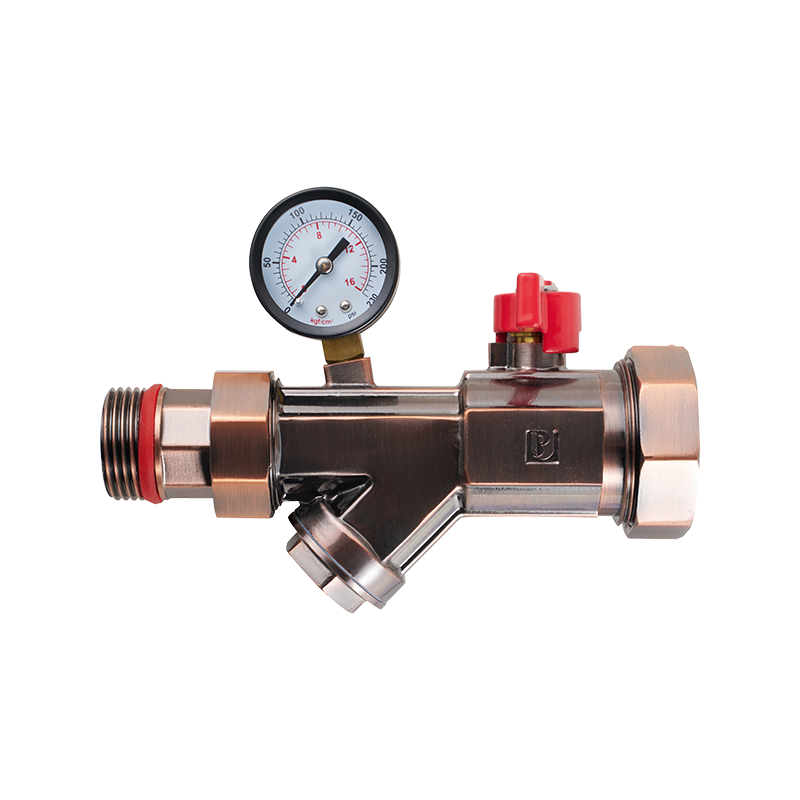

Moreover, stainless steel manifolds can be paired with accessories such as flow meters and air vents to enhance system control and reliability. Flow meters help in monitoring and adjusting water flow through each circuit, while automatic air vents remove trapped air that could otherwise cause noise or reduce heat transfer efficiency. These components, combined with the robustness of stainless steel, contribute to a balanced and trouble-free heating system.

In summary, stainless steel manifolds offer practical benefits for hydronic heating systems, including infloor heating applications. Their durability and resistance to corrosion support reliable water distribution, while integration with components like the 20 inch butterfly valve and 4 way gas valve allows for effective flow and fuel control. Careful design and installation of these manifolds help maintain system efficiency, ensure comfort, and extend the service life of heating equipment.

Choosing the right manifold system depends on the specific requirements of the heating project, but stainless steel remains a material that provides consistent performance under typical hydronic system conditions. Whether for residential infloor heating or larger commercial systems, stainless steel manifolds continue to serve as a dependable choice in the industry.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US