Heating systems are essential in many residential and commercial buildings, providing comfort and maintaining desired indoor temperatures. However, the long-term reliability of these systems depends heavily on the quality and performance of their components. Among the various parts that make up a heating system, valves play a crucial role in regulating flow, controlling gas supply, and maintaining safety. Understanding how to select and maintain these components is key to ensuring the heating system operates smoothly for years.

One important valve type commonly used in heating systems is the aluminium butterfly valve. Known for its relatively simple design and lightweight construction, this valve regulates the flow of fluids such as water or air by rotating a disc within the pipe. The use of aluminium offers corrosion resistance and helps reduce the overall weight of the valve, which can be beneficial in systems where reducing stress on pipes and supports is a priority. Proper installation of aluminium butterfly valves involves ensuring tight seals and correct alignment to prevent leaks or flow restrictions. Over time, routine inspection of these valves can identify wear on seals or buildup of debris, which may impair their function.

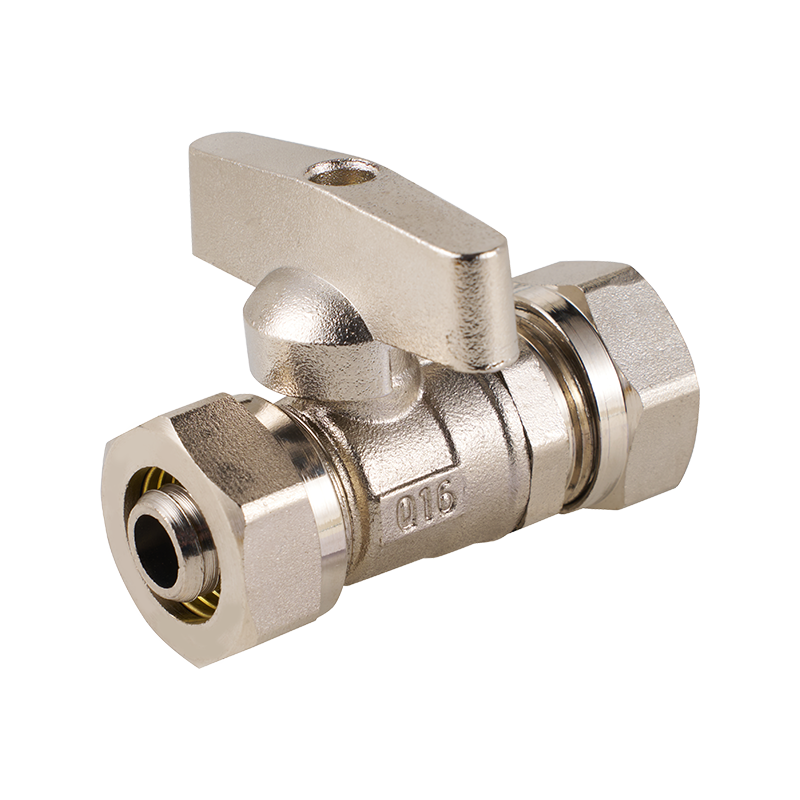

Another vital component in gas heating systems is the in line gas valve. These valves are installed directly along the gas supply line and serve to control or shut off the flow of gas. They must be designed to handle specific pressure and temperature conditions and meet safety standards due to the risks associated with gas leaks. Selecting an in line gas valve with reliable sealing and smooth operation reduces the chance of malfunction. Regular maintenance, including checking for leaks and ensuring the valve opens and closes fully, helps maintain system safety and efficiency.

In addition to standard gas valves, locking gas valves are frequently used to provide an extra layer of security. These valves feature a locking mechanism that prevents unauthorized or accidental operation, which is especially important in commercial or industrial environments. The locking feature ensures that only authorized personnel can manipulate the valve, reducing the risk of accidental gas shutoff or dangerous leaks. When installing locking gas valves, it is important to verify that the locking mechanism is robust and easy to operate during emergency situations. Periodic checks ensure that the lock remains functional and that the valve operates smoothly without obstruction.

Ensuring long-term reliability in heating system components goes beyond just choosing the right valves. Installation quality plays a significant role. Proper alignment, appropriate torque on fittings, and correct positioning can greatly affect how valves perform over time. Incorrect installation can cause stress on the valve body or seals, pilot to premature wear or failure. In addition, using compatible materials for pipes and valves prevents corrosion or chemical reactions that could compromise the system.

Maintenance routines tailored to the specific components are another important factor. For aluminium butterfly valves, cleaning to prevent sediment accumulation and inspecting the disc for signs of corrosion or damage can extend service life. In gas valves, regular leak testing using appropriate detection methods and ensuring the locking mechanisms on locking gas valves are intact can maintain safety standards. It is advisable to schedule inspections during seasonal system checks to catch potential issues early.

Environmental factors such as temperature fluctuations, humidity, and exposure to chemicals also impact the durability of heating system components. Aluminium valves can resist corrosion well but may suffer from mechanical wear in high vibration settings. Gas valves should be protected from freezing conditions and corrosive environments to maintain their sealing effectiveness. Designing the heating system with these environmental considerations in mind can reduce maintenance frequency and extend component life.

Technological advancements have introduced valves with improved materials and sealing technologies that enhance reliability. However, the fundamental principles of correct selection, proper installation, and regular maintenance remain the foundation for dependable heating systems. Operators and installers should be well-informed about the specifications and requirements of components such as aluminium butterfly valves, in line gas valves, and locking gas valves to make suitable choices for each project.

In conclusion, ensuring long-term reliability in heating system components is a multifaceted task. It involves selecting valves like aluminium butterfly valves for fluid regulation, in line gas valves for controlled gas flow, and locking gas valves for enhanced safety. Combined with careful installation, routine maintenance, and consideration of environmental impacts, these components contribute to stable and safe heating system performance. A proactive approach to component care can help prevent unexpected failures and maintain comfort without interruption.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US