Flow meters play a crucial role in improving the efficiency of manifolds used in various plumbing and heating systems. In particular, water underfloor heating manifold setups benefit significantly from the integration of flow meters, allowing for better control and balance of water distribution. When combined with components such as aluminum butterfly valves and angle gas valves, these systems can achieve more precise operation and increased longevity.

A manifold is essentially a hub that distributes water evenly across multiple circuits in a heating system, like underfloor heating. The efficiency of this distribution determines how well each area of the floor is heated and how energy is utilized. Flow meters help by providing a way to measure and regulate the flow of water going through each circuit. Without flow meters, it can be difficult to know if one circuit is receiving too much or too little water, which may cause uneven heating or wasted energy.

Integrating flow meters into a water underfloor heating manifold allows for visual or electronic monitoring of flow rates. This enables technicians or homeowners to make necessary adjustments, ensuring balanced flow throughout the system. For instance, if one room's heating circuit is receiving a higher flow rate than another, the flow meter reading will show this discrepancy. Adjusting the flow using valves can then balance the system and improve overall performance.

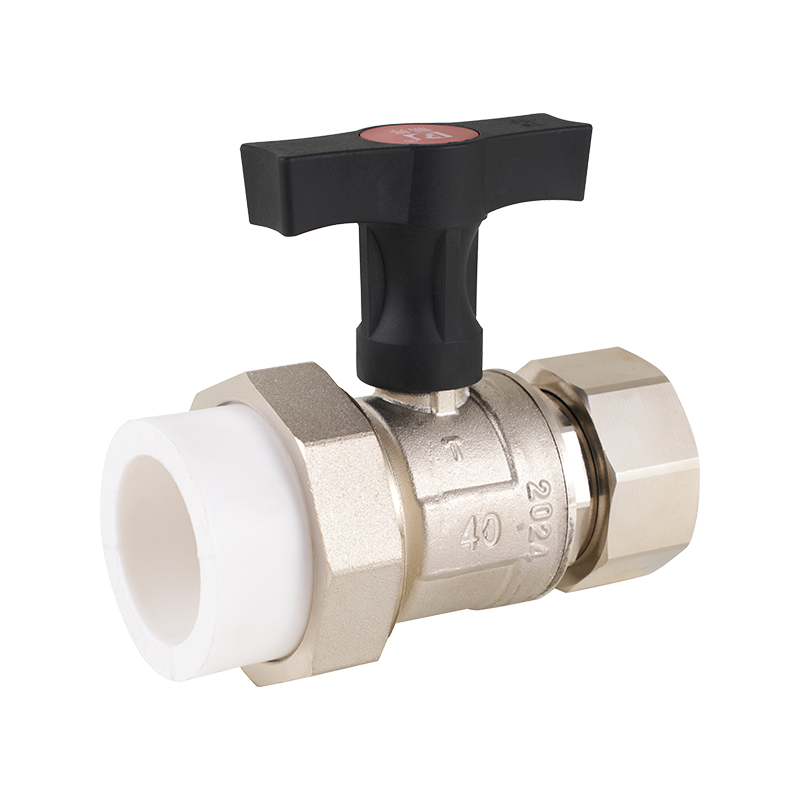

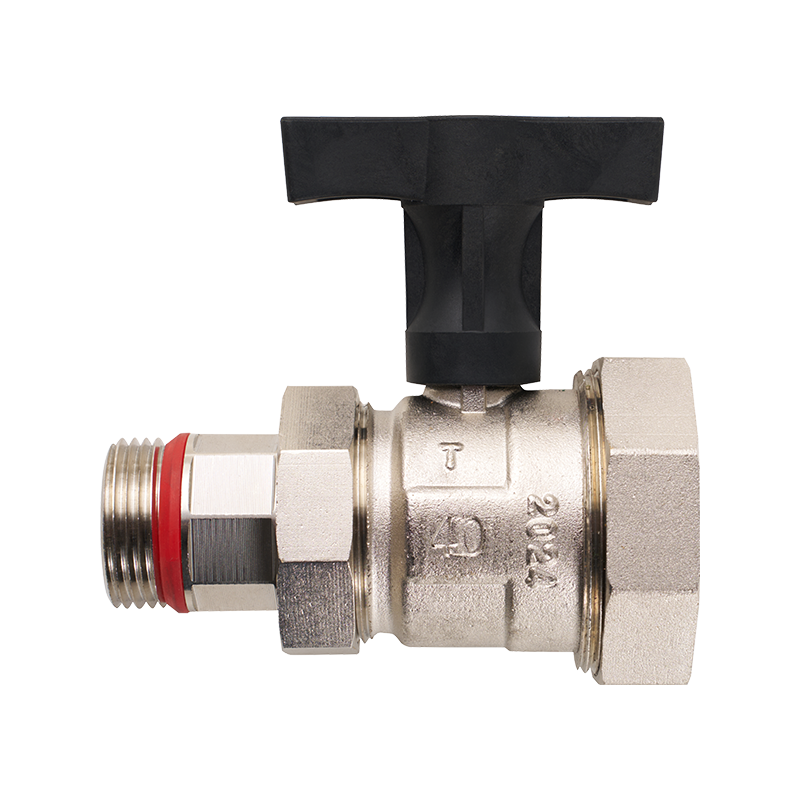

The aluminum butterfly valve is an important component in many manifold systems. Known for its lightweight and corrosion resistance, this valve type offers smooth control over water flow. Its design allows for quick opening and closing, which can be very useful when fine-tuning individual circuits on a manifold. When paired with flow meters, aluminum butterfly valves provide a practical way to control and regulate the flow based on actual measurements, rather than guesswork.

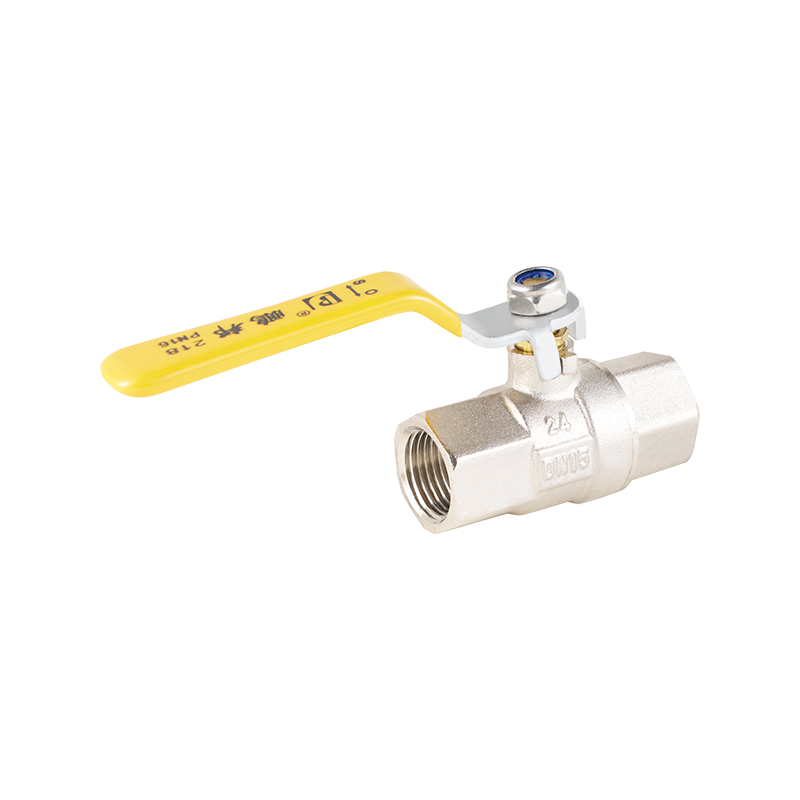

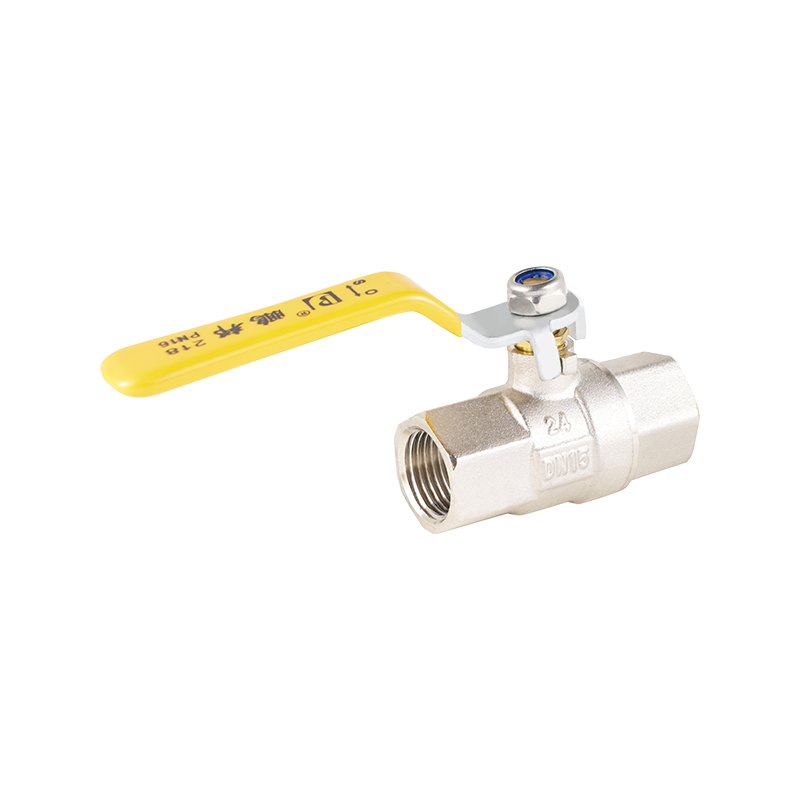

Moreover, in systems where gas is used alongside water heating, angle gas valves are often incorporated. These valves control the flow of gas entering heating appliances or components that work with the manifold system. Although angle gas valves are different from water control valves, their precision and reliability are essential for the safe and efficient operation of heating systems that use multiple energy sources. When a manifold includes both water circuits and gas components, coordinating the function of flow meters, aluminum butterfly valves, and angle gas valves becomes key to maintaining balance and safety.

The benefits of using flow meters on manifolds extend beyond just balanced heating. They also help in early detection of system issues such as blockages or leaks. A sudden change in flow rate detected by a flow meter can alert technicians to a problem before it causes significant damage or energy waste. This preventive capability supports longer system life and lower maintenance costs.

Another advantage is improved energy efficiency. When water flow is properly balanced, pumps and boilers can operate without overworking. The system delivers just the right amount of heat to each area, avoiding excessive energy use. This advances both cost savings and reduced environmental impact.

Installation of flow meters on a water underfloor heating manifold is typically straightforward and compatible with standard manifold components. These meters come in various types, from simple mechanical indicators to more advanced electronic devices that can connect to home automation systems. This flexibility allows for upgrades according to the needs and budgets of different users.

In conclusion, flow meters improve manifold efficiency by offering clear insights into water distribution, enabling precise control through valves like the aluminum butterfly valve, and supporting integrated systems that may also include angle gas valves. Their use in water underfloor heating manifolds enhances comfort, safety, and energy management. As heating systems become more sophisticated, incorporating reliable flow measurement tools will continue to be an important practice for achieving balanced and efficient operation.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US