In plumbing, industrial systems, and fluid management, the ability to regulate flow with accuracy directly impacts efficiency and safety. Two components central to this regulation are precision brass valves and engineered ball valves, each designed to address specific flow control needs. Their performance hinges on material science, design engineering, and practical functionality, making them integral to systems ranging from residential plumbing to industrial pipelines.

Precision Brass Valves: Material and Design Fundamentals

Precision brass valves are crafted from brass alloys, a combination of copper and zinc, chosen for properties that suit flow control. Brass offers corrosion resistance, particularly in water-based systems, where exposure to minerals and varying pH levels is common. This resistance helps maintain valve integrity over time, reducing the risk of leaks caused by material degradation.

Manufacturing precision is key to their function. These valves are machined to tight tolerances, ensuring components like stems, seats, and ports align accurately. This alignment minimizes leakage paths and ensures consistent flow rates when the valve is in partial or full open positions. For example, in residential water supply systems, a precision brass gate valve can be adjusted to deliver specific flow volumes, balancing pressure between fixtures like showers and faucets without sudden fluctuations.

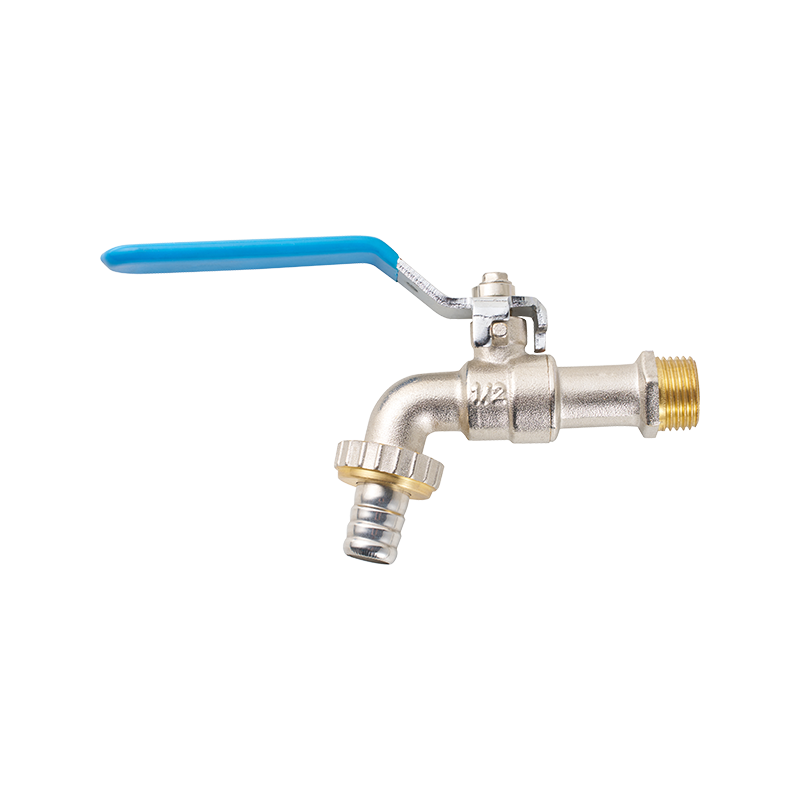

Brass’s malleability also plays a role in design versatility. It allows for intricate machining, enabling the production of valves in various sizes—from ½-inch residential models to 4-inch industrial versions—without compromising structural strength. This adaptability makes precision brass valves suitable for both low-pressure applications and moderate-pressure systems.

Engineered Ball Valve Control: Mechanisms and Flow Regulation

Engineered ball valves operate on a simple yet effective mechanism: a hollow, perforated ball connected to a handle. Rotating the handle turns the ball, aligning its perforation with the valve’s inlet and outlet to allow flow, or rotating it 90 degrees to block flow entirely. This design ensures quick, decisive control, a contrast to the gradual adjustment of gate or globe valves.

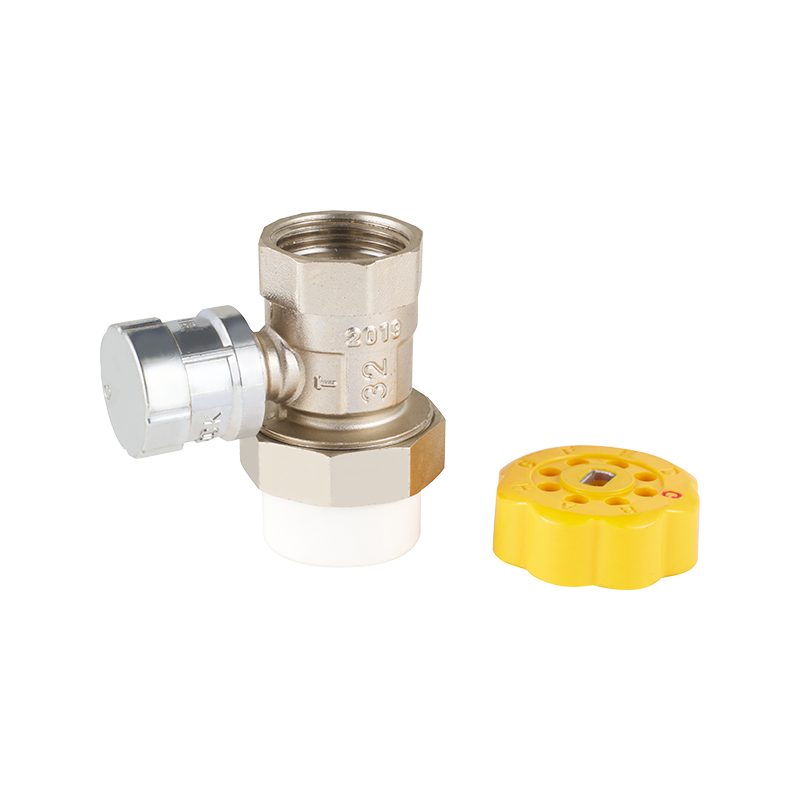

Engineering refinements enhance their functionality. The ball’s surface is often polished to reduce friction against the valve seats, ensuring smooth operation even after repeated use. Seats are typically made from materials like PTFE or rubber, chosen for compatibility with different fluids—PTFE works well with chemicals, while rubber is suited for water-based systems.

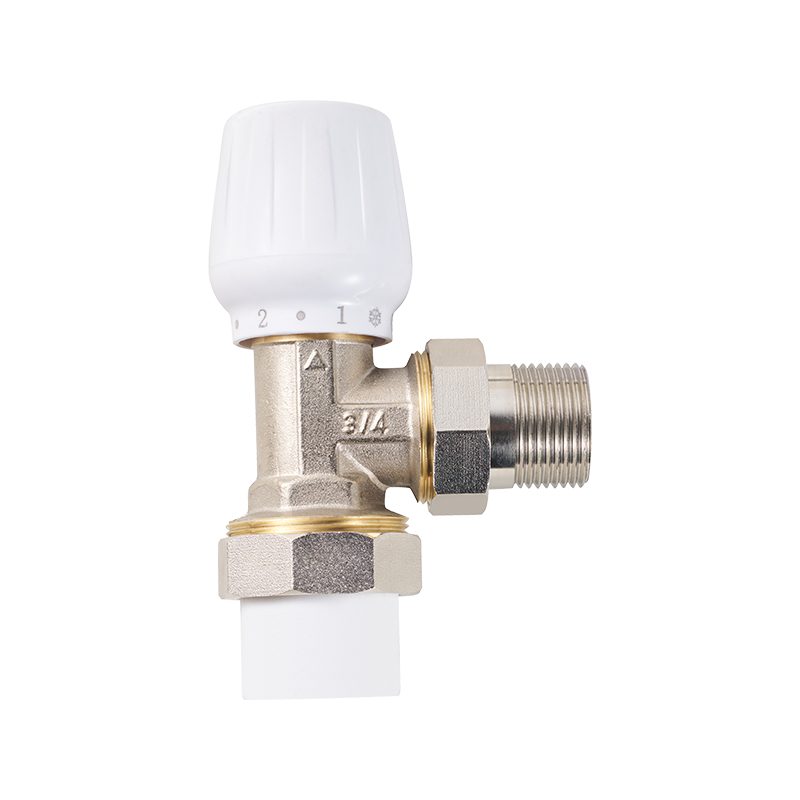

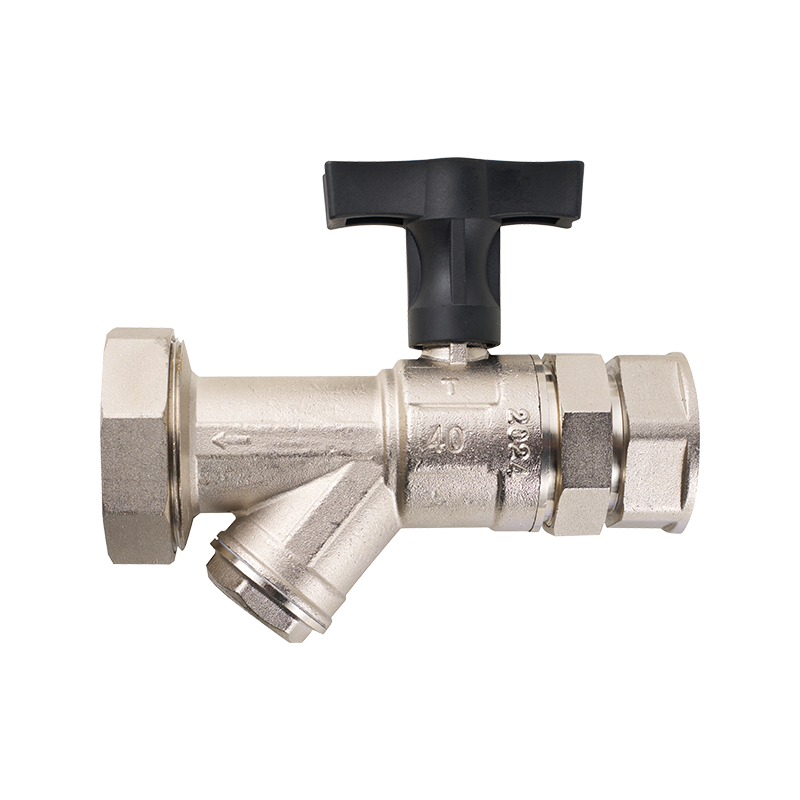

Flow regulation in engineered ball valves extends beyond full open/close. Some models include modified balls with V-shaped ports, allowing for throttling: partial rotation adjusts the port’s alignment, controlling flow volume incrementally. This makes them useful in applications where precise flow rates matter, such as in irrigation systems or industrial mixing processes, where too much or too little fluid can disrupt operations.

Practical Considerations for Installation and Use

Understanding compatibility is critical when selecting these valves. Precision brass valves, while corrosion-resistant, may not be ideal for highly acidic or alkaline fluids, as prolonged exposure can degrade the alloy. In such cases, engineered ball valves with stainless steel balls and chemical-resistant seats are often preferable.

Installation practices affect performance. Both valve types require proper sealing—using compatible gaskets or thread sealants—to prevent leaks. For brass valves, ensuring connections are not over-tightened is key; brass’s malleability means excessive force can warp threads, which may result in leaks. Ball valves, meanwhile, need their handles aligned correctly during installation to ensure the ball rotates freely without binding.

Maintenance needs are another practical concern. Precision brass valves benefit from periodic checks for mineral buildup, especially in hard water areas, where scale can restrict flow. Simple cleaning with mild descaling solutions helps maintain performance. Engineered ball valves require occasional lubrication of the stem to preserve smooth operation, particularly in high-use systems.

In fluid management systems, precision brass valves and engineered ball valves work in tandem to balance control and reliability. Their design nuances, material choices, and functional differences address diverse flow regulation needs, from residential plumbing to industrial processes, ensuring fluid systems operate as intended—consistently, safely, and efficiently.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US