Whether in residential plumbing, industrial piping, or commercial facilities, fluid systems rely on components that continuously regulate flow. Among these components, brass valves and ball valves stand out with their unique design features and functional advantages, enhancing system performance. Their role in controlling fluid flow is determined by material properties and mechanical design, making them crucial to maintaining system efficiency.

Brass Valves: Material Advantages in Fluid Control

Brass valves, made from brass (a copper-zinc alloy), offer unique advantages for fluid systems. This material's inherent corrosion resistance makes them suitable for water, oil, and certain chemicals, as they can withstand prolonged corrosion without significant performance degradation. This corrosion resistance helps maintain the long-term integrity of the valve, reducing the need for frequent valve replacement in systems with fluctuating fluid composition.

Brass's ductility enables precision manufacturing. Valves can be machined into complex shapes, and internal components like the valve seat and stem can be held to very tight tolerances. This precision ensures a secure seal when the valve is closed, reducing unwanted leakage. For example, in residential water systems, brass gate valves provide stable flow control, easily adjust to balance pressure between different devices, and prevent sudden pressure drops or spikes.

Brass also has good thermal conductivity, which is particularly useful in hot water systems. It can withstand temperature fluctuations and maintain proper function in environments with fluid temperatures ranging from low to near-boiling. This versatility allows brass valves to be integrated into a variety of installations, from under-sink plumbing to hot water systems.

Ball Valve: An Efficient Flow Control Mechanism

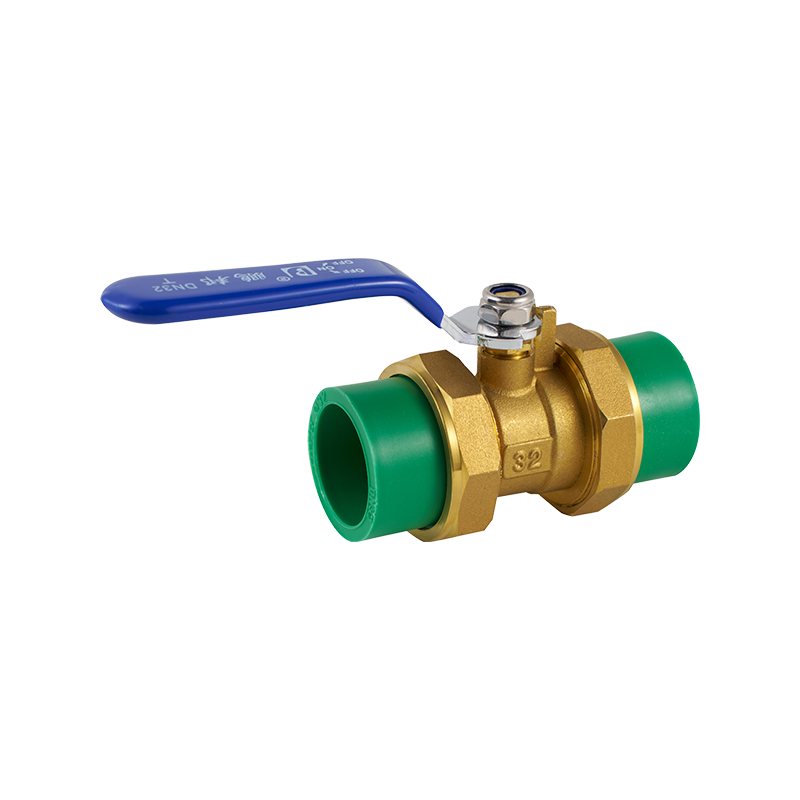

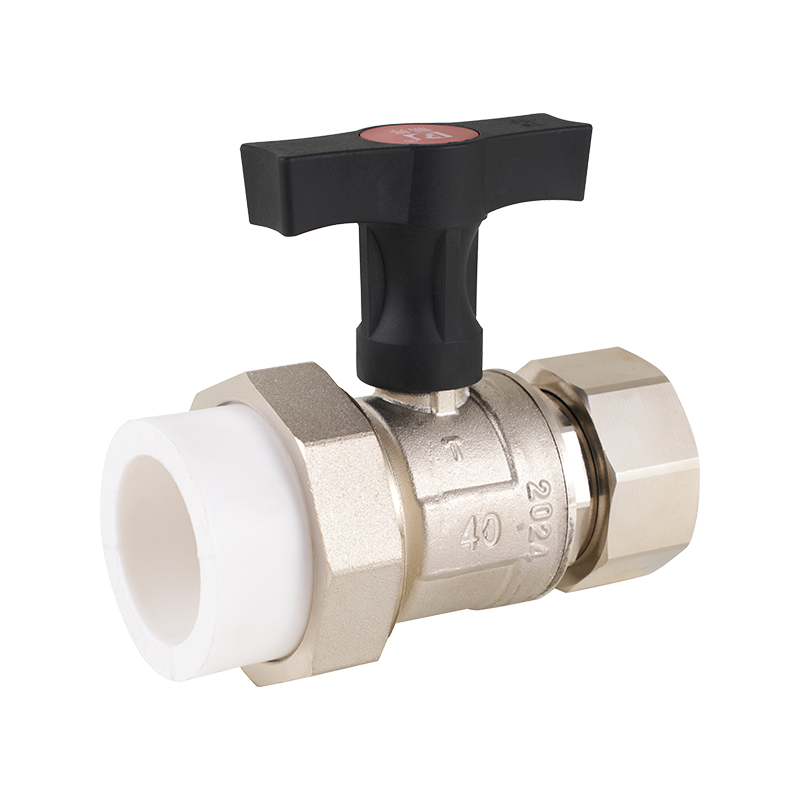

A ball valve utilizes a simple yet effective mechanism: a hollow ball with a central port attached to a lever handle. Turning the handle 90 degrees aligns the ports with the valve's inlet and outlet, allowing fluid flow. Rotating the handle backward seals the ports against the valve seats, completely stopping flow. This design allows for quick operation, which is crucial when shutting off flow immediately.

The ball valve's efficiency lies in its low pressure drop. When fully open, the port diameter matches the pipe size, reducing resistance to fluid flow. This feature makes it suitable for systems requiring constant flow, such as industrial processing lines or irrigation networks. Many ball valves utilize materials tailored for specific fluids. For example, a valve for chemicals might have seats made of an inert material like PTFE, while valves for water systems often have rubber seats to ensure a tight seal. The ball itself can be made of brass, stainless steel, or other metals, depending on the corrosiveness and temperature of the fluid.

How They Complement Each Other in Fluid Systems

Brass valves and ball valves often work together to enhance system performance. In residential plumbing, a brass shutoff valve near the water meter controls overall supply, while ball valves under sinks or behind appliances allow for localized shutoff during repairs. This combination balances broad regulation with targeted control, reducing disruption when maintenance is needed.

In industrial settings, brass valves may handle lower-pressure, smaller-diameter lines, such as those in lubrication systems, while ball valves manage higher-flow areas like main pipelines. The brass valves’precision in fine-tuning flow complements the ball valves’ability to handle large volumes efficiently.

Installation and maintenance practices further enhance their effectiveness. Brass valves require proper threading or soldering to ensure a tight fit, preventing leaks at connection points. Ball valves need periodic checks to ensure the lever moves freely, with occasional lubrication of the stem to maintain smooth operation. Both benefit from being installed in accessible locations, allowing for easy adjustment or replacement when necessary.

In fluid systems, the combination of brass valves and ball valves addresses a range of control needs. Their material properties and mechanical designs work in tandem to regulate flow, withstand system demands, and support efficient operation across residential, commercial, and industrial applications.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US