Demanding piping networks—found in industrial facilities, commercial buildings, and municipal systems—require components that balance durability, precision, and adaptability. Among these components, brass ball valves emerge as a critical link, merging the material advantages of brass with the mechanical efficiency of ball valve design. Their ability to perform under varying pressures, fluid types, and operational demands makes them a staple in systems where reliability directly impacts functionality.

Brass as a Foundation for Valve Performance

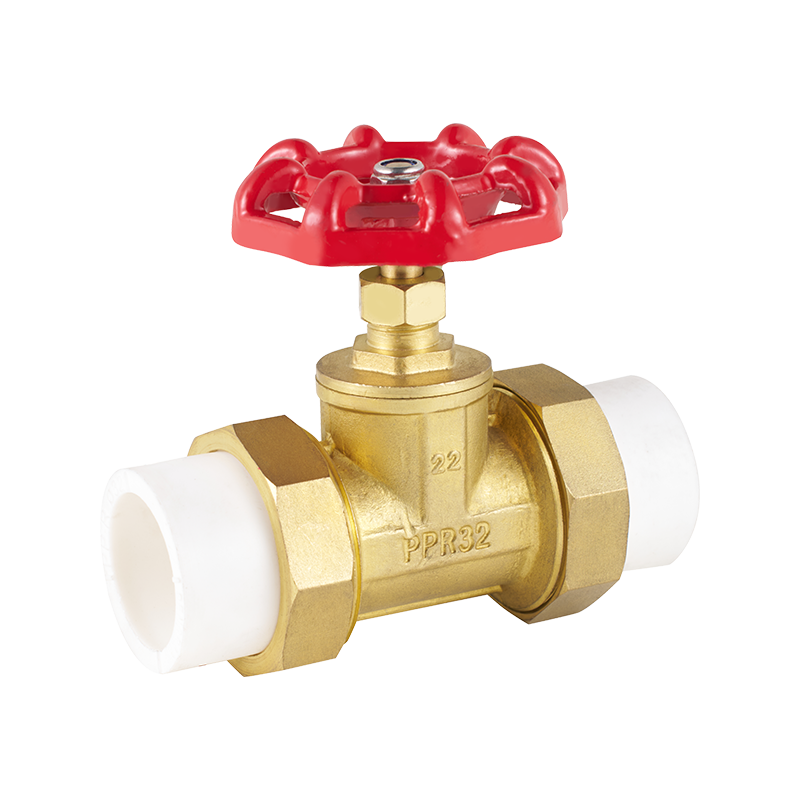

Brass, an alloy of copper and zinc, forms the base of these valves, contributing key properties to their performance in demanding networks. Its inherent resistance to corrosion stands out, particularly in systems handling water, mild chemicals, or oils. Unlike some metals, brass resists pitting and degradation when exposed to mineral-rich water or occasional chemical contact, helping maintain valve structure over extended periods. This resistance is valuable in industrial settings where fluid composition can shift, or in municipal water systems with fluctuating pH levels.

The alloy’s strength-to-weight ratio is another asset. Brass provides sufficient rigidity to withstand high pressures—common in industrial pipelines where fluid is pumped at elevated psi—without adding excessive weight to the system. This balance simplifies installation in overhead or vertical piping, where heavy components can strain supports. Additionally, brass’s malleability allows for precise machining, enabling tight tolerances in critical areas like valve seats and ball interfaces. This precision ensures a consistent seal when the valve is closed, reducing the risk of drips or leaks in systems where even small losses can disrupt operations.

Ball Valve Mechanisms: Efficiency in Flow Control

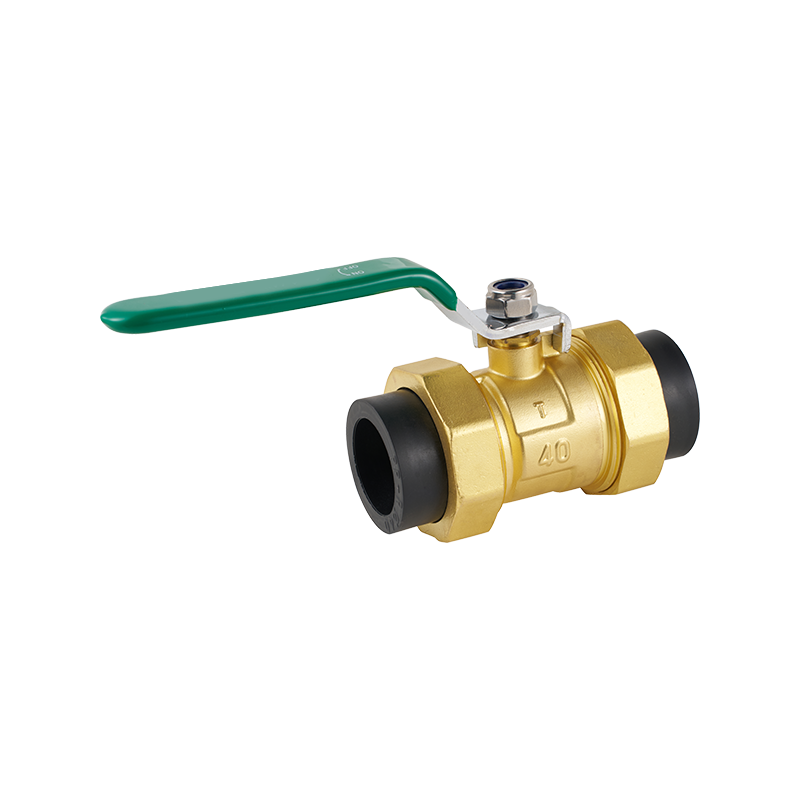

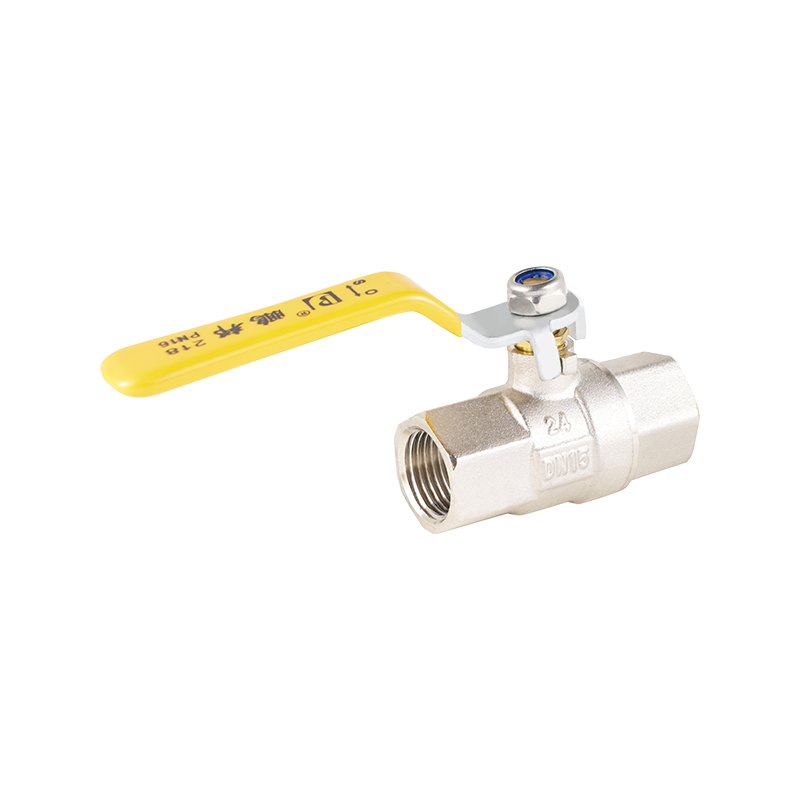

The ball valve mechanism enhances brass valves’ suitability for demanding networks through its operational design. At its core is a hollow, perforated ball connected to a lever handle. Rotating the handle 90 degrees aligns the ball’s perforation with the valve’s inlet and outlet, allowing fluid to flow; reversing the rotation seals the ball against the valve’s seats, halting flow. This 90-degree operation enables quick adjustments, a critical feature in emergency scenarios where rapid shutoff is needed—such as in industrial lines handling hazardous fluids.

The mechanism’s low pressure drop is equally important. When fully open, the ball’s perforation matches the pipeline’s diameter. This characteristic helps maintain consistent pressure throughout the network, avoiding energy waste in high-flow systems like commercial HVAC loops or industrial process lines. For example, in a manufacturing facility pumping coolant through machinery, a brass ball valve ensures coolant reaches equipment at intended pressures, preventing inefficiencies in temperature regulation.

Performance in Demanding Network Conditions

Brass ball valves excel in environments with fluctuating pressures and temperatures, common in demanding networks. They tolerate pressure ranges from low (residential-like 50 psi) to high (industrial 1,000+ psi), depending on size and design, making them adaptable to both commercial plumbing and heavy-duty industrial lines. Temperature resilience is another strength: brass retains its structural integrity in systems where fluids range from near-freezing to 250°F, a range typical in boiler feed lines or hot water distribution networks.

Their compatibility with diverse fluids adds to their utility. In municipal water treatment plants, they regulate flows of treated water, while in chemical processing facilities, they handle diluted acids or bases . This versatility reduces the need for multiple valve types in mixed-fluid networks, simplifying inventory and maintenance.

Practical Considerations for Network Integration

Demanding piping networks—found in industrial facilities, commercial buildings, and municipal systems—require components that balance durability, precision, and adaptability. Among these components, brass ball valves emerge as a critical link, merging the material advantages of brass with the mechanical efficiency of ball valve design. Their ability to perform under varying pressures, fluid types, and operational demands makes them a staple in systems where reliability directly impacts functionality.

Brass as a Foundation for Valve Performance

Brass, an alloy of copper and zinc, forms the base of these valves, contributing key properties to their performance in demanding networks. Its inherent resistance to corrosion stands out, particularly in systems handling water, mild chemicals, or oils. Unlike some metals, brass resists pitting and degradation when exposed to mineral-rich water or occasional chemical contact, helping maintain valve structure over extended periods. This resistance is valuable in industrial settings where fluid composition can shift, or in municipal water systems with fluctuating pH levels.

The alloy’s strength-to-weight ratio is another asset. Brass provides sufficient rigidity to withstand high pressures—common in industrial pipelines where fluid is pumped at elevated psi—without adding excessive weight to the system. This balance simplifies installation in overhead or vertical piping, where heavy components can strain supports. Additionally, brass’s malleability allows for precise machining, enabling tight tolerances in critical areas like valve seats and ball interfaces. This precision ensures a consistent seal when the valve is closed, reducing the risk of drips or leaks in systems where even small losses can disrupt operations.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US