Among the various types available, brass ball valves have emerged as a staple in diverse applications, thanks to their unique combination of material properties and design features. These valves, which utilize a spherical ball to control the flow of fluids, have gained traction across industries ranging from residential plumbing to industrial processing. With a focus on meeting the varied needs of piping systems, certified brass ball valve products stand out as a viable option for those seeking consistent performance in their fluid control setups.

Material Advantages of Brass in Ball Valve Construction

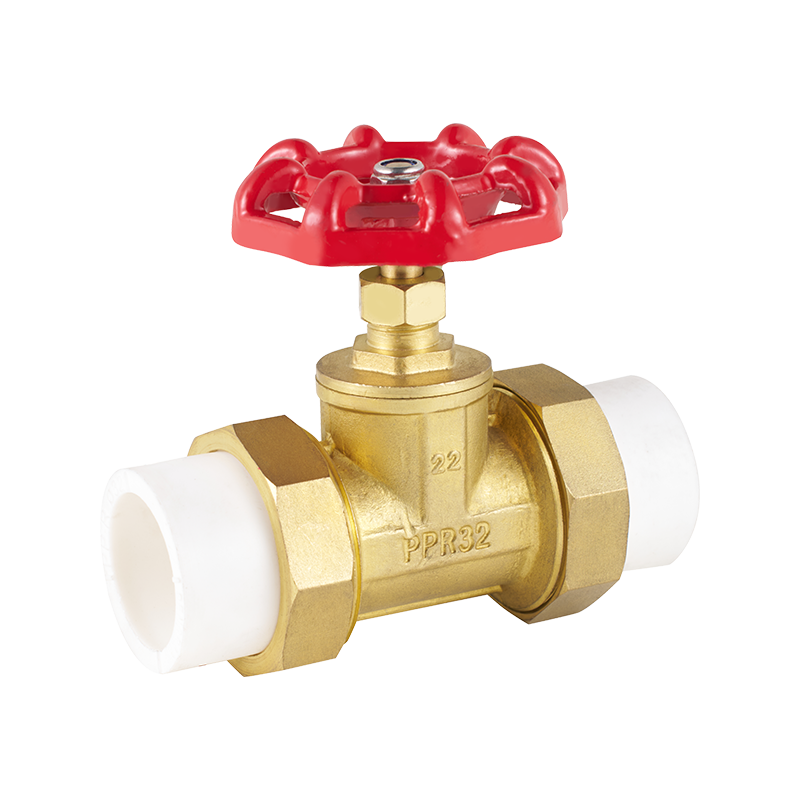

Brass, an alloy primarily composed of copper and zinc, brings a host of benefits to ball valve manufacturing. Its inherent corrosion resistance makes it suitable for use with a wide range of fluids, including water, oils, and certain chemicals. This resistance helps maintain the valve's integrity over time, even in environments where exposure to moisture or corrosive substances is common. Additionally, brass exhibits good thermal conductivity, allowing the valve to handle temperature variations without significant expansion or contraction that could compromise its functionality. The material's malleability also enables precise machining, ensuring that the spherical ball and valve body fit together with tight tolerances, which is crucial for minimizing leakage. These material properties collectively contribute to the durability of brass ball valves, making them a long-lasting choice for various piping requirements.

Design Features Enhancing Flow Control

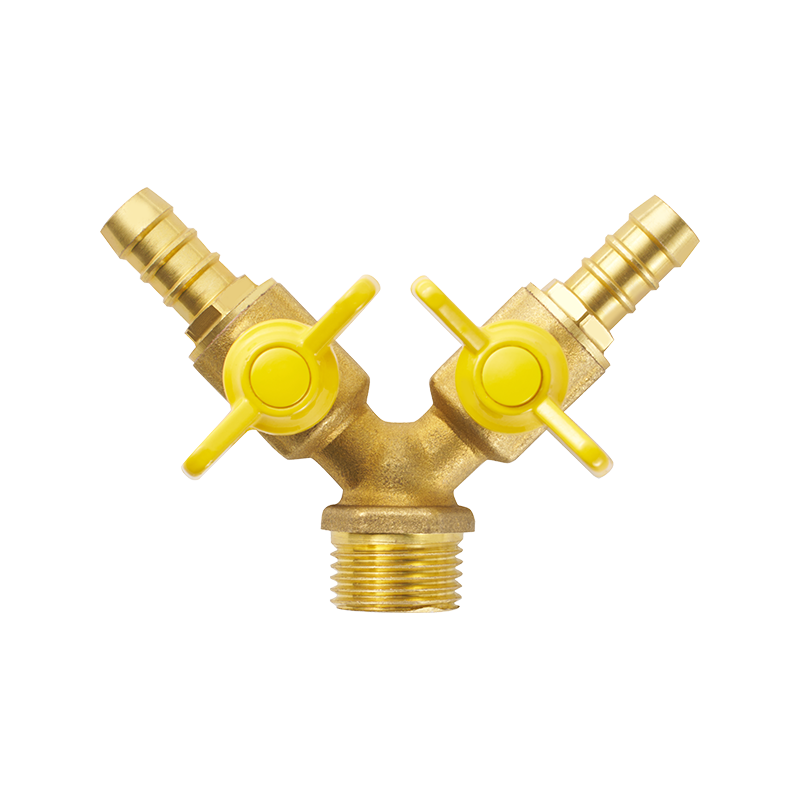

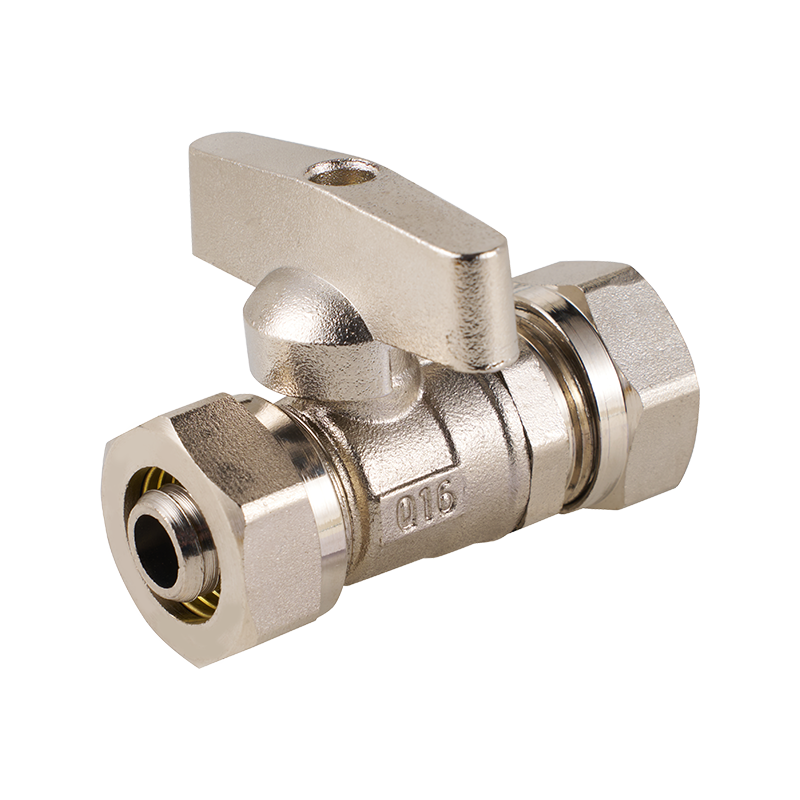

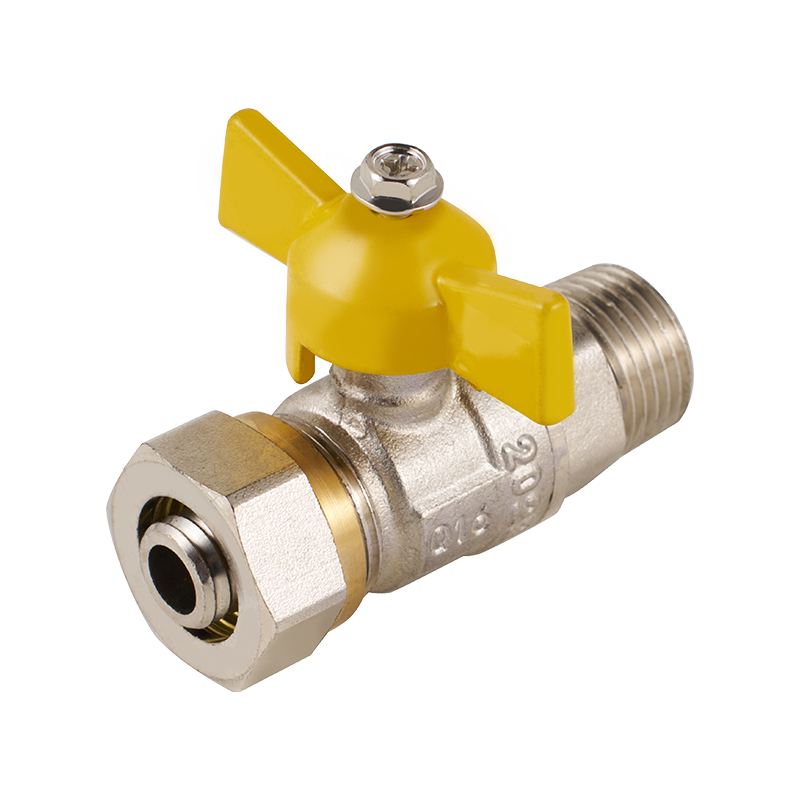

The design of brass ball valves is centered around providing efficient flow control. The core component, the ball, features a bore through its center. When the valve handle is turned, the ball rotates, aligning the bore with the pipe to allow fluid flow or positioning it perpendicular to block the flow. This straightforward operation ensures quick on-off functionality, which is essential in applications where rapid flow adjustment is needed. The compact design of brass ball valves also makes them easy to install in tight spaces, a key advantage in both residential and commercial plumbing systems where space constraints are often a consideration. Furthermore, the inclusion of seals, typically made from materials like Teflon or rubber, ensures a tight shut-off when the valve is closed, preventing unnecessary fluid loss. These design elements work in tandem to provide reliable flow control across different pressure and flow rate conditions.

Certification Standards Ensuring Quality and Safety

Adherence to recognized quality management systems ensures that the valves are manufactured under consistent processes that meet industry benchmarks. For instance, compliance with international quality standards involves rigorous testing of materials, production processes, and finished products. This includes checks for dimensional accuracy, pressure resistance, and leakage rates.Environmental management certifications also come into play, ensuring that the manufacturing process reduces environmental impact, from raw material sourcing to waste disposal. Occupational health and safety certifications further guarantee that the production facilities maintain safe working conditions, which indirectly contributes to the quality of the final product. These certifications provide end-users with confidence that the brass ball valves they select have undergone thorough evaluation and meet established criteria for performance and safety.

Applications Across Diverse Piping Systems

Brass ball valves find application in a wide array of piping systems due to their versatility. In residential settings, they are commonly used in plumbing lines for controlling water flow to fixtures such as sinks, showers, and toilets. Their corrosion resistance makes them suitable for both cold and hot water lines. In commercial buildings, these valves are employed in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of refrigerants or heating fluids. Industrial environments also benefit from brass ball valves, where they are used in processing lines for chemicals, oils, and other industrial fluids, provided the fluid is compatible with brass. Additionally, their use extends to irrigation systems, where they help control the distribution of water to agricultural fields. The ability to function effectively across such a broad spectrum of applications underscores the adaptability of brass ball valves to diverse piping requirements.

Compatibility with Various Fluids and Operating Conditions

One of the key strengths of brass ball valves is their compatibility with a range of fluids and operating conditions. They perform well with water, whether it is potable water in residential systems or process water in industrial settings. Mineral oils and certain petroleum-based fluids can also be handled by these valves, making them useful in automotive and machinery applications. When it comes to operating pressure, brass ball valves are capable of withstanding moderate to high pressures, depending on their size and design, which allows them to be integrated into both low-pressure residential systems and higher-pressure industrial setups. Temperature-wise, they can tolerate a range of temperatures, from the cold water in plumbing lines to the higher temperatures found in some industrial processes. This broad compatibility ensures that brass ball valves can be effectively utilized in numerous scenarios, adapting to the specific fluid and operating conditions of each application.

Brass ball valves presence in various industries and applications is a testament to their ability to meet the practical needs of fluid control systems, providing a balance of performance and durability that remains relevant in modern piping setups.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US