In the complex network of modern fluid management systems, the synergy between material science and engineering design determines the efficiency of flow control. Brass valves, known for their adaptability, and ball valves, recognized for their precise operation, together form a solution that addresses a wide spectrum of industrial and residential needs. This combination brings together the inherent properties of brass with the mechanical accuracy of ball valve design, creating components that fit into diverse piping environments while maintaining consistent performance.

The Material Foundation: Brass in Valve Construction

Brass, an alloy of copper and zinc, serves as a foundational material for valve manufacturing due to its unique set of characteristics. Its resistance to corrosion makes it suitable for contact with various fluids, including water, mild chemicals, and petroleum-based substances. This resistance reduces the risk of degradation over time, even in environments where moisture or chemical exposure is ongoing. Brass also offers good thermal stability, allowing valves to operate across a range of temperatures without significant structural changes. The material’s machinability enables the creation of intricate components with tight tolerances, a critical factor in ensuring proper sealing and flow control. These properties make brass a material that adapts to different operating conditions, from residential plumbing to light industrial applications.

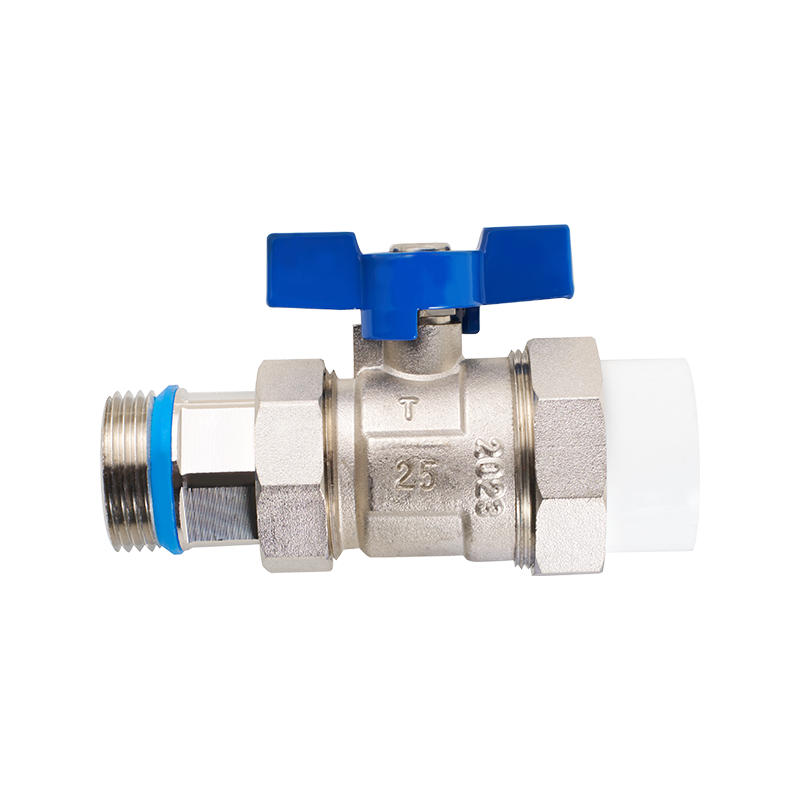

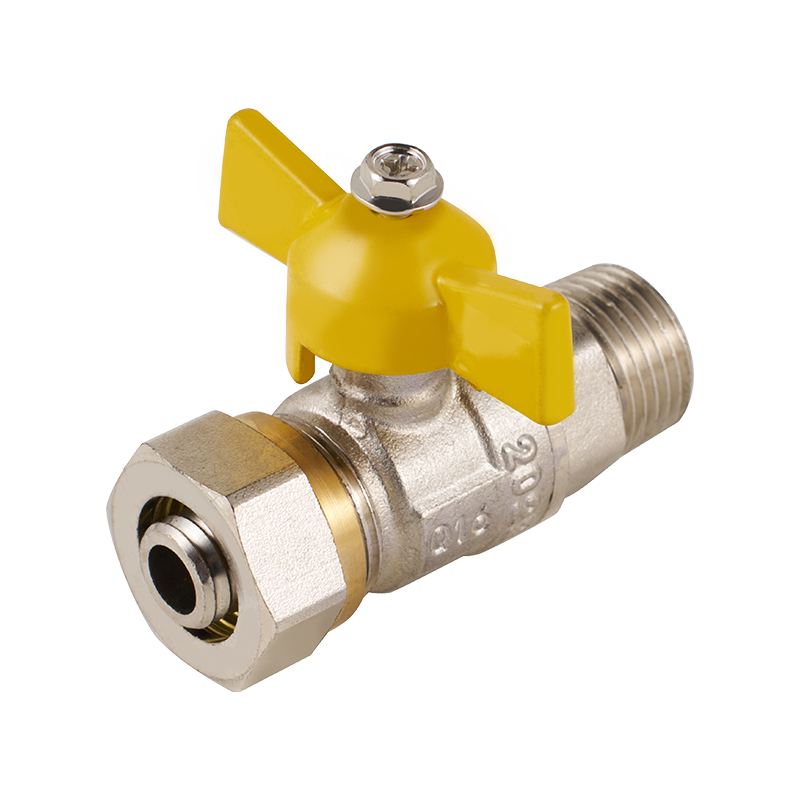

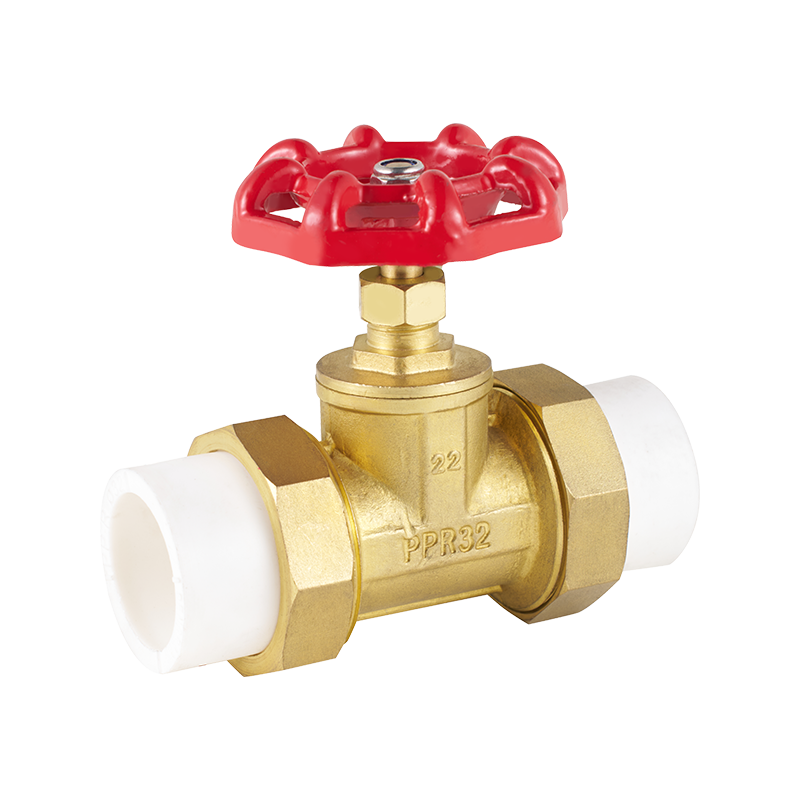

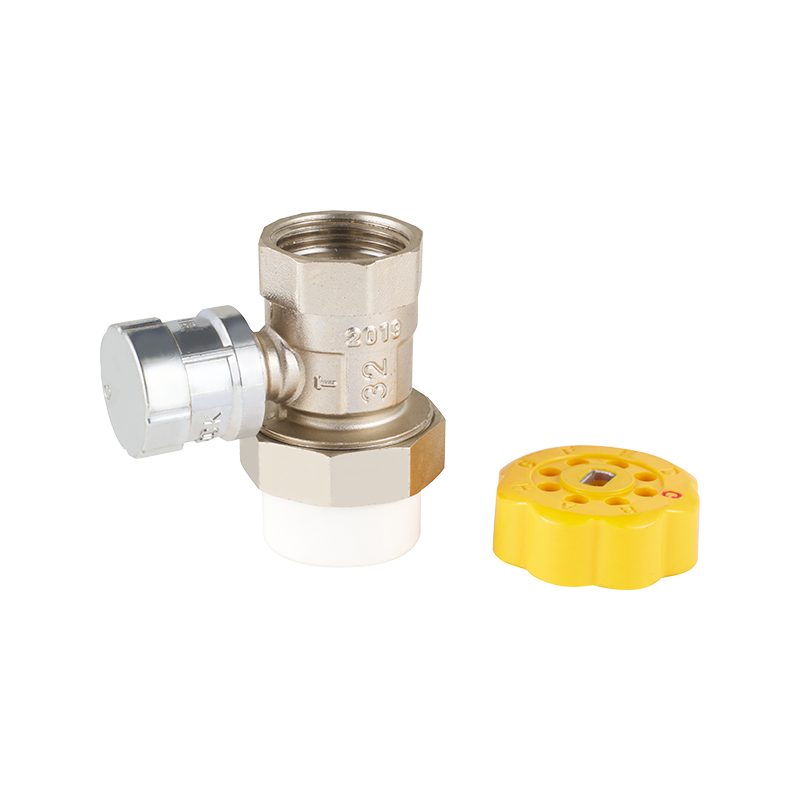

Ball Valve Design: Precision in Flow Regulation

Ball valves operate on a simple yet effective mechanical principle: a hollow sphere (the ball) within the valve body rotates to control flow. When the ball’s hollow center aligns with the pipe, fluid passes through; when rotated 90 degrees, the solid part of the ball blocks the flow. This design facilitates quick on-off operation, with reduced pressure drop when fully open.The precision of this mechanism comes from the tight fit between the ball and the valve seats, typically made from materials like PTFE or rubber, which prevent leakage when closed. The compact structure of ball valves also makes them easy to integrate into existing systems, requiring less space than other valve types. This precision extends to their operation, as the rotational movement allows for exact positioning, making them suitable for applications where flow needs to be adjusted with accuracy.

Versatility Across Applications

The combination of brass material and ball valve design results in components that function across a variety of settings. In residential plumbing, these valves control water flow to fixtures, handling both hot and cold water lines. Their corrosion resistance makes them suitable for long-term use in these systems, where contact with minerals in water is constant. In commercial buildings, they find use in HVAC systems, regulating the flow of refrigerants or heating fluids. Industrial settings, such as food processing or light manufacturing, utilize them to manage the flow of compatible liquids, leveraging their ability to maintain hygiene and prevent contamination. Even in agricultural applications, brass ball valves are used in irrigation systems, where they withstand exposure to outdoor elements while controlling water distribution. This broad applicability stems from their ability to adapt to different pressures, temperatures, and fluid types.

Certifications and Compliance

Adherence to industry standards ensures that brass ball valves meet specific performance and safety criteria. Certifications related to quality management systems verify that manufacturing processes are consistent, resulting in valves that perform as intended. Environmental certifications address the impact of production, ensuring that materials and processes minimize ecological footprint. Health and safety certifications confirm that valves are safe for use in environments where human contact is likely, such as potable water systems. These certifications also often include testing for factors like pressure resistance, leakage rates, and material compatibility, providing users with documentation of a valve’s capabilities. Compliance with such standards is not just a formality but a practical assurance that the valve will function within specified parameters, reducing the risk of failure in critical systems.

Maintenance and Longevity

Brass ball valves are designed for durability with minimal maintenance requirements. Their solid construction reduces the need for frequent repairs, and the materials used resist wear from repeated operation. Routine maintenance typically involves periodic inspection of the valve seats and stems for signs of wear, along with lubrication of moving parts in some models. This ease of maintenance contributes to their long service life, making them a cost-effective choice over time. The ability to disassemble and replace components, such as seats or handles, further extends their usability, allowing for repairs without replacing the entire valve. This focus on longevity ensures that they remain functional for years, even in high-use applications.

The integration of brass versatility and ball valve precision creates a flow control solution that balances adaptability with accuracy. Their presence in diverse systems—from homes to industries—speaks to their ability to meet practical needs, providing reliable performance without compromising on functionality. As fluid management systems continue to evolve, these valves remain a steady component, offering a combination of properties that few other valve types can match.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US