Flow control systems in industrial pipelines often rely on durable and adaptable valve solutions. Among these, the butterfly valve and the double union ball valve are frequently selected for their practical features, ease of installation, and ability to manage different types of media. While both have their own strengths, butterfly valves are particularly recognized for their efficiency in regulating flow across a wide range of applications.

Structural Simplicity and Space Efficiency

Butterfly valves are designed with a disc that rotates on a central axis, allowing the operator to control fluid passage with a quarter-turn motion. This compact design makes them lighter than many alternative valve types and helps save space in crowded piping systems. In industries where pipelines run across limited layouts, such as water treatment facilities or chemical plants, the ability to integrate a valve without requiring extensive clearance is a practical advantage.

Effective Flow Regulation

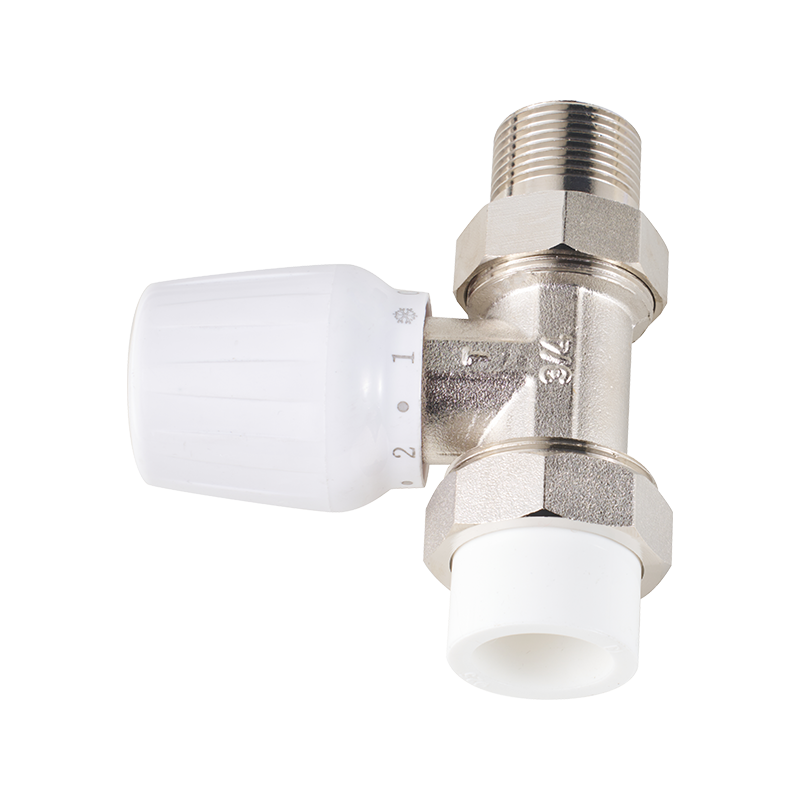

Unlike valves designed primarily for shutoff, butterfly valves are highly suited for throttling applications. The disc can be positioned at various angles, offering incremental control over flow rates. This makes them particularly useful in systems where fluid volume must be adjusted frequently to maintain process stability. When compared with double union ball valves, which are better suited for on-off control and easy disassembly, butterfly valves excel in scenarios that demand constant regulation.

Range of Sizes and Pressure Adaptability

Butterfly valves are manufactured in a wide range of diameters, from small units for localized systems to large-scale valves used in municipal water distribution. Their construction enables them to handle moderate to high pressures depending on the selected material and sealing method. For industries such as power generation or oil and gas, this adaptability ensures that butterfly valves can be incorporated into both primary and auxiliary pipelines without compromising performance.

Maintenance and Service Considerations

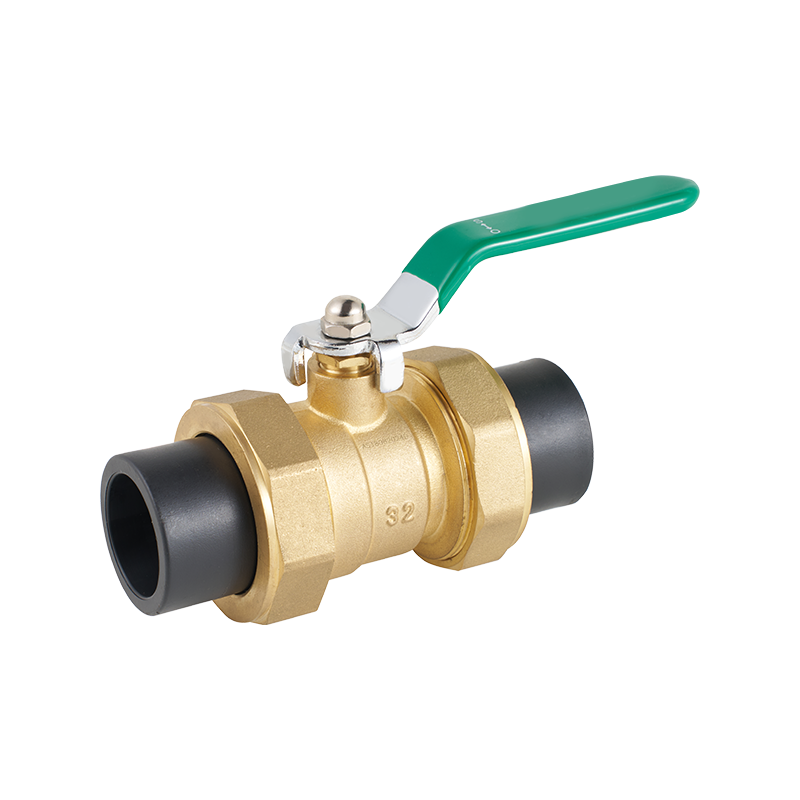

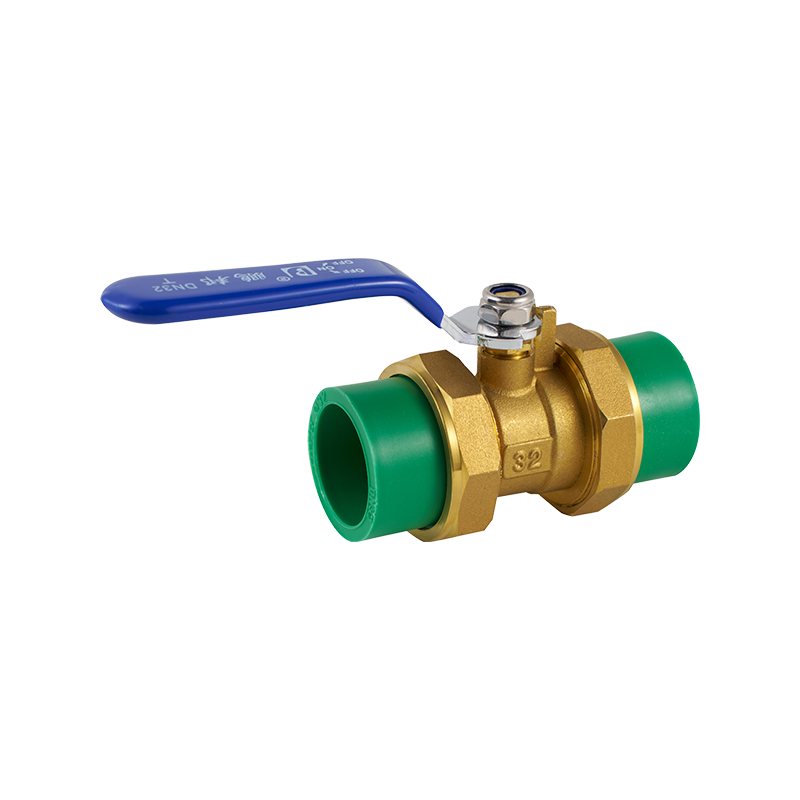

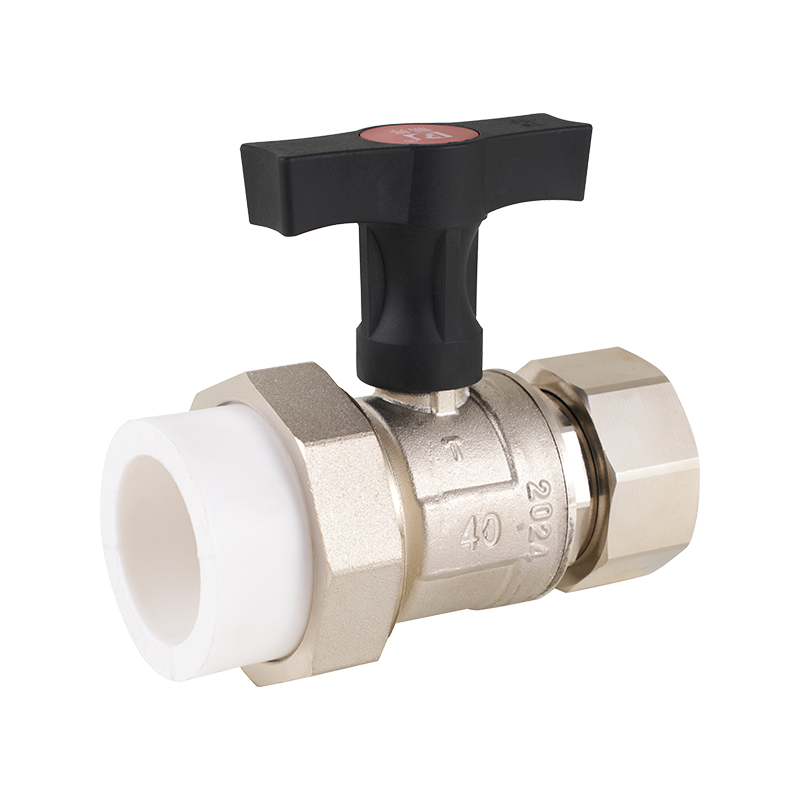

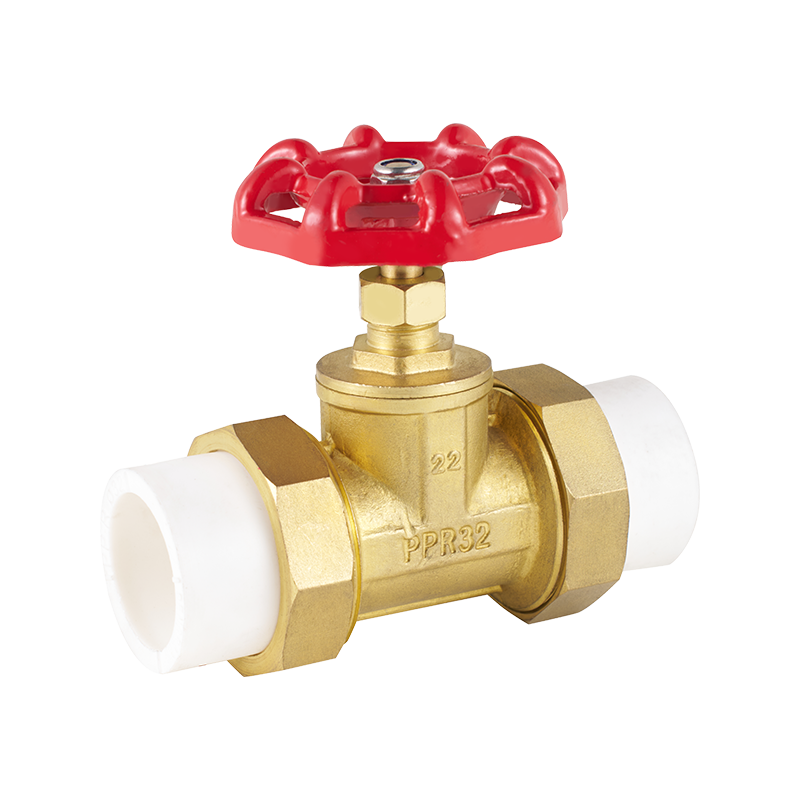

Routine serviceability is a key factor in valve selection. A double union ball valve offers convenience for systems that require quick disconnection and reinstallation, especially in residential plumbing or laboratory setups. Butterfly valves, on the other hand, stand out for their straightforward maintenance. Because they consist of fewer moving parts, inspection and replacement of seals can often be completed without specialized tools, reducing downtime in industrial environments.

Energy Efficiency Through Reduced Pressure Drop

In a fully open position, the disc aligns closely with the direction of the flow, creating relatively low resistance. This contributes to reduced energy consumption by pumps, which can make a measurable difference in facilities that transport large volumes of fluid. When flow efficiency is a priority, butterfly valves help maintain system balance without excessive energy demand.

Material Options for Different Applications

The versatility of butterfly valves is further enhanced by the range of materials available for construction. Bodies can be produced from cast iron, stainless steel, or high-grade alloys, while seals and liners may include rubber, PTFE, or other corrosion-resistant options. This allows engineers to match the valve to specific media, whether water, gases, or chemical solutions. Similarly, double union ball valves are often chosen for systems carrying aggressive chemicals, where removable connections simplify replacement without dismantling surrounding pipework.

Integration with Automation Systems

Modern processing industries increasingly depend on automated flow control. Butterfly valves are compatible with both manual actuators and advanced automation setups, including pneumatic and electric systems. Their lightweight design reduces actuator requirements, which can lower installation costs and simplify control integration. For projects involving distributed control systems, butterfly valves provide a practical solution for precise operation without excessive hardware.

Balancing the Role of Different Valve Types

While butterfly valves offer significant benefits in regulating flow, the role of double union ball valves remains valuable in applications where easy disassembly, cleaning, or replacement is necessary. In many fluid systems, both valve types are used together to complement each other’s strengths. Butterfly valves handle the continuous regulation and larger volumes, while double union ball valves are positioned where maintenance access is essential. This combination helps engineers design efficient and flexible piping networks.

Butterfly valves continue to play a key role in enhancing flow control efficiency by combining space-saving design, adaptable operation, and compatibility with automation. When applied alongside double union ball valves in well-planned systems, they provide engineers and operators with dependable tools to manage diverse industrial and commercial fluid processes effectively.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US