Across industrial and commercial piping systems, choosing between a butterfly valve and a double union ball valve often depends on the specific requirements of the application. Both are well-established solutions in fluid control, but butterfly valves are frequently highlighted for their efficiency in handling large volumes of fluid with straightforward operation. It is useful to examine their design features, performance characteristics, and the types of systems where they are commonly installed.

Space-Saving Design for Large Pipelines

One of the reasons butterfly valves are widely adopted is their compact construction. Unlike bulky valve types, they occupy less space and require minimal clearance for installation or operation. This makes them suitable for large-scale pipelines in municipal water treatment plants, power stations, and district heating systems where space is often restricted. In contrast, double union ball valves are more commonly used in smaller-scale or modular systems where frequent disassembly and reassembly are necessary.

Effective Flow Regulation in Process Systems

Butterfly valves are often selected for applications where flow needs to be regulated rather than simply switched on or off. The rotating disc can be positioned at multiple angles, allowing operators to fine-tune the fluid passing through the pipeline. This function is valuable in chemical processing, food production, or HVAC systems, where maintaining a controlled flow rate is critical for efficiency. While double union ball valves are efficient for quick shutoff, butterfly valves offer smoother control for ongoing operations.

Suitability for Water and Wastewater Applications

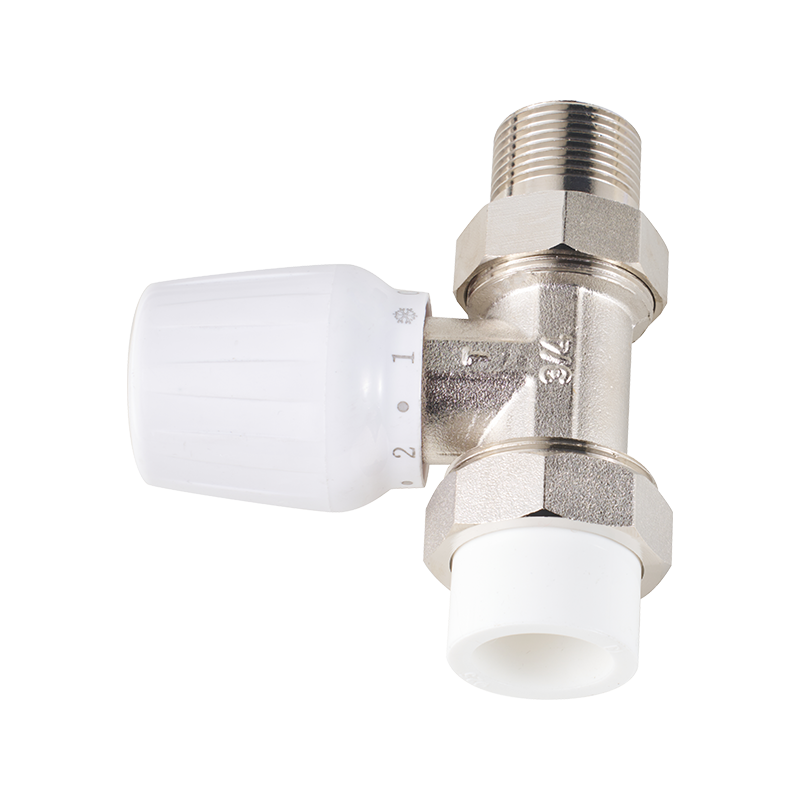

Municipal water supply and wastewater treatment plants frequently rely on butterfly valves due to their ability to handle large diameters and varying flow conditions. In these environments, maintenance is also simplified because butterfly valves have fewer components to service. On the other hand, double union ball valves are commonly placed in smaller service lines or laboratory setups where easy removal and cleaning are priorities.

Adaptability in High-Volume Industrial Use

Industries that deal with high-volume transport of gases or liquids, such as petrochemical facilities and marine systems, often favor butterfly valves. Their structure allows them to be scaled up in size without becoming excessively heavy, making them practical for handling bulk flow. The versatility in material options, from stainless steel to lined versions for corrosive media, further extends their usefulness. Double union ball valves serve a different role in such settings, often positioned in areas where compact isolation valves are needed for sections of the system.

Integration with Automated Control Systems

As automation becomes more common across industries, butterfly valves have proven adaptable to different actuation methods. They can be operated manually, pneumatically, or electrically, depending on system design. This flexibility makes them suitable for remote operation in large facilities, where direct manual access is limited. Double union ball valves are also compatible with automation but are often used where modular connections and quick replacements are required.

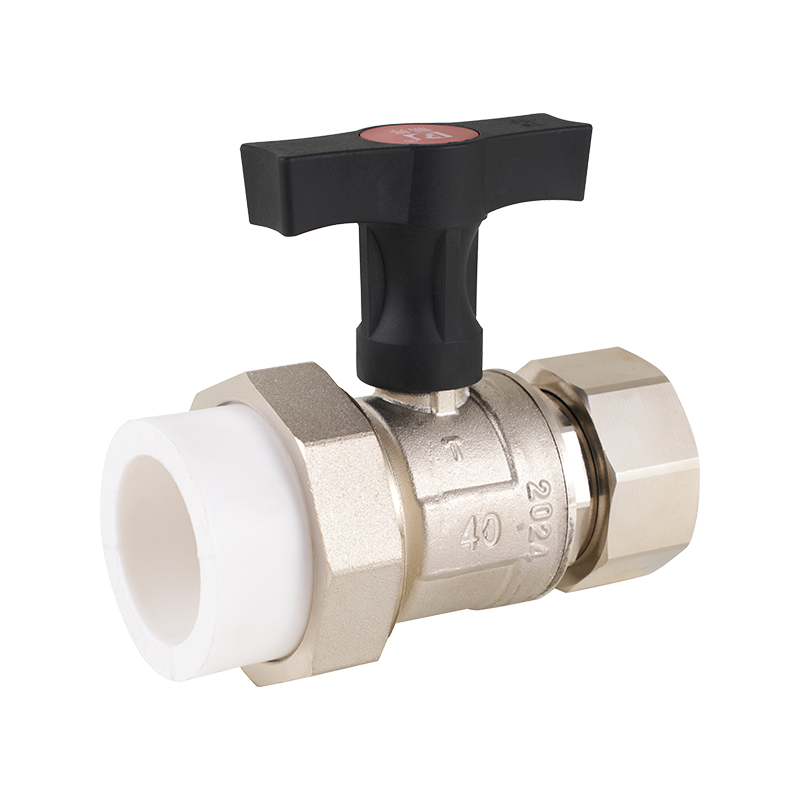

Cost and Maintenance Considerations

For large installations, butterfly valves are often considered cost-effective because their lighter design requires less structural support and they typically need less maintenance over time. Replacing seals or liners is straightforward and does not usually require dismantling large sections of the pipeline. Double union ball valves also support easy maintenance but in a different context: their unions allow them to be detached without disturbing surrounding pipework, which is highly valued in laboratory or residential plumbing systems.

Role in HVAC and Building Services

Heating, ventilation, and air conditioning systems benefit from butterfly valves due to their ability to regulate chilled water or hot water flow across extensive networks. Their responsiveness to partial opening and closing positions ensures steady temperature control within buildings. In contrast, double union ball valves are often used in specific branches of these systems where modular replacement or system isolation is required.

Therefore, butterfly valves are effectively used in systems with large scale, large capacity and continuous regulation, while double union ball valves are suitable for areas where modularity and easy disassembly are crucial.The use of both within a single installation often reflects the complementary roles they play, ensuring that pipelines operate efficiently and can be maintained with less interference.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US