Across industrial and commercial piping networks, engineers often weigh the advantages of a butterfly valve against other options such as a double union ball valve. Each valve type has its own function in fluid control, but butterfly valves are frequently chosen when cost efficiency and long-term usability are important considerations. Their design allows them to serve a wide variety of applications.

Structural Efficiency and Material Use

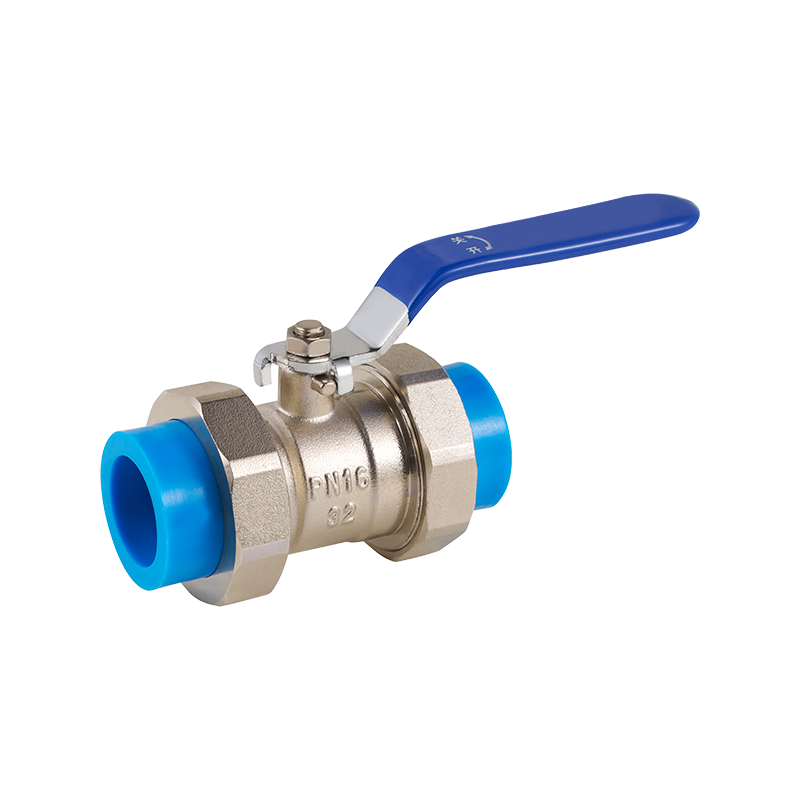

One of the reasons butterfly valves are regarded as cost-effective lies in their compact structure. Unlike bulkier valves, they require less material to manufacture while still providing dependable flow control. This not only lowers production costs but also reduces the overall weight of the valve, which simplifies transportation and installation. A double union ball valve, while convenient for quick removal and maintenance in smaller systems, generally involves more material per unit of flow capacity, making butterfly valves more practical in large-diameter pipelines.

Reduced Space Requirements

Space constraints are a common issue in industrial environments. Butterfly valves address this by requiring less clearance for operation since their disc rotates on a central shaft. This allows them to be installed in tighter spaces without compromising accessibility. In comparison, ball valves, even with union connections, often need more space for full rotation during operation or removal. By saving space, butterfly valves also reduce the need for extensive support structures, further lowering installation costs.

Versatility Across Applications

Butterfly valves are suitable for both on-off service and throttling applications, which means a single valve design can serve multiple purposes in the same system. From water treatment plants and power generation to HVAC systems, their adaptability reduces the need for purchasing different valve types for separate functions. Double union ball valves, while highly effective for shutoff tasks, are less commonly used for throttling. This flexibility gives butterfly valves an added advantage in systems that demand frequent flow adjustments.

Ease of Maintenance

Maintenance considerations often influence the overall cost of a piping system. Butterfly valves are designed with fewer moving parts, which simplifies inspection and replacement of components such as seals or liners. Servicing can often be performed without dismantling large sections of pipework, reducing downtime and labor costs. Double union ball valves also support convenient maintenance through their detachable design, but they are generally applied in smaller-scale systems where quick disassembly is the primary benefit. For large-volume operations, the butterfly valve’s straightforward maintenance process contributes significantly to its cost-effectiveness.

Energy Efficiency Through Lower Pressure Drop

When fully open, the butterfly valve allows fluid to pass with less obstruction, thereby reducing pressure loss within the system. This feature means that pumps require less energy to maintain the desired flow rate, which translates into lower operational costs over time. In extensive networks, such as municipal water systems or cooling plants, even small reductions in energy demand can add up to substantial savings. While double union ball valves also offer relatively smooth flow, they are typically employed in smaller applications where energy savings are less pronounced.

Broad Range of Material and Size Options

Butterfly valves are produced in a wide variety of sizes, from small diameters suitable for localized systems to very large valves capable of handling municipal or industrial pipelines. They are also manufactured in different body and seal materials to match specific media, including water, air, and corrosive chemicals. This adaptability ensures that a single valve type can cover a broad range of requirements, reducing the need for stocking multiple valve categories. Double union ball valves serve a different role, primarily supporting systems that prioritize modular replacement, often in smaller or specialized pipelines.

Compatibility with Automation

Modern facilities frequently depend on automated systems for regulating fluid flow. Butterfly valves are well-suited for integration with electric, pneumatic, or hydraulic actuators due to their light weight and simple design. This reduces the cost of actuation equipment and simplifies system integration. For industries moving toward centralized or remote-controlled operations, this feature adds long-term value without driving up initial costs. Double union ball valves can also be automated but are generally more limited in scale and application.

Butterfly valves bring together practical design, energy efficiency, and ease of maintenance, making them a cost-effective option for many large-scale and continuously operating systems. When used alongside double union ball valves in installations that require both high-volume flow control and modular isolation points, they contribute to building flexible and economical piping networks that meet diverse operational needs.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US