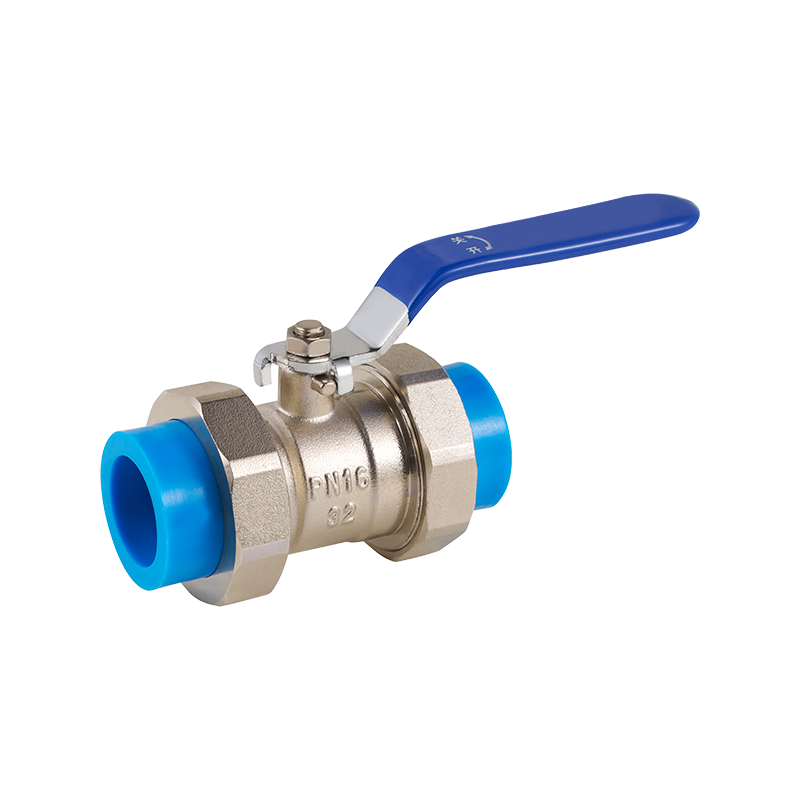

Across many piping systems, both the butterfly valve and the double union ball valve are frequently applied for fluid control, but their roles differ depending on operational needs. For operators and engineers seeking convenience in installation and maintenance, the double union ball valve stands out as a practical choice. Its structure allows quick disassembly without disturbing the rest of the system, which is particularly valuable in applications that demand frequent servicing or where pipelines are tightly arranged.

Modular Design for Quick Replacement

The double union ball valve is designed with unions on both ends, which enables the valve body to be detached easily from the pipeline. This modular design is especially useful in systems that require regular cleaning or inspection, such as water filtration units, laboratory setups, or chemical dosing equipment. By loosening the unions, the valve can be removed without cutting pipes or shutting down the entire line. This reduces downtime and labor requirements, contributing to smoother operation of the overall system.

Installation Flexibility in Confined Spaces

Space is often limited in modern piping installations, whether in residential systems, industrial plants, or agricultural setups. The compact structure of a double union ball valve makes it easier to install in narrow spaces where a butterfly valve or other larger valve types may not be practical. The ability to align and tighten unions without needing additional clearance simplifies installation, particularly for technicians working in environments where accessibility is restricted.

Effective Flow Control for Smaller Systems

While butterfly valves are more commonly used for large-diameter pipelines and flow regulation, double union ball valves are well-suited for small to medium-sized applications. They provide reliable on-off control, ensuring that fluids can be quickly isolated when needed. This makes them a practical option in domestic water systems, irrigation setups, or smaller industrial processes where precision throttling is less critical but dependable shutoff is essential.

Maintenance Without Pipeline Disruption

Operators can disassemble the valve for inspection, seal replacement, or cleaning without disturbing adjacent piping. This is particularly useful in systems handling chemicals or fluids that require frequent valve maintenance. By reducing disruptions, technicians can maintain efficiency and avoid unnecessary downtime. Compared to butterfly valves, which often require the entire valve to be integrated into a larger pipe section, the double union design provides more direct maintenance access in compact systems.

Material Options for Different Applications

Double union ball valves are available in a variety of materials, including PVC, brass, and stainless steel, each suited to different types of media. For example, PVC versions are widely used in swimming pool systems and aquariums due to their corrosion resistance, while metal options are better suited for higher pressure or temperature conditions. Similarly, butterfly valves are produced in materials ranging from cast iron to stainless steel, making them adaptable for large industrial pipelines. The choice between the two depends largely on system size and service conditions.

Cost and Operational Considerations

From an economic perspective, double union ball valves can reduce maintenance expenses by eliminating the need for specialized tools or extensive downtime during servicing. For smaller-scale applications, they also offer an affordable option that balances durability with convenience. Butterfly valves, while often more cost-effective for larger installations, may not provide the same ease of removal in compact systems. This makes the double union ball valve a better fit where frequent inspection is expected.

Integration With Automation Systems

Although typically used in manual applications, double union ball valves can also be equipped with actuators for automated control in certain setups. This flexibility extends their use beyond basic plumbing into more advanced fluid management systems. Butterfly valves, on the other hand, are more widely automated in large industrial facilities due to their suitability for regulating continuous flow. The coexistence of both valve types within a single network allows engineers to balance large-scale flow regulation with smaller-scale isolation needs.

Double union ball valves simplify maintenance and installation by offering modularity, compact design, and practical functionality for smaller systems. When combined with butterfly valves in larger pipeline networks, they contribute to building flexible systems where efficient operation and ease of servicing are both achieved.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US