Across fluid management systems, the butterfly valve and the double union ball valve are often considered for different purposes. Both provide practical solutions in piping networks, but butterfly valves are particularly recognized for their ability to improve system efficiency while maintaining precise control over flow. Their compact design, adaptability, and performance characteristics make them useful in industries where balancing energy use, maintenance, and operational control is important.

Streamlined Structure for Energy Savings

Butterfly valves operate using a disc that rotates around a central axis. When fully open, the disc aligns closely with the direction of fluid flow. Lower pressure drop means that pumps do not have to work as hard to maintain flow rates, which directly decreases energy consumption across large networks. In applications such as municipal water systems or HVAC installations, this energy-saving feature becomes an important factor in long-term operational efficiency. By contrast, a double union ball valve, though effective for smaller systems, does not provide the same level of flow efficiency in large-scale networks.

Versatility in Flow Control

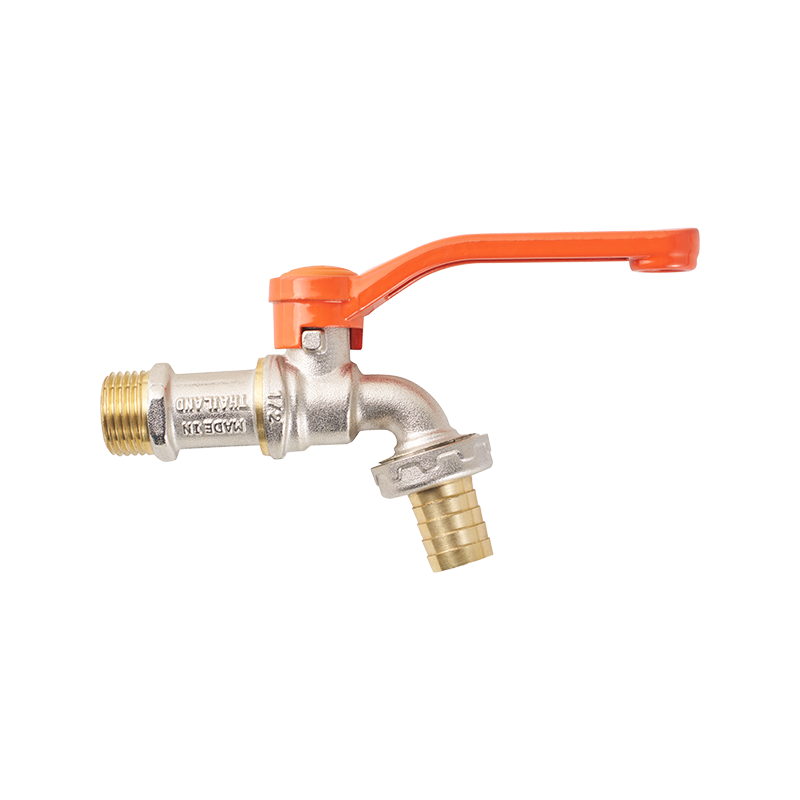

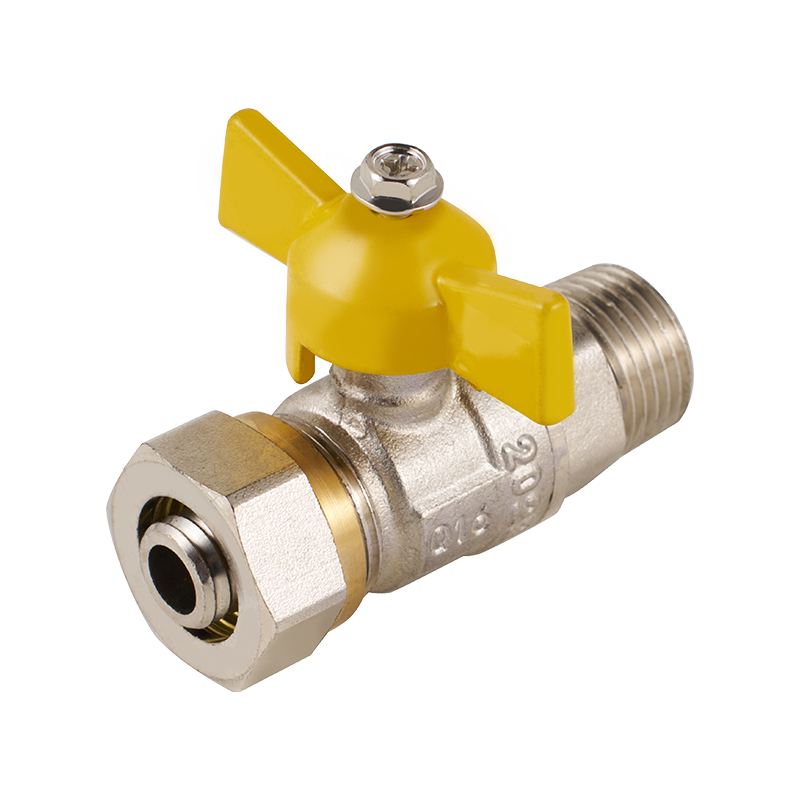

Butterfly valves are designed to handle both on-off service and throttling functions. The disc can be positioned at various angles, allowing for incremental flow adjustments. This level of control is valuable in industries such as chemical processing, food production, and power generation, where system balance depends on regulating flow with precision. Double union ball valves, on the other hand, are generally favored in situations requiring full shutoff and easy removal rather than continuous regulation.

Application in Large-Scale Pipelines

Because butterfly valves are available in a wide range of sizes, they are often the preferred choice for large-diameter pipelines. Their lightweight construction relative to their size makes installation more practical compared to other valve types. This is why they are commonly used in water distribution networks, marine systems, and industrial cooling lines. In contrast, double union ball valves are more suitable for smaller pipelines, particularly where maintenance access is frequently needed.

Maintenance and Service Benefits

Maintenance efficiency plays a critical role in system design. Butterfly valves, with their simple structure, are generally straightforward to inspect and service. Replacement of seats or seals can often be completed without removing the entire valve from the line. This reduces downtime, which is especially beneficial in continuous operation environments. While double union ball valves also provide easy maintenance through detachable unions, their advantage is mainly in smaller systems where the valve itself needs to be removed for cleaning or inspection.

Adaptability to Various Media

Butterfly valves are constructed in a variety of materials, making them adaptable to different fluids including water, air, oils, and certain chemicals. The choice of liner and sealing materials allows them to function effectively even in corrosive or abrasive environments. Double union ball valves also offer flexibility in material choices, such as PVC for pool and irrigation systems or brass for plumbing applications, but they are generally applied in more specialized or limited-scale installations.

Compatibility With Automation

The growing use of automated systems in industrial operations has made actuator compatibility a critical feature for valves. Butterfly valves integrate smoothly with electric, pneumatic, or hydraulic actuators due to their light operating torque. This allows for remote or centralized control, which is valuable in large facilities where manual operation is not practical. Double union ball valves can also be automated, though they are less frequently used in such applications because they are usually reserved for modular, manually controlled systems.

Balancing Roles Within a System

In many fluid networks, butterfly valves and double union ball valves are not competitors but complementary components. Butterfly valves manage larger flows and provide efficient throttling, while double union ball valves are installed in smaller sections where modularity and quick replacement are important. By combining both types, system designers achieve a balance between efficiency, control, and maintenance convenience.

Butterfly valves contribute to system efficiency by reducing energy loss, simplifying maintenance, and offering versatile flow control. When applied alongside double union ball valves in areas that require modular access, they form part of a flexible and effective piping strategy that addresses both large-scale performance and localized service needs.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US