Flow control is a critical aspect of many plumbing and industrial systems. Achieving smooth and reliable regulation of water or fluid movement can prevent damage, improve system efficiency, and extend equipment lifespan. One of the essential components that help maintain this balance is the precision valve. Precision valves come in many forms and serve various purposes, but three particular types—the inline water pressure reducing valve, the 3 inch check valve, and the ball valve outside tap—play significant roles in ensuring effective flow control.

The inline water pressure reducing valve is designed to manage water pressure within a system, keeping it at a consistent and safe level. This valve is typically installed directly within the water line and helps to prevent sudden pressure spikes that could otherwise cause leaks or damage to pipes and fittings. By regulating pressure, the inline water pressure reducing valve enhances system safety and prevents costly repairs. In residential and commercial settings, this valve is often used to protect plumbing fixtures and appliances from high pressure that could shorten their useful life.

Another valve that contributes to flow control is the 3 inch check valve. Its main function is to allow fluid to flow in one direction while preventing backflow. This simple but effective mechanism is vital in applications where reverse flow could cause contamination or disrupt the operation of pumps and other equipment. The 3 inch check valve is common in water supply systems, wastewater treatment plants, and heating systems. Its size, which is suitable for moderate to large pipe diameters, allows it to handle significant volumes while maintaining reliability.

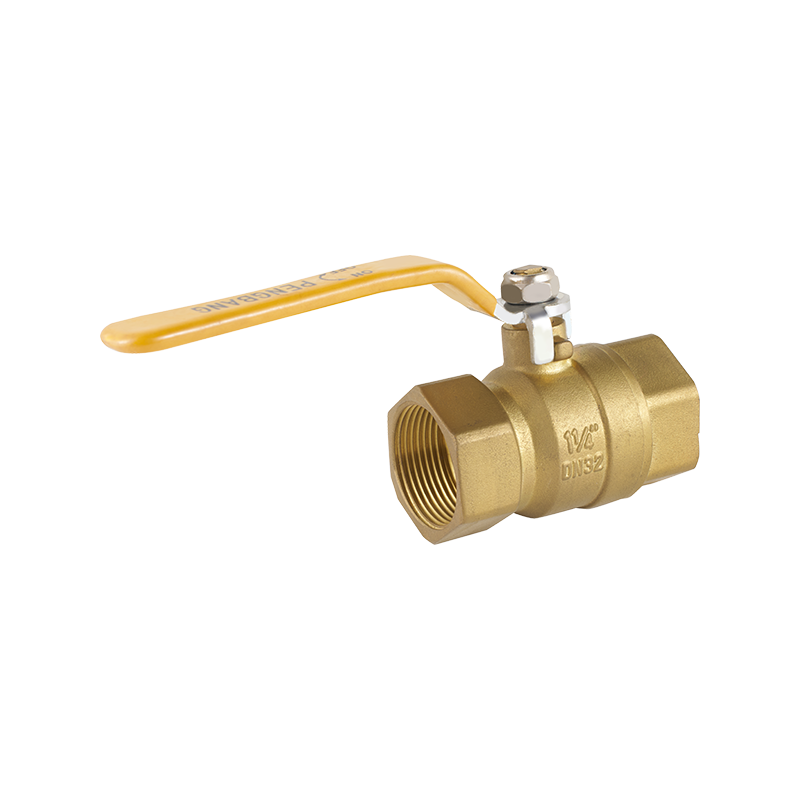

The ball valve outside tap serves a dual purpose of controlling flow and providing access to water outside a building or system. This valve type is easy to operate, offering quick shut-off capabilities with a simple quarter-turn motion. It is often found in garden irrigation, outdoor cleaning stations, and other external water access points. The ball valve outside tap's straightforward design allows for dependable flow control, making it a practical choice for outdoor water management.

Integrating these three valves—inline water pressure reducing valve, 3 inch check valve, and ball valve outside tap—into a system allows for a layered approach to flow control. Each valve addresses a specific challenge: managing pressure, preventing backflow, and offering accessible shut-off points. When used together, they create a comprehensive solution that enhances system performance.

One of the key benefits of using an inline water pressure reducing valve is the ability to protect downstream components from pressure fluctuations. Without this valve, sudden changes in pressure could advance to pipe bursts or damage to sensitive equipment. Installing this valve within a water supply line allows the system to maintain a steady pressure, improving overall durability.

Similarly, the 3 inch check valve plays a crucial role in preventing reverse flow, which can be problematic in many setups. For example, in a pump system, backflow could cause pump damage or contamination of clean water supplies. By installing a 3 inch check valve, the system can ensure that water only moves in the intended direction, improving operational safety.

The ball valve outside tap adds convenience and control for external water use. Its user-friendly design means that even those with little technical knowledge can easily open or close the water supply. This valve's reliable sealing helps avoid leaks and water waste, which is especially important in outdoor environments where uncontrolled flow could advance to flooding or damage.

Regular maintenance and proper selection of these valves are essential to achieving reliable flow control. The inline water pressure reducing valve should be inspected periodically to ensure that it is regulating pressure as intended. Similarly, the 3 inch check valve must be checked for wear or debris that could impair its ability to prevent backflow. The ball valve outside tap, being exposed to external elements, requires attention to prevent corrosion and ensure smooth operation.

In summary, improving flow control with precision valves involves understanding the roles and benefits of different valve types. The inline water pressure reducing valve helps maintain consistent pressure, reducing strain on the system. The 3 inch check valve ensures fluid moves in the correct direction, protecting against backflow issues. The ball valve outside tap provides easy and reliable access to outdoor water supplies with effective shut-off capability. Together, these valves contribute to safer, more efficient, and manageable fluid systems.

By carefully integrating an inline water pressure reducing valve, a 3 inch check valve, and a ball valve outside tap into a plumbing or industrial system, operators can experience improved control and reduced risk of damage or failure. Their combined presence enhances the ability to maintain desired flow conditions, making system management more straightforward and less prone to unexpected problems. As flow control continues to be a focus for system reliability, the use of these precision valves remains a practical approach to meeting diverse operational needs.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US