The PVC pressure reducing valve is designed to automatically maintain a constant downstream pressure regardless of fluctuations in upstream pressure. In industrial settings, this type of valve helps protect downstream equipment and piping from potential damage caused by excessive pressure. The integration of automation technologies in these valves has improved their responsiveness and reliability, making them indispensable in many control systems. Automated PVC pressure reducing valves can adjust quickly to changes, providing a steady pressure that supports consistent system performance.

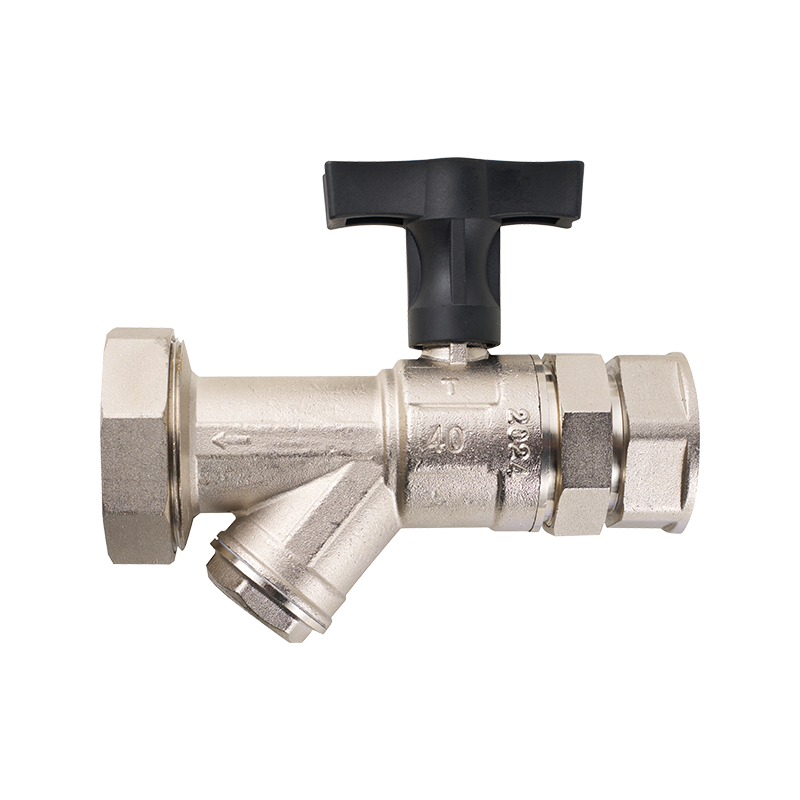

Another key component in industrial fluid control is the universal check valve. This valve permits fluid flow in one direction while preventing backflow, which is critical for maintaining system integrity and preventing contamination or damage. Advances in valve automation have enhanced the capabilities of universal check valves by enabling remote monitoring and control. Automated versions of these valves reduce the need for manual intervention, helping to avoid operational downtime and reduce maintenance costs. The ability to automatically respond to system changes makes the universal check valve an important part of many automated industrial setups.

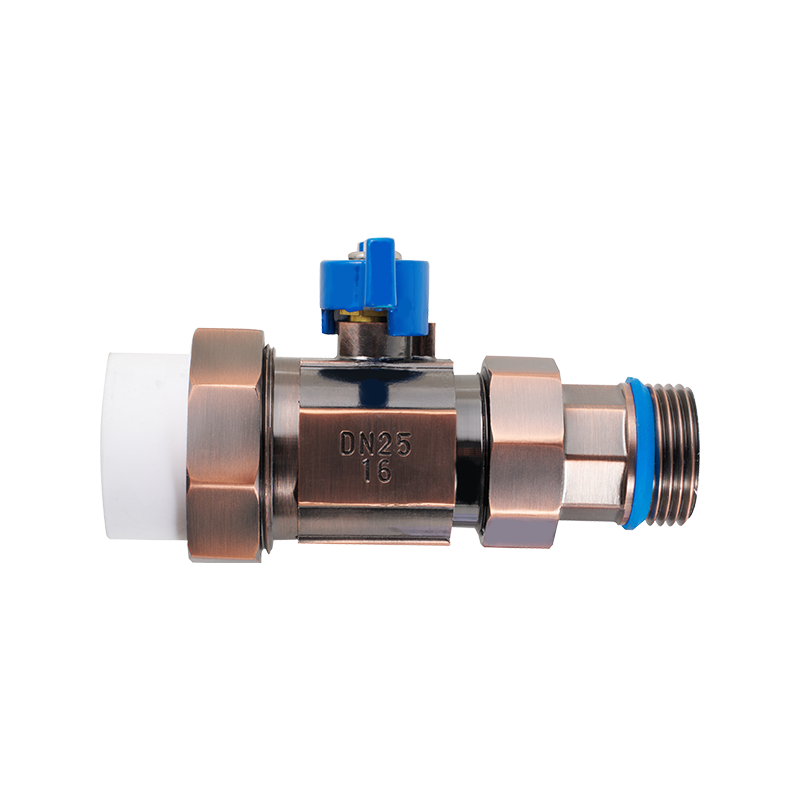

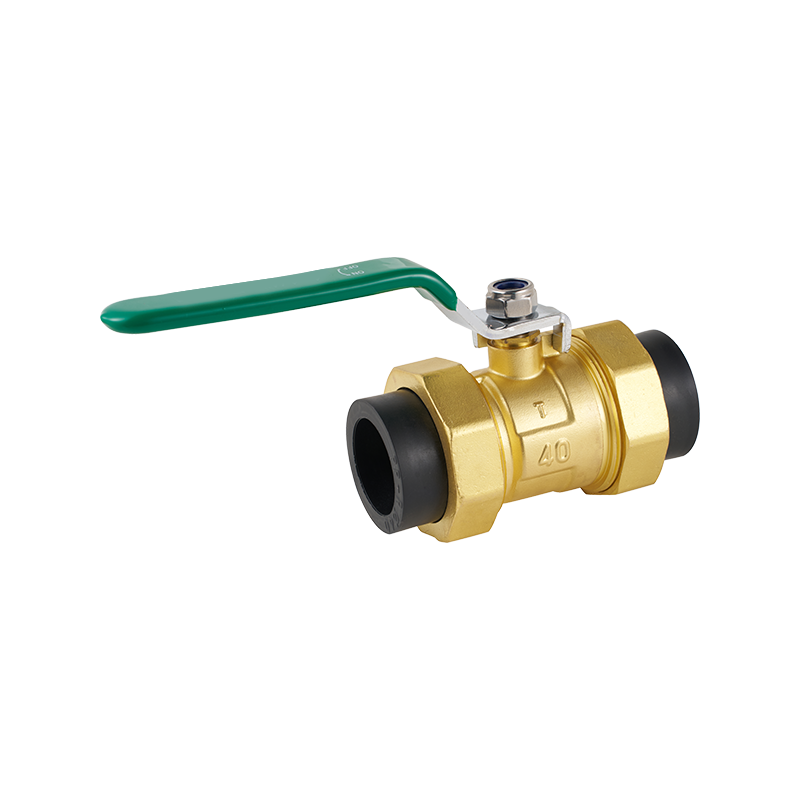

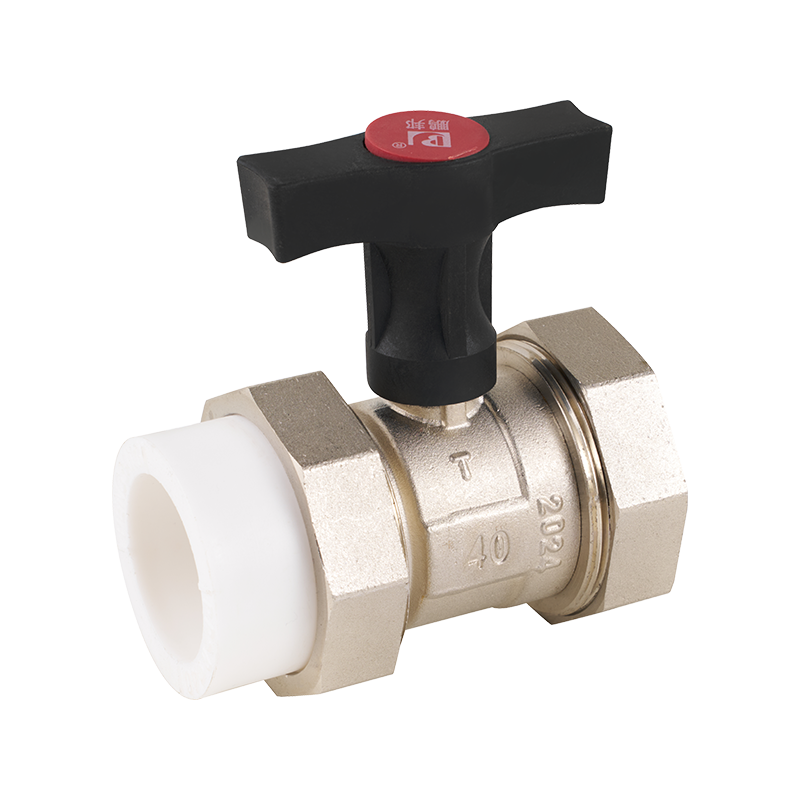

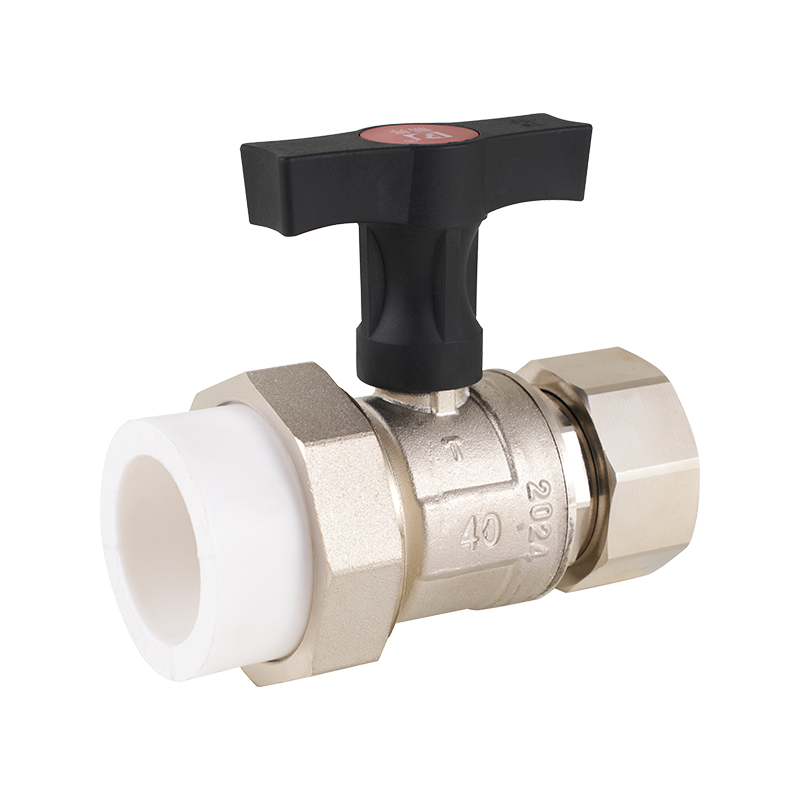

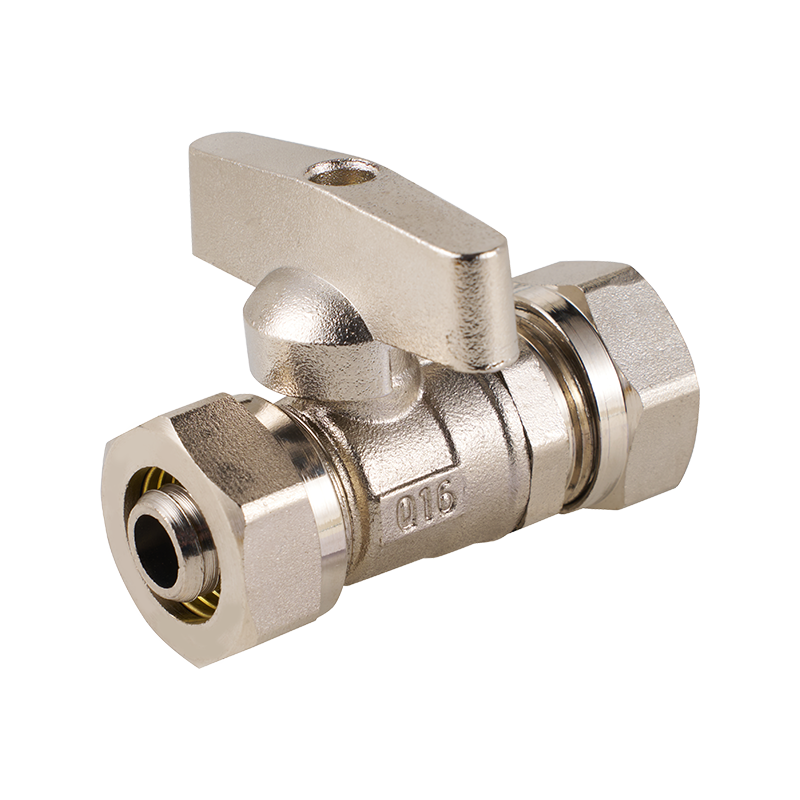

The ball valve for outdoor faucet is often overlooked in discussions about industrial valve automation, but it plays an important role in controlling water flow in external environments. These valves are designed to withstand weather conditions and are used in irrigation, landscaping, and outdoor water management systems. Automation of the ball valve for outdoor faucet allows for remote operation, which is particularly useful in large-scale or hard-to-reach installations. Automated ball valves can be integrated into broader control systems, enabling timed or sensor-based operation to conserve water and enhance system efficiency.

One significant advance in valve automation is the integration of smart sensors and actuators. These components enable valves such as the PVC pressure reducing valve, universal check valve, and ball valve for outdoor faucet to communicate with control systems in real time. This communication allows for better system diagnostics, predictive maintenance, and rapid adjustments based on actual operating conditions. As a result, operators gain greater control and visibility over fluid management processes, reducing the likelihood of failures or inefficiencies.

In industrial applications, the durability and material compatibility of automated valves are vital. For instance, the PVC pressure reducing valve is valued for its corrosion resistance and suitability in handling chemicals and potable water. Automated versions maintain these material advantages while adding precise control features. Similarly, the universal check valve is designed with materials that support various fluid types and pressures, ensuring reliable operation even under demanding conditions. The ball valve for outdoor faucet combines robust materials with automation to endure external environmental factors while providing convenient flow control.

Automation also helps address safety concerns in industrial fluid systems. Automated PVC pressure reducing valves can quickly respond to pressure spikes, preventing potential bursts or leaks. Automated universal check valves safeguard against backflow that could contaminate clean water supplies or damage equipment. Meanwhile, automated ball valves for outdoor faucets allow operators to shut off water remotely in emergencies, resulting in less damage and water loss. These safety benefits contribute to the overall reliability and security of industrial control systems.

The use of automation in valves is also connected to energy and resource efficiency. By precisely controlling flow and pressure, automated PVC pressure reducing valves reduce unnecessary energy consumption in pumping systems. Automated universal check valves prevent unwanted backflow that could advance to wasted energy or resources. Additionally, automated ball valves for outdoor faucets enable controlled irrigation schedules that conserve water. Such efficiencies align well with growing industrial demands for sustainability and cost-effectiveness.

As industrial control systems evolve, the trend toward integration of valve automation with digital platforms continues to grow. The PVC pressure reducing valve, universal check valve, and ball valve for outdoor faucet are all increasingly designed to interface with control software and networks. This integration facilitates centralized monitoring, remote troubleshooting, and coordinated control strategies. Consequently, these valves are not just standalone components but key parts of a larger ecosystem aimed at enhancing operational effectiveness.

In conclusion, advances in valve automation have brought notable improvements to industrial fluid control. The PVC pressure reducing valve, universal check valve, and ball valve for outdoor faucet illustrate how automation contributes to enhanced performance, safety, and efficiency. Through better materials, smart sensors, and network integration, these valves support the demands of modern industrial environments. As technology continues to develop, valve automation will likely play an even greater role in shaping the future of industrial control systems.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US