When it comes to valve components, choosing the right materials is a critical step toward ensuring durability and reliable performance over time. Valves like the residential pressure reducing valve, three way check valve, and ball valve kitchen faucet are all essential in various plumbing and heating systems, and their longevity often depends heavily on the materials used in their construction.

The residential pressure reducing valve plays a key role in controlling water pressure in home plumbing systems. Because it operates under varying pressure levels, the material of its components must withstand not only water flow but also pressure fluctuations without degrading. Typically, brass and stainless steel are common choices due to their resistance to corrosion and mechanical strength. Brass is widely used for residential pressure reducing valves because it balances durability with cost-effectiveness, while stainless steel offers enhanced resistance to corrosion, making it suitable for harsher water conditions. Selecting the right material for these valves reduces maintenance needs and extends the service life, which is especially important for residential systems where access can sometimes be limited.

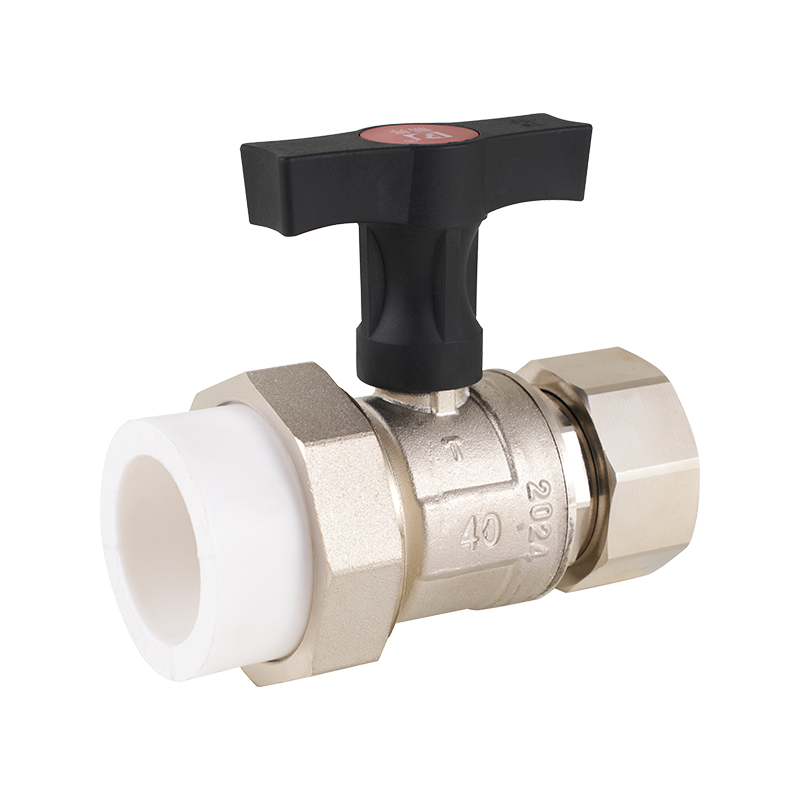

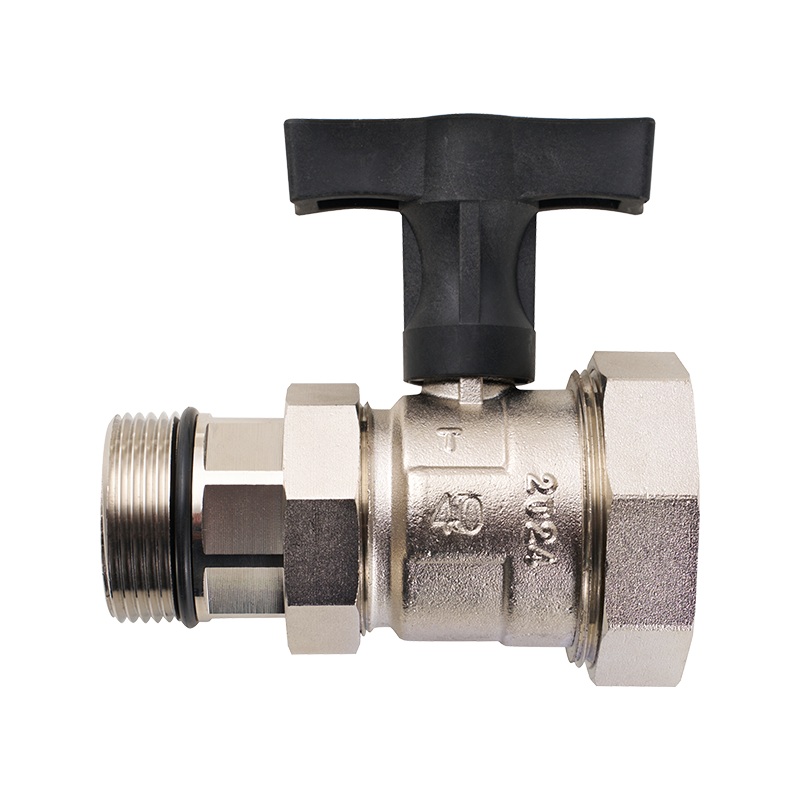

Similarly, the three way check valve requires careful material selection. This valve type allows fluid to flow in multiple directions while preventing backflow, which is crucial in many industrial and residential applications. The internal components of a three way check valve are subject to continuous movement and pressure changes, so materials must provide both strength and flexibility. Polymers like PTFE (Teflon) are often used for the sealing parts because of their chemical resistance and low friction properties, while the valve body itself is commonly made of bronze, brass, or stainless steel, depending on the application environment. Choosing materials that suit the specific fluid type and pressure conditions can prevent premature wear and failure in these valves.

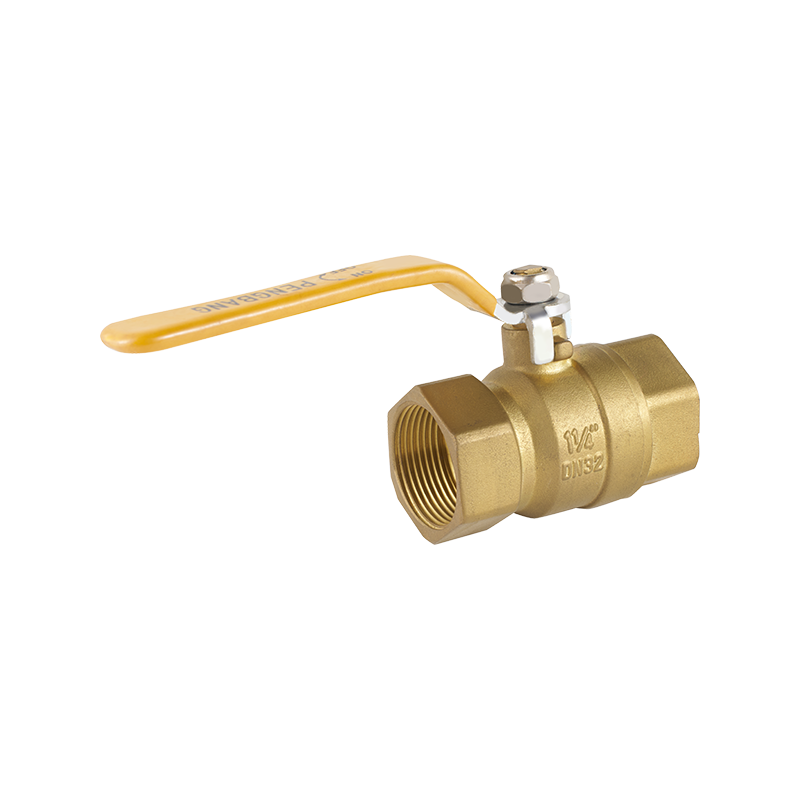

The ball valve kitchen faucet is another widely used valve, where material selection directly affects both functionality and aesthetics. Since this valve is often in contact with potable water and used frequently, the materials must be safe, corrosion-resistant, and durable under repeated mechanical action. Stainless steel and brass are popular choices for ball valve kitchen faucets due to their ability to resist corrosion from water and cleaning agents. In addition to the metal components, seals made from rubber or synthetic materials must be selected to avoid leaks and maintain smooth operation. Material choices in ball valve kitchen faucets influence how well the valve performs in daily use and how long it will last without needing repairs.

In residential pressure reducing valves, the interaction between water quality and valve material is also an important consideration. Hard water with high mineral content can accelerate corrosion or cause scaling inside the valve, which can affect performance. Materials such as stainless steel or specially coated brass can help reduce these issues, allowing residential pressure reducing valves to maintain consistent pressure regulation over time. Proper material choice helps avoid frequent replacements and system interruptions.

For the three way check valve, its application can vary from heating systems to irrigation setups, which means it may face different environmental challenges such as temperature bands or exposure to chemicals. Selecting materials that are compatible with these conditions is necessary to prevent valve malfunction. For example, PTFE seals are chosen for their ability to maintain sealing integrity even in aggressive chemical environments. The valve body materials, like bronze or stainless steel offer structural support and corrosion resistance, providing a balance that suits a wide range of uses.

Ball valve kitchen faucets, due to their frequent manual operation, benefit from materials that resist wear from repetitive motion. The ball inside the valve must be smooth and durable, often made from chrome-plated brass or stainless steel to lessen friction and resist corrosion. The housing needs to withstand water pressure and daily use without deformation. The seals, usually made from materials like EPDM or silicone, must maintain elasticity over many cycles of opening and closing. Careful selection of these materials can advance to a ball valve kitchen faucet that remains reliable and leak-free for years.

Material science advances have introduced several alternatives to traditional metals and polymers in valve manufacturing. Composite materials and advanced plastics are becoming more common in certain valve parts, offering lightweight options with good corrosion resistance. However, for critical components like those in residential pressure reducing valves, three way check valves, and ball valve kitchen faucets, tried-and-true materials such as brass, stainless steel, and PTFE still hold strong because of their proven track records.

In conclusion, the lifespan and performance of valves like the residential pressure reducing valve, three way check valve, and ball valve kitchen faucet are closely linked to material selection. Choosing materials that suit the application environment, handle pressure and temperature variations, and resist corrosion and wear will contribute to longer-lasting valve components. Thoughtful material choice reduces maintenance requirements and supports system reliability, which is valuable for both residential and commercial plumbing applications.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US