Pipe fitting materials play a crucial role in the performance and durability of any piping system. Choosing the right material is essential not only for ensuring compatibility with the fluids or gases being transported but also for maintaining system safety and efficiency over time. This article explores various pipe fitting materials and their compatibility with different applications, highlighting important components like the industrial pressure reducing valve, and natural gas safety valve.

One of the lots of common pipe fitting materials is steel, particularly carbon steel and stainless steel. Carbon steel fittings are widely used in industrial applications due to their strength and affordability. However, they require proper corrosion protection when exposed to moisture or corrosive fluids. Stainless steel fittings offer better corrosion resistance, making them suitable for more demanding environments, such as those involving chemicals or high humidity. These materials are often paired with valves such as industrial pressure reducing valves, which help regulate fluid pressure within a system. Using compatible materials for both the fittings and valves ensures a reliable seal and reduces the risk of leaks or failures.

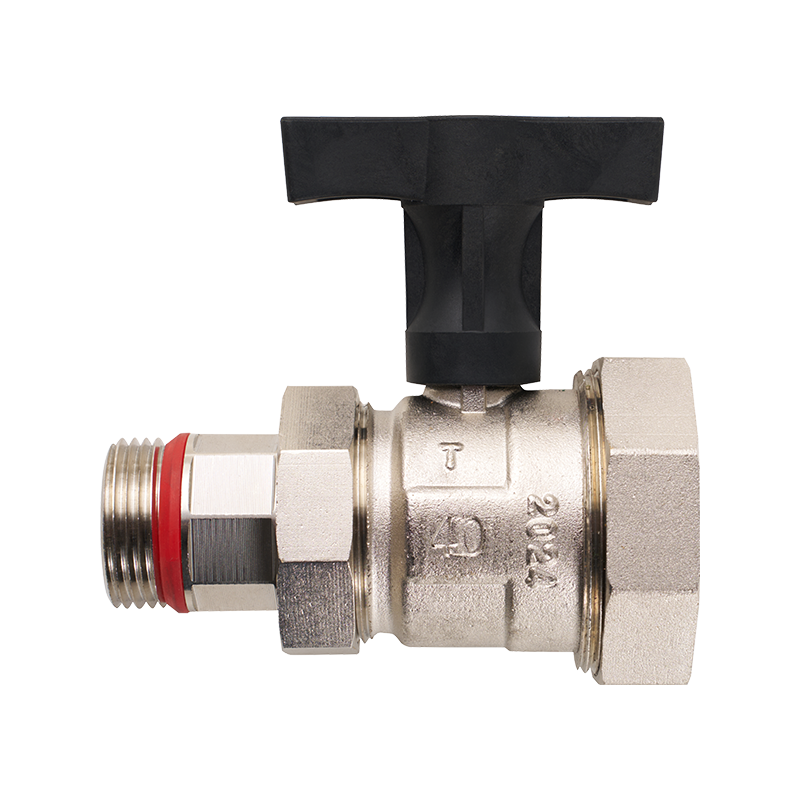

Copper is another frequently used material, especially in residential plumbing and HVAC systems. Copper fittings have reliable thermal conductivity and corrosion resistance, which makes them suitable for hot and cold water supply lines. Copper's natural resistance to bacteria growth also adds a layer of safety in potable water systems. However, copper fittings are not recommended for use with natural gas or certain industrial chemicals, as they can degrade over time when exposed to these substances. For applications involving natural gas, specialized components such as the natural gas safety valve are used to prevent dangerous leaks and ensure system integrity. In these cases, pipe fittings made from materials like black iron or galvanized steel are preferred due to their compatibility with gas and pressure requirements.

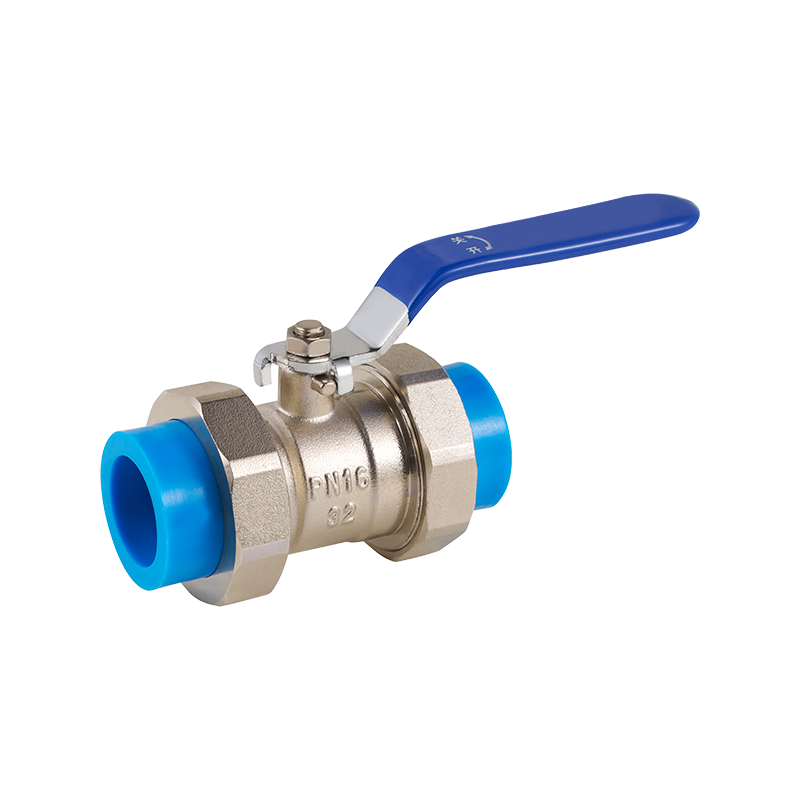

Plastic pipe fittings, including those made from PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), and PEX (cross-linked polyethylene), have gained popularity in recent decades. These materials offer corrosion resistance, flexibility, and ease of installation. PVC fittings are commonly used in drainage and cold water applications but are generally not suitable for high-temperature or high-pressure environments. CPVC extends PVC's temperature tolerance, making it a viable option for hot water lines. PEX fittings, often used in underfloor heating and potable water systems, provide flexibility and durability. When integrating valves such as the check valve, which prevents backflow, it's important to ensure that the valve materials and fittings are chemically compatible to avoid degradation or malfunction.

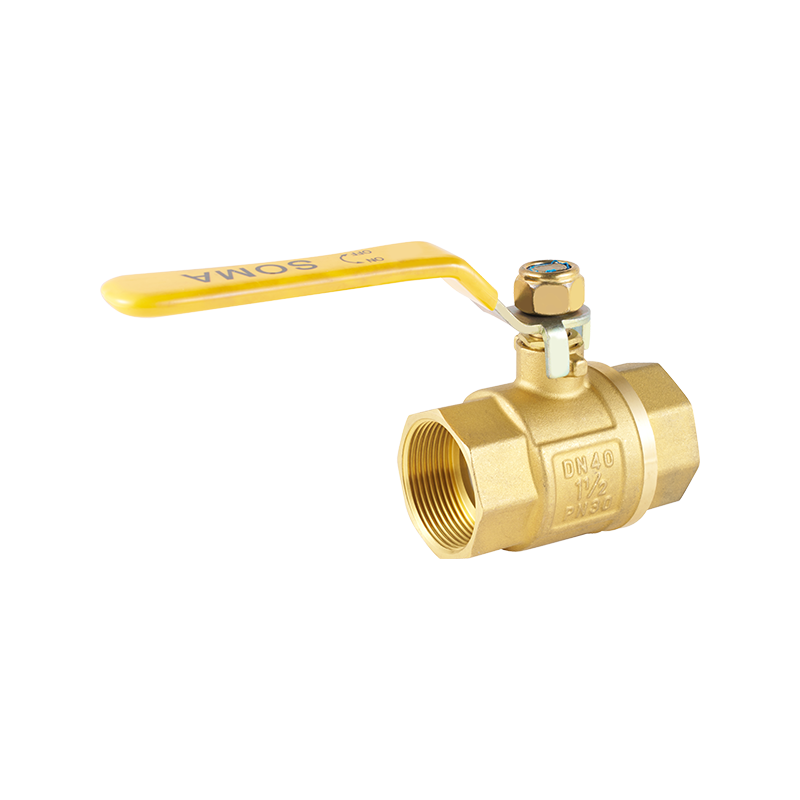

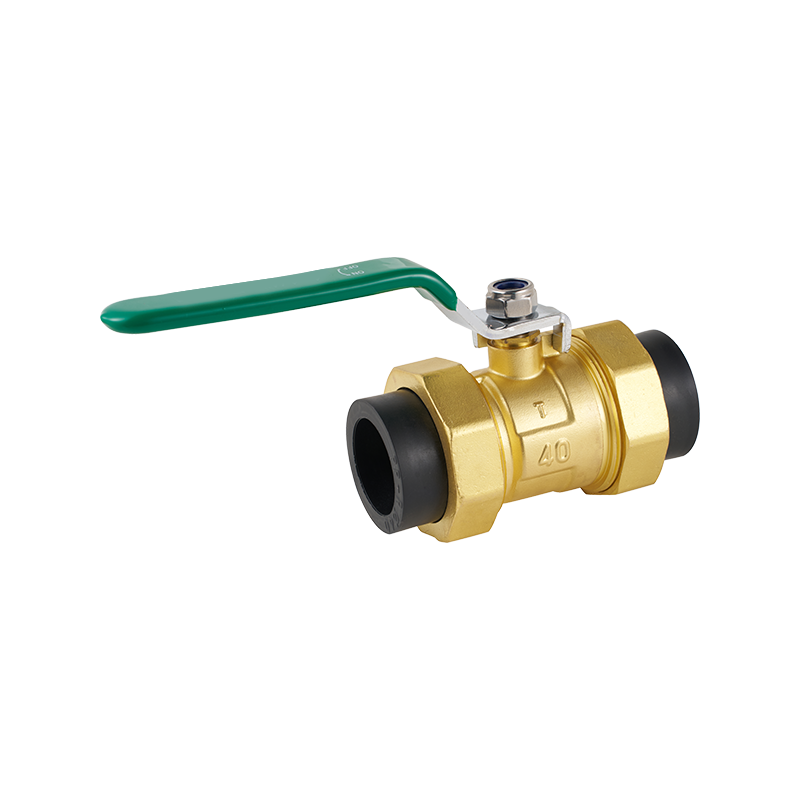

Brass fittings represent a middle ground between metals and plastics, combining good corrosion resistance with mechanical strength. Brass is widely used in plumbing systems, especially for smaller diameter pipes and fittings. Its compatibility with various fluids, including potable water and some chemicals, makes it a versatile choice. Brass fittings are often paired with valves like the industrial pressure reducing valve or the check valve, given their ability to withstand pressure variations and maintain a tight seal. Still, in highly corrosive environments or where bad temperatures occur, alternative materials might be necessary.

The compatibility of pipe fitting materials also depends on the fluid or gas temperature, pressure, and chemical composition. For example, natural gas systems require materials that can withstand specific pressure ranges and resist embrittlement over time. Using the right natural gas safety valve in combination with suitable pipe fittings is vital for ensuring safe operation. Likewise, systems transporting chemicals or steam require fittings made from materials resistant to corrosion and thermal stress.

It is important to consider joint types and sealing methods alongside material choice. Threaded fittings, welded joints, and solvent-welded connections each have their own compatibility requirements and performance characteristics. The sealing material, such as PTFE tape or gaskets, must also be compatible with both the fluid and the fitting material to prevent leaks and ensure longevity.

Maintenance and inspection practices also influence the overall system reliability. Even with compatible materials, improper installation or lack of regular checks can advance to issues such as leaks, corrosion, or valve failures. For example, a check valve installed in a system with incompatible fittings may suffer from premature wear, reducing its effectiveness in preventing backflow.

In conclusion, selecting appropriate pipe fitting materials is a balancing act that requires understanding the application's demands, the fluids or gases involved, and the operating conditions. Components like the check valve, industrial pressure reducing valve, and natural gas safety valve are integral parts of many systems and must be matched with compatible fittings to maintain safety and functionality. Taking the time to evaluate material properties and compatibility helps ensure that piping systems operate reliably over their service life.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US