In many piping and plumbing systems, maintaining system integrity is a key factor that affects performance, safety, and durability. One often overlooked component that contributes significantly to system stability is the threaded fitting. Threaded fittings, by virtue of their design and application, offer a reliable connection method that enhances the overall integrity of various fluid and gas systems. This article explores how threaded fittings contribute to system integrity and how they complement other important components such as the air flow check valve, adjustable PRV valve, and LPG ball valve.

Threaded fittings are mechanical connectors that join pipes or other fittings via screw threads, creating a tight seal that is often both durable and serviceable. One of the main advantages of threaded fittings is their ease of installation and disassembly. Unlike welded or flanged connections, threaded fittings do not require specialized equipment or procedures, allowing for quicker assembly and maintenance. This ease of use plays an important role in preserving system integrity over time, as repairs or adjustments can be made without extensive downtime or damage to surrounding components.

From a structural perspective, threaded fittings provide strong mechanical engagement between connected parts. The threads act like tiny ramps that convert rotational motion into axial force, pulling pipes together tightly. This tightness helps prevent leaks and withstand pressure fluctuations common in fluid transport systems. Proper thread engagement also resists vibration-induced loosening, which can be a common cause of failures in many industrial environments.

Another aspect where threaded fittings improve system integrity is their versatility across different system types. Whether it's a high-pressure LPG line using an LPG ball valve, a water distribution system incorporating an adjustable PRV valve, or an air control system fitted with an air flow check valve, threaded connections offer compatibility with a wide range of valves and accessories. This versatility makes it easier to build and maintain complex piping networks with varied functions.

For example, consider the integration of an air flow check valve in a pneumatic system. These valves are critical for preventing backflow and ensuring that air moves in the correct direction. When paired with threaded fittings, air flow check valves can be securely installed and easily replaced if needed. The threaded connection ensures that the valve remains sealed under pressure changes, with fewer risks of air leakage or system contamination. In turn, this contributes directly to the system's integrity by maintaining correct flow patterns and preventing damage from reverse flow.

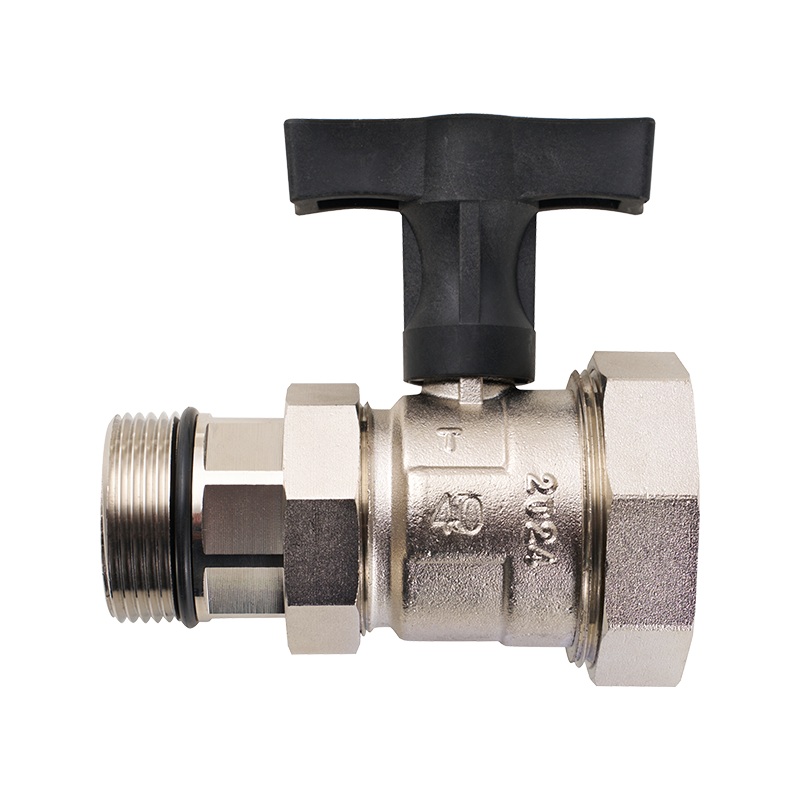

Similarly, adjustable PRV (Pressure Relief Valve) valves are often used to control and stabilize pressure within water or gas piping systems. These valves must be tightly sealed to prevent pressure loss and to protect downstream components. Threaded fittings offer a reliable interface to connect PRV valves into piping runs, allowing for secure attachment and ease of adjustment or replacement. Since pressure variations can put stress on joints, the secure mechanical lock provided by threading helps maintain consistent pressure control, reducing the chance of joint failure or leaks.

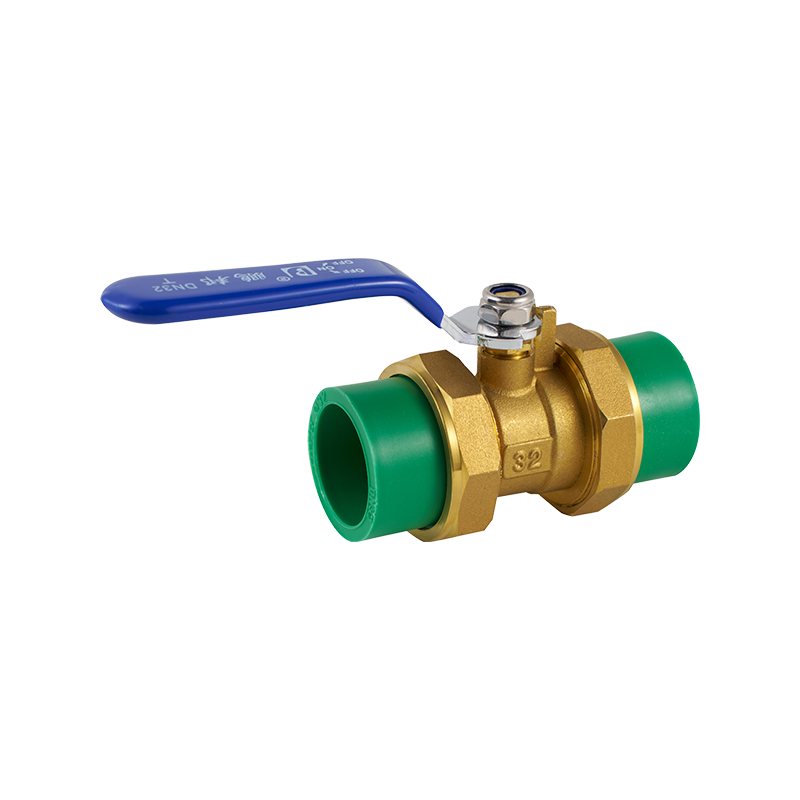

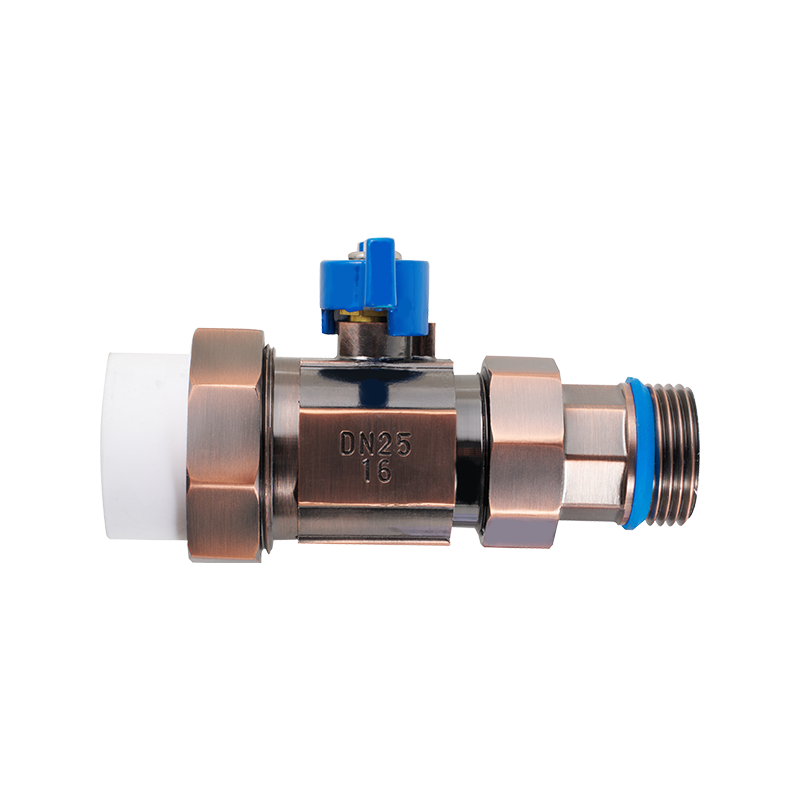

LPG ball valves also benefit significantly from threaded fittings. LPG systems require components that can safely handle flammable gases under pressure. Ball valves allow for rapid shutoff and control of LPG flow, making their secure installation crucial for safety and system performance. Threaded fittings provide the sturdy and leak-resistant connection needed in LPG applications, helping ensure that the ball valve functions correctly without risk of gas leakage. Moreover, when maintenance or replacement is necessary, the threaded connection allows technicians to remove the valve without cutting or welding pipes, which reduces the risk of accidental ignition during service.

It is important to note that while threaded fittings improve system integrity in many ways, proper installation is essential. Threads must be clean and undamaged, and appropriate sealing materials such as PTFE tape or pipe dope should be applied to prevent leaks. Over-tightening should be avoided to prevent thread stripping or cracking of fittings. When correctly installed and maintained, threaded fittings form a key part of a robust and safe piping system.

In conclusion, threaded fittings contribute to system integrity by providing secure, leak-resistant, and serviceable connections across a variety of piping applications. Their compatibility with components like air flow check valves, adjustable PRV valves, and LPG ball valves allows for flexible system design and reliable operation. By ensuring tight mechanical engagement and ease of maintenance, threaded fittings support the longevity and safety of fluid and gas transport systems without requiring complicated installation methods. This practical and dependable connection solution remains a valuable choice for many industrial and residential piping projects.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US