Water supply systems rely heavily on properly designed and installed pipe fittings to ensure safe, efficient, and reliable delivery of water. The standards governing pipe fittings in these systems are essential to maintain the integrity and functionality of the entire water infrastructure. Understanding these standards helps engineers, contractors, and maintenance personnel select and apply components that meet safety and performance requirements.

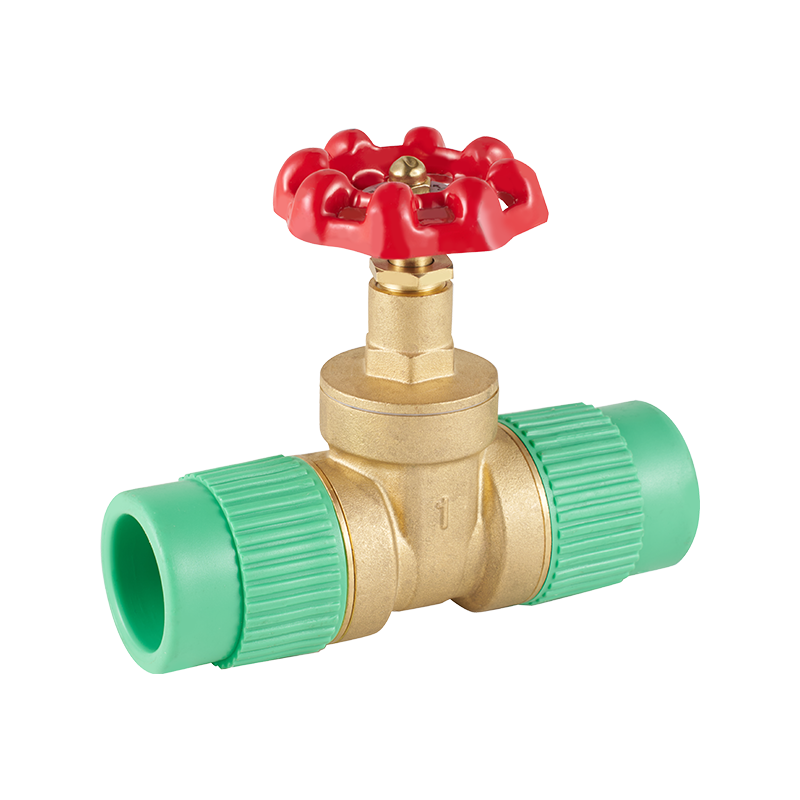

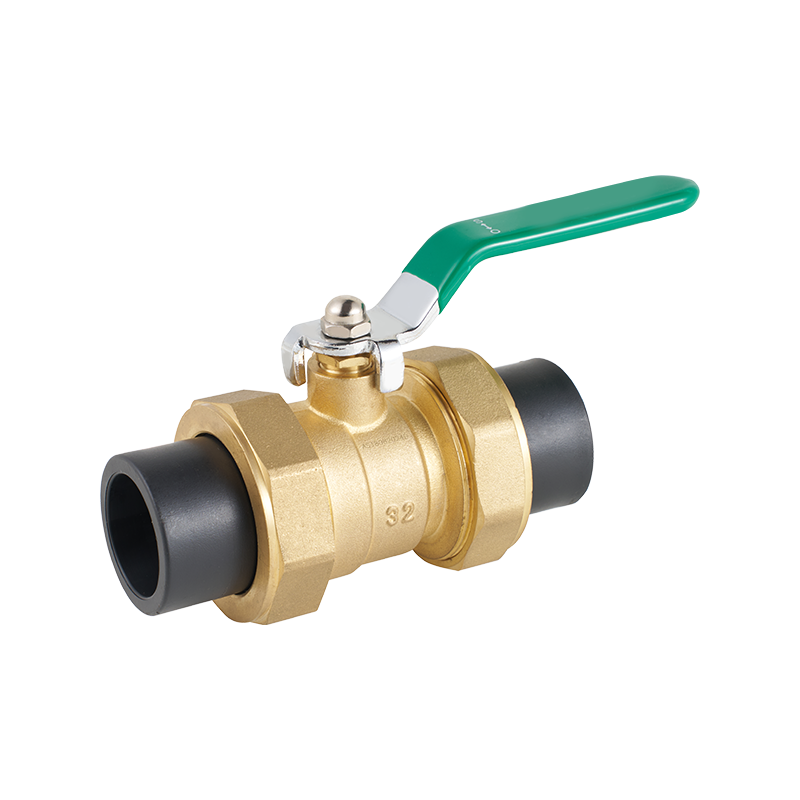

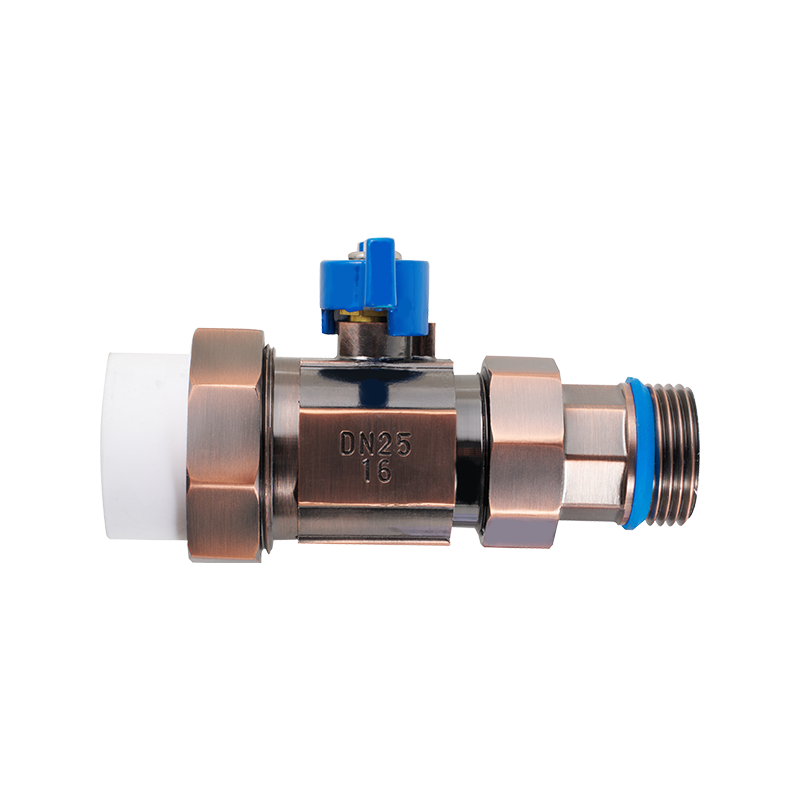

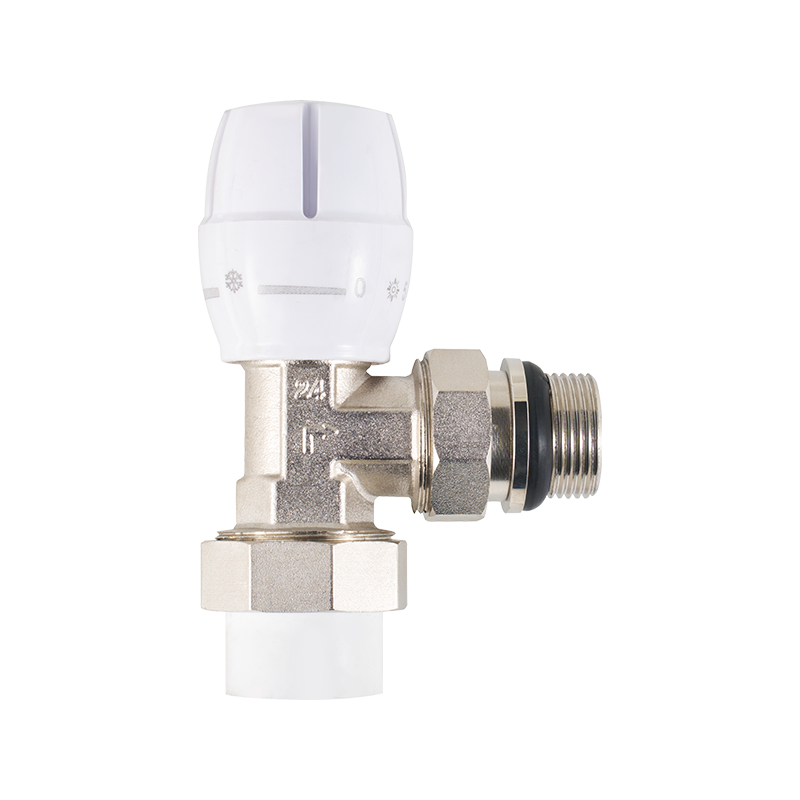

One of the fundamental aspects of pipe fitting standards is compatibility with the specific water system components. For example, a water spigot shut off valve plays a crucial role in controlling water flow in residential and commercial plumbing. This type of valve must conform to specific dimensions and pressure ratings to ensure it integrates smoothly with connecting pipes and other fittings. The standards outline the materials that can be used, the types of threads allowed, and the pressure limits under which the valve can operate safely.

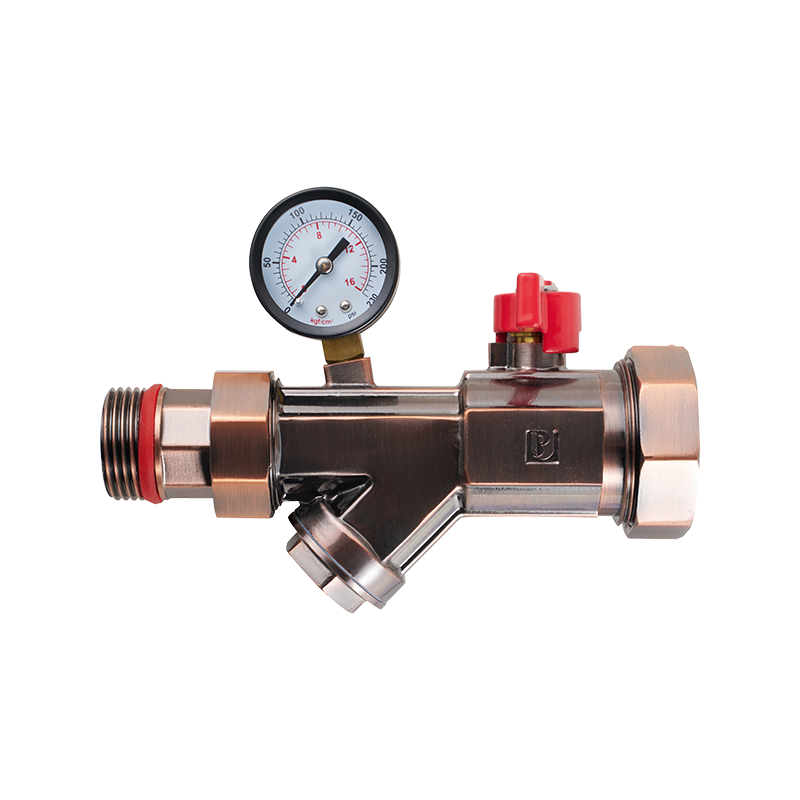

Material selection is another vital point in pipe fitting standards. Common materials include brass, stainless steel, copper, and various plastics, each suitable for different water quality and temperature conditions. Plastic fittings, especially those made from polypropylene or other polymers, often include components like the poly check valve, which is designed to prevent backflow and protect water quality. The poly check valve must adhere to standards that specify its pressure resistance, temperature range, and chemical compatibility to prevent failure or contamination of the water supply.

Dimension and tolerance requirements are also clearly defined within pipe fitting standards. For instance, fittings intended to connect pipes with a nominal diameter of 2 inches must meet certain diameter and threading specifications to ensure a tight, leak-free connection. This becomes especially critical when dealing with valves such as a 2 inch gas solenoid valve that might be used in water systems requiring automated control of fluid flow. Although primarily associated with gas systems, solenoid valves of this size and specification are increasingly found in water management for their ability to precisely regulate flow electronically. The standards ensure that these valves can be integrated safely and that the fittings around them maintain the system's pressure and flow parameters.

The installation process also benefits from adherence to pipe fitting standards. Proper installation ensures that fittings are sealed correctly and that mechanical stresses do not exceed design limits. For example, when installing a water spigot shut off valve, it is essential to follow guidelines related to thread sealing, torque application, and orientation to avoid leaks or premature wear. Similarly, the poly check valve installation must account for the correct flow direction to maintain its check function. Incorrect installation can cause system failures or water contamination issues.

Standards also include testing and inspection requirements for pipe fittings and valves. Pressure testing, leak testing, and material certification are typical procedures to verify compliance. Before a water supply system is commissioned, fittings such as valves and check valves undergo these tests to ensure they can withstand operating conditions without degradation. Periodic inspections during maintenance also rely on these standards to identify components that may require replacement or repair.

In addition to physical and mechanical standards, environmental and safety considerations influence pipe fitting regulations. The materials used must be safe for potable water, meaning they should not leach harmful substances into the water. Components like poly check valves are often evaluated for compliance with drinking water safety standards. Furthermore, fire resistance, corrosion resistance, and UV resistance are considered for outdoor installations or industrial environments.

As water supply systems evolve with new technology, standards also adapt. The integration of automated components such as the 2 inch gas solenoid valve requires updated guidelines for electrical safety, electromagnetic compatibility, and control system integration. While the physical connection standards remain consistent, the additional electrical considerations ensure that the valve operates reliably without posing hazards.

In summary, pipe fitting standards for water supply systems encompass a range of technical and safety requirements that guide the selection, manufacturing, installation, and maintenance of components. Valves like the water spigot shut off valve, flow control devices such as the poly check valve, and electrically actuated fittings like the 2 inch gas solenoid valve all must comply with these standards to guarantee system performance and safety. Adhering to these guidelines helps maintain water quality, prevent leaks, and extend the service life of water supply infrastructure.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US