Ball valves and gate valves are two commonly used types of valves in plumbing and industrial piping systems. Both serve important roles in controlling the flow of liquids or gases, but they operate quite differently and are suited to different applications. Understanding their key differences can help in selecting the right valve for a specific purpose, especially when considering factors such as water safety shut off valve needs, handling of high temperature fluids, or managing pressure within a system.

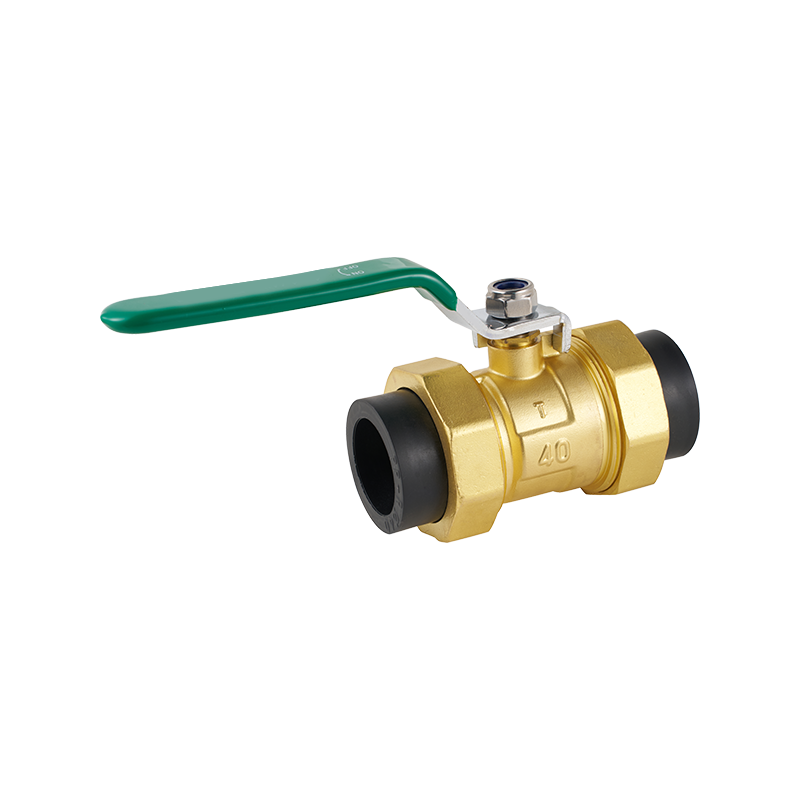

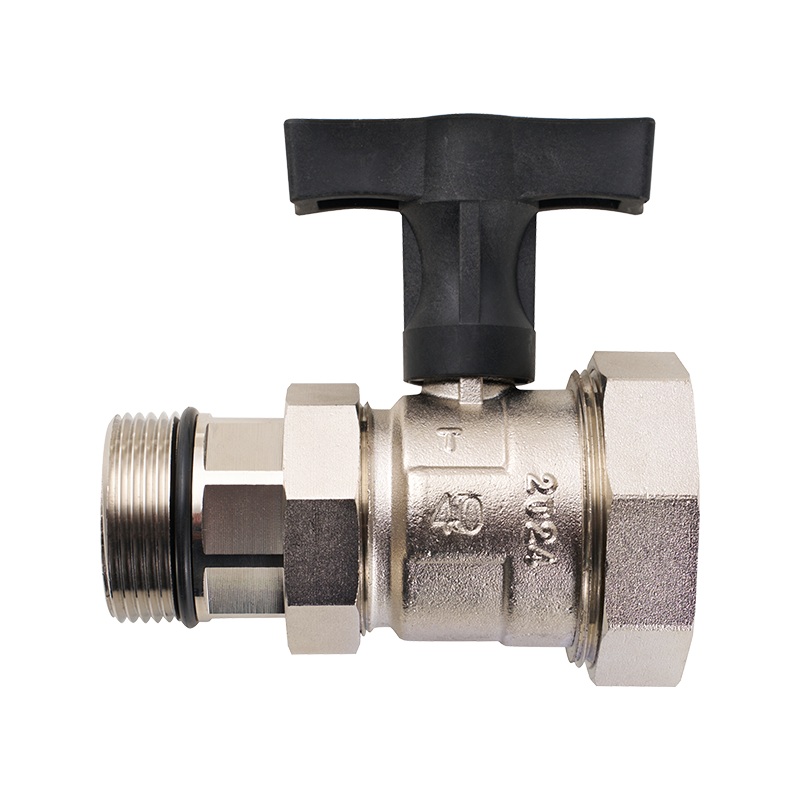

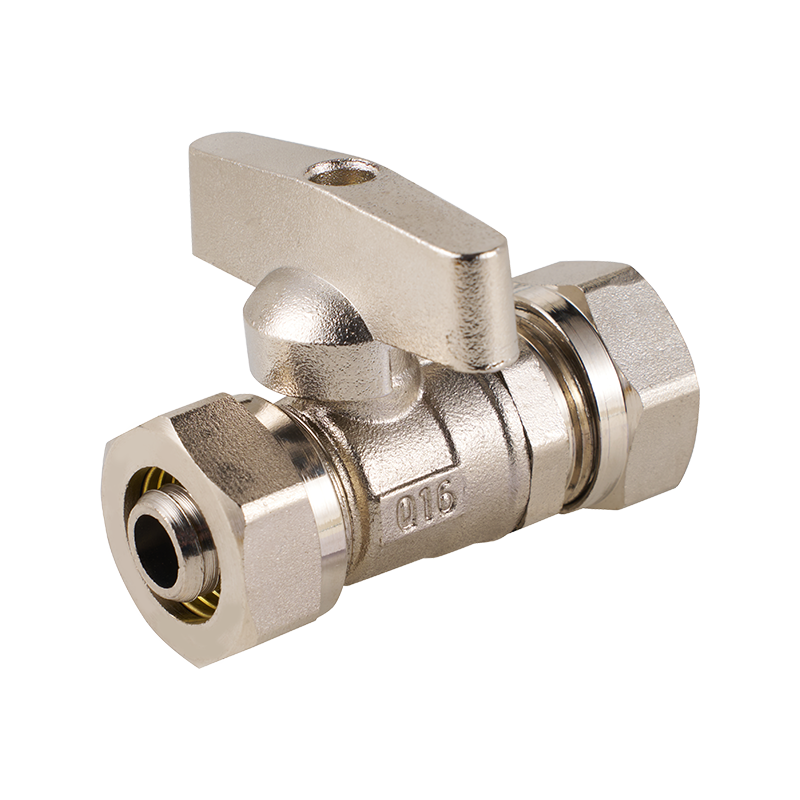

At their core, ball valves use a spherical ball with a hole through the center. When the valve handle turns the ball so that the hole aligns with the pipe, fluid flows freely. Turning the handle to rotate the ball perpendicular to the flow stops the fluid completely. This simple mechanism allows for quick on/off control, making ball valves ideal as water safety shut off valves in residential and commercial plumbing. Because they offer tight sealing and a compact design, ball valves reduce the risk of leaks, which is critical when shutting off water supplies to prevent damage or contamination.

Gate valves, in contrast, operate by raising or lowering a flat or wedge-shaped gate inside the valve body. When the gate is lifted, the valve is open, allowing fluid to flow through a straight path. Lowering the gate blocks the flow. Gate valves are generally used in applications where a fully open or fully closed position is needed, but rapid shutoff is not essential. Because the fluid flows in a straight line when open, gate valves introduce very little pressure drop, making them suitable for high-flow systems.

One notable difference between these two valve types is their operation speed. Ball valves can be opened or closed quickly with a quarter-turn rotation, which is why they often serve as shutoff valves for emergencies or regular maintenance. Gate valves require multiple turns to move the gate up or down, so they are slower to operate. This slower action makes them less suited for frequent use but beneficial in systems where gradual flow control is desired.

When dealing with high temperature fluids, the choice of valve also matters. Ball valves typically perform well under moderate temperature ranges, but in applications involving steam or hot liquids, a high temp check valve or a valve designed for heat resistance might be necessary. Gate valves, depending on their material and design, can sometimes better withstand higher temperatures, though both types require careful material selection to match the operating environment.

Another aspect to consider is pressure management. High pressure reducing valves are specialized components that lower pressure from a higher input to a safer output level, ensuring system protection. While ball valves and gate valves primarily control flow by opening or closing, pressure-reducing valves actively regulate pressure, often integrated within or near valve assemblies for safety and efficiency.

Maintenance and longevity also differ between ball and gate valves. Ball valves, with their simple mechanism, generally require less maintenance and provide reliable sealing over time. Gate valves have more moving parts exposed to fluid, and the gate's seating surfaces can wear, especially if the valve is used to throttle flow rather than just open or close fully. Improper use of gate valves for throttling can advance to vibration and damage, which impacts system reliability.

In terms of installation, ball valves are compact and often lighter, making them suitable for confined spaces or where weight is a concern. Gate valves tend to be larger due to the rising stem and gate mechanism. This can influence the choice in systems where space or weight constraints exist.

Ultimately, the selection between ball valves and gate valves depends on the specific requirements of the system, including flow control speed, pressure conditions, temperature, and maintenance capabilities. For example, a water safety shut off valve in a residential building may benefit from a ball valve for quick and reliable isolation. Conversely, a large industrial pipeline that requires a small pressure drop and occasional flow isolation might favor a gate valve.

Additionally, in systems handling steam or hot fluids, pairing valves with high temp check valves can improve safety by preventing backflow and managing temperature stresses. Likewise, incorporating high pressure reducing valves ensures that pressure levels remain within safe operating limits, protecting the entire piping network.

In summary, ball valves and gate valves each offer distinct advantages and limitations. Choosing the appropriate valve involves assessing the operational needs, fluid characteristics, and safety requirements. Proper selection and installation contribute significantly to system performance and longevity, especially when valves like water safety shut off valves, high temp check valves, and high pressure reducing valves are part of the overall design strategy.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US