When working with polypropylene (PP) piping systems, selecting the appropriate valve is essential to ensure smooth operation, reliability, and ease of maintenance. Polypropylene pipes are widely used in various applications due to their chemical resistance, lightweight nature, and durability. However, their compatibility with valves and fittings requires careful consideration. Choosing the right valve involves understanding the system's needs, flow requirements, and maintenance factors.

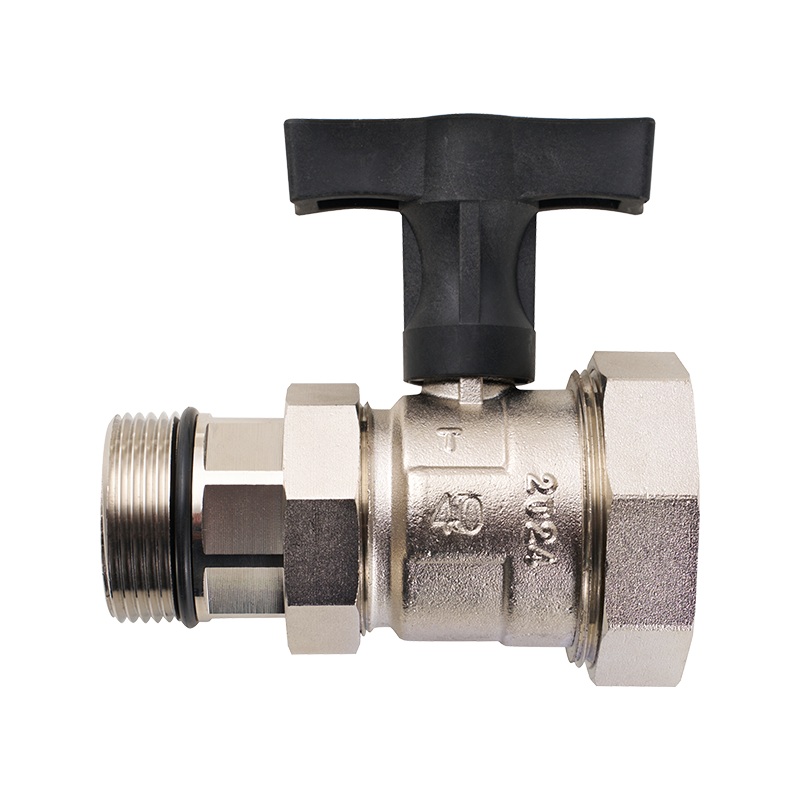

One of the common valve types used in PP piping systems is the ball valve water tap. This valve is appreciated for its simple design and reliable shut-off capabilities. Ball valves feature a spherical disc that rotates to control the flow of liquid through the pipe. When the valve handle is turned 90 degrees, the flow either stops completely or allows full passage. The ball valve water tap is particularly useful for manual control in residential and industrial water systems connected to polypropylene pipes. Its design enables quick opening and closing with small effort, which is important in systems where frequent valve operation is expected.

In systems where monitoring and control of flow rates are important, integrating a flow meter shut off valve can be highly beneficial. This valve combines the ability to measure the flow rate with the capacity to stop the flow when necessary. The flow meter component helps operators track fluid movement through the polypropylene piping, providing valuable data for system performance and efficiency checks. When paired with a shut off valve function, it also allows for quick isolation of certain sections of the piping system without interrupting the entire network. This dual functionality helps improve operational control while maintaining system integrity.

Another valve variant to consider in PP piping systems is the strainer ball valve. This type of valve integrates a strainer element within the ball valve, helping to filter out debris and particles that might otherwise cause blockages or damage downstream equipment. The strainer ball valve is particularly useful in systems where fluid cleanliness is a concern, such as water treatment or chemical processing applications. By catching contaminants at the valve, it helps reduce maintenance needs and protects pumps, sensors, and other components from wear caused by particulates. Additionally, the ball valve design ensures reliable shut-off, combining filtration and flow control in one unit.

Material compatibility is a key factor when choosing valves for polypropylene pipes. Valves must be made from materials that can handle the chemical properties of the transported fluid without degrading or corroding. Common materials for valves used in PP systems include polypropylene itself, PVC, or stainless steel for parts that require added strength or corrosion resistance. Selecting a valve with compatible materials ensures a longer service life and reduces the risk of leaks or failures.

Installation considerations also play a role in valve selection. Polypropylene piping is often joined using heat fusion or mechanical fittings, so valves designed to integrate seamlessly with these connection methods help simplify installation and reduce potential weak points in the system. For example, socket fusion-compatible ball valves are often preferred because they can be joined securely with the pipes, creating a continuous flow path that resists leaks. Furthermore, valves that are easy to maintain or replace without extensive system downtime are preferred in practical applications.

The operating pressure and temperature of the system must be matched with the valve's specifications. Polypropylene pipes generally operate under moderate pressure and temperature ranges, so valves selected should fall within these limits to avoid damage or deformation. For systems with fluctuating conditions, valves that provide stable performance across a range of pressures and temperatures contribute to system reliability.

In terms of maintenance, valves that can be easily cleaned or serviced contribute to the overall efficiency of polypropylene piping systems. The strainer ball valve, for instance, allows periodic removal of accumulated debris without dismantling large portions of the piping. Similarly, valves that allow quick shut-off during repairs or inspections lessen the need for full system shutdowns, reducing operational interruptions.

In summary, choosing the right valve for polypropylene piping systems requires balancing several factors, including valve type, material compatibility, installation methods, and system operating conditions. The ball valve water tap remains a practical choice for general shut-off and flow control due to its simplicity and reliability. The flow meter shut off valve adds a layer of operational monitoring and control, improving management of fluid flow. Meanwhile, the strainer ball valve offers combined filtration and flow control to protect system components and reduce maintenance. Paying attention to these details ensures polypropylene piping systems function smoothly and maintain durability over time.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US