Valve corrosion is a common issue that can affect the reliability and lifespan of plumbing systems. Understanding the causes of corrosion and how to prevent it is essential for maintaining efficient operation and avoiding costly repairs. This article explores valve corrosion, its impact on different types of valves, and practical methods to reduce its occurrence, with particular attention to valves such as the in wall water shut off valve, ball valve outdoor faucet, and thermostatic shower control valve.

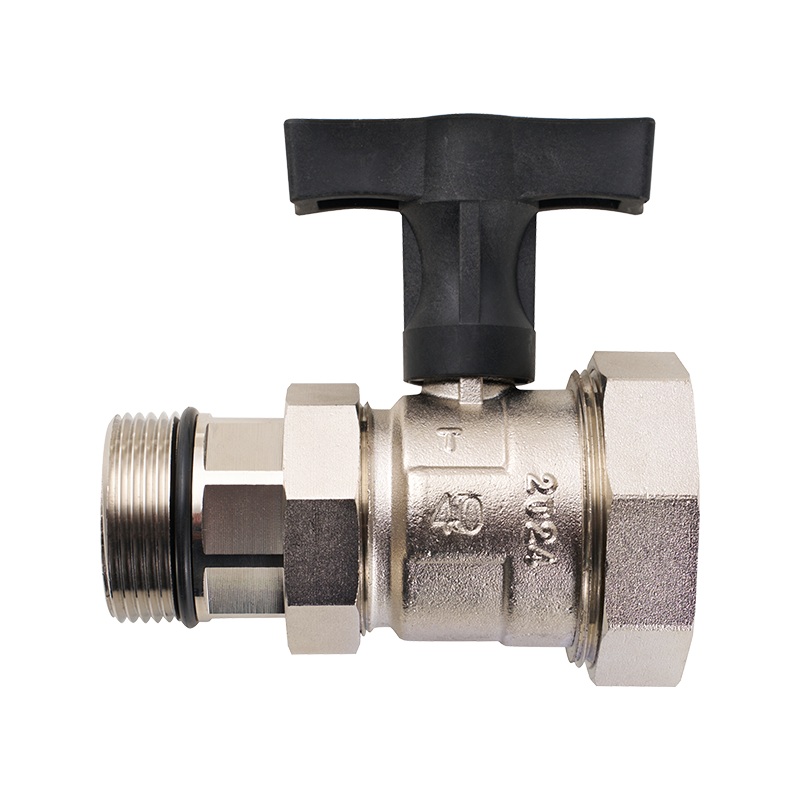

Corrosion occurs when metal components react chemically with their environment, pilot to material degradation. In plumbing valves, corrosion can result from exposure to water, oxygen, chemicals, and varying temperatures. Over time, this process can weaken valve bodies, cause leaks, or hinder valve operation. For instance, an in wall water shut off valve, which is typically installed inside walls to control water flow to specific fixtures, can suffer from corrosion if moisture seeps into its housing or if the water contains corrosive elements like high levels of chlorine or acidic pH. Corroded valves not only reduce water quality but can also become difficult to operate or completely fail.

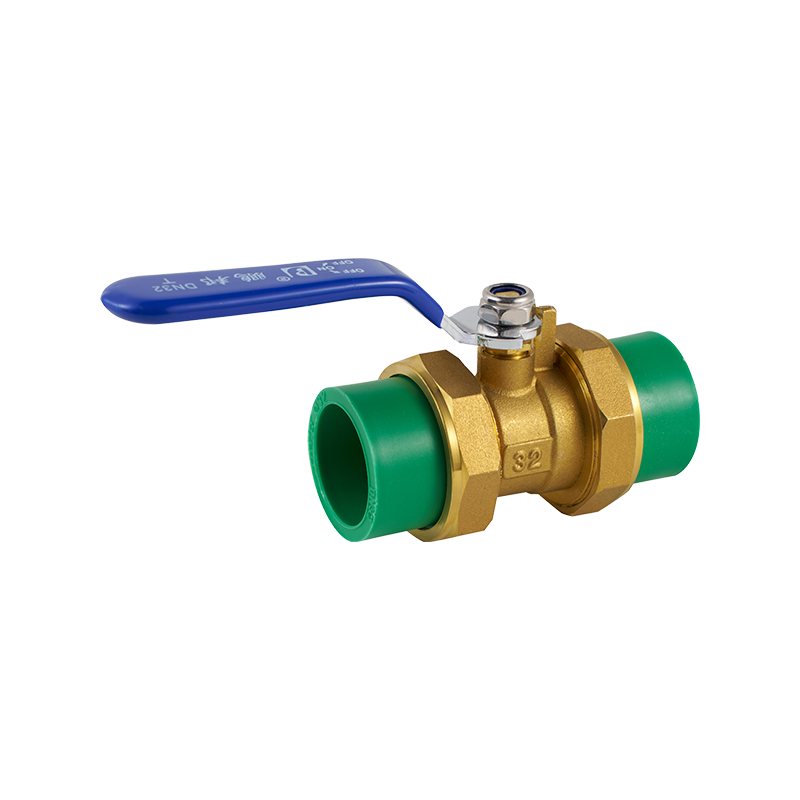

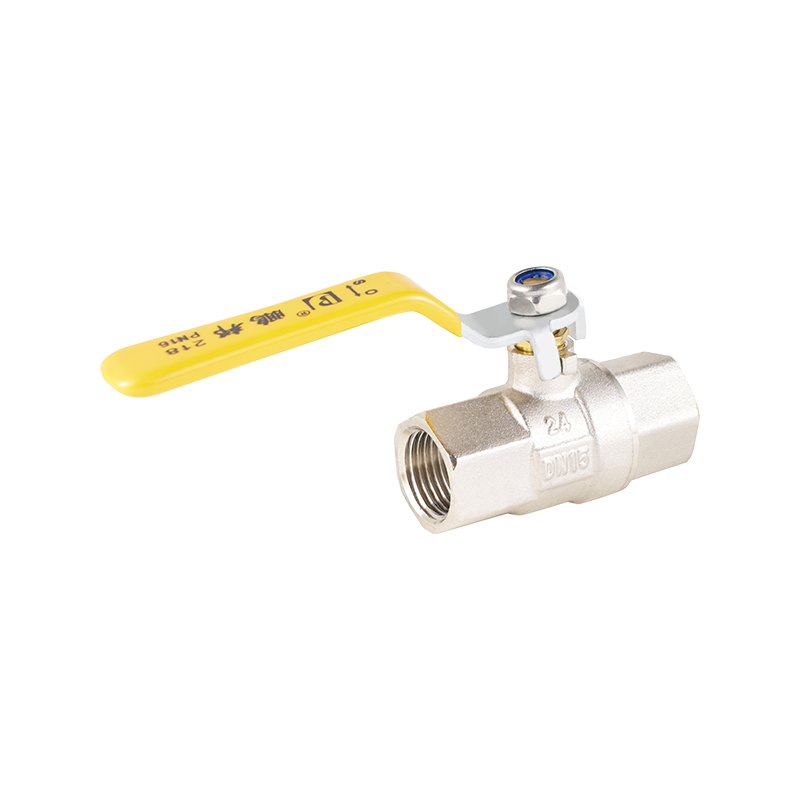

One example prone to corrosion is the ball valve outdoor faucet. Because it is exposed to outdoor conditions, including rain, temperature fluctuations, and dirt, this type of valve faces more environmental stress than indoor valves. Corrosion on outdoor ball valves can advance to stiff operation or water leakage, which affects outdoor water usage for gardening, cleaning, or irrigation. Regular inspection and maintenance are critical for such valves to catch early signs of corrosion and address them promptly.

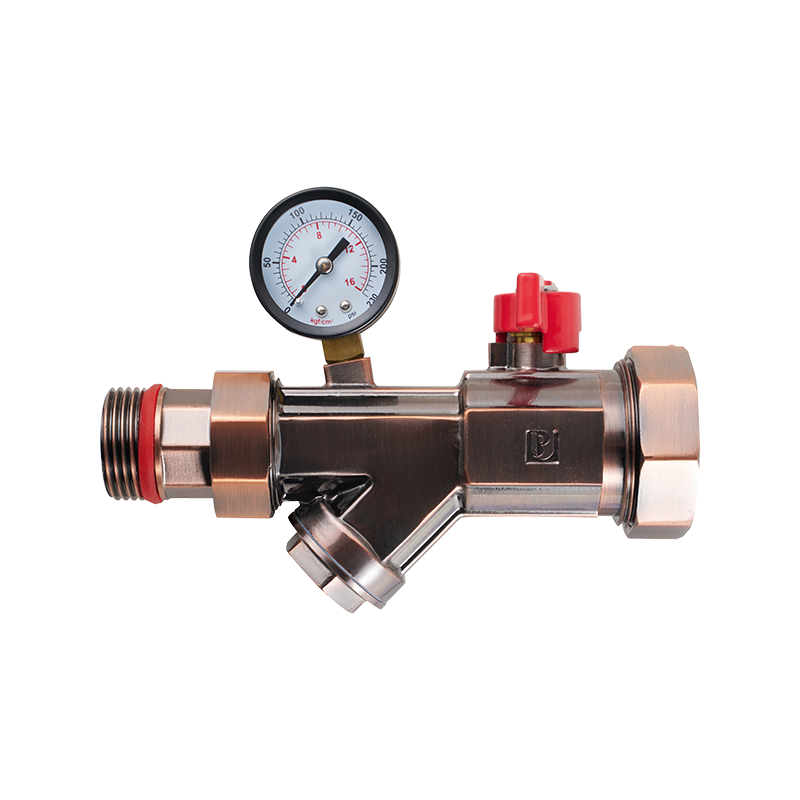

Another valve that can be affected by corrosion is the thermostatic shower control valve. This valve is essential for regulating water temperature in showers, mixing hot and cold water to provide a steady output. Because it operates with both hot and cold water and is constantly exposed to moisture, it can be susceptible to corrosion on internal components if water quality is poor or if mineral deposits build up over time. Corrosion in these valves can cause inaccurate temperature control or reduce water flow, impacting user comfort and safety.

Preventing valve corrosion requires a combination of appropriate material selection, installation practices, and routine maintenance. Many valves today are manufactured using corrosion-resistant materials such as brass, stainless steel, or specially coated metals to improve durability. Choosing valves made from these materials is one step toward reducing corrosion risks. For example, selecting an in wall water shut off valve with a brass body can offer better resistance to water-related corrosion compared to valves made from less durable metals.

Proper installation also plays a role in corrosion prevention. Ensuring that valves are installed in locations that have less exposure to moisture or chemical elements helps prolong their service life. For outdoor ball valves, adding protective covers or insulating the valve can reduce direct exposure to rain and temperature changes. When installing a therlots ofatic shower control valve, it's important to follow manufacturer guidelines and ensure the water supply is adequately filtered to reduce sediments and minerals that contribute to corrosion.

Regular maintenance routines help detect early corrosion signs and keep valves functioning smoothly. Flushing the system periodically to remove sediments, inspecting valve surfaces for discoloration or roughness, and lubricating moving parts are practical steps. In the case of an outdoor ball valve faucet, winterizing by draining water and shutting off the valve before freezing weather can prevent damage caused by ice expansion. For the therlots ofatic shower control valve, periodic cleaning and descaling may be needed to prevent mineral buildup that can accelerate corrosion.

Water quality management is another important factor in controlling corrosion. Monitoring pH levels, hardness, and chlorine content can help determine if additional treatment is needed. Installing water softeners or filtration systems can reduce corrosive elements and extend valve life. This approach is especially relevant for in wall water shut off valves, where poor water quality hidden inside walls can cause unnoticed corrosion until leaks or failures occur.

In conclusion, valve corrosion is an issue that affects various valve types across plumbing systems, including in wall water shut off valves, ball valve outdoor faucets, and therlots ofatic shower control valves. Understanding the causes and implementing preventive measures can help maintain system integrity and functionality.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US