Leaks not only result in water or fluid loss but can also cause damage to surrounding materials, advance to pressure drops, and affect system performance. This is especially critical in systems where precise control and fluid direction are necessary, such as in heating, irrigation, or domestic plumbing systems.

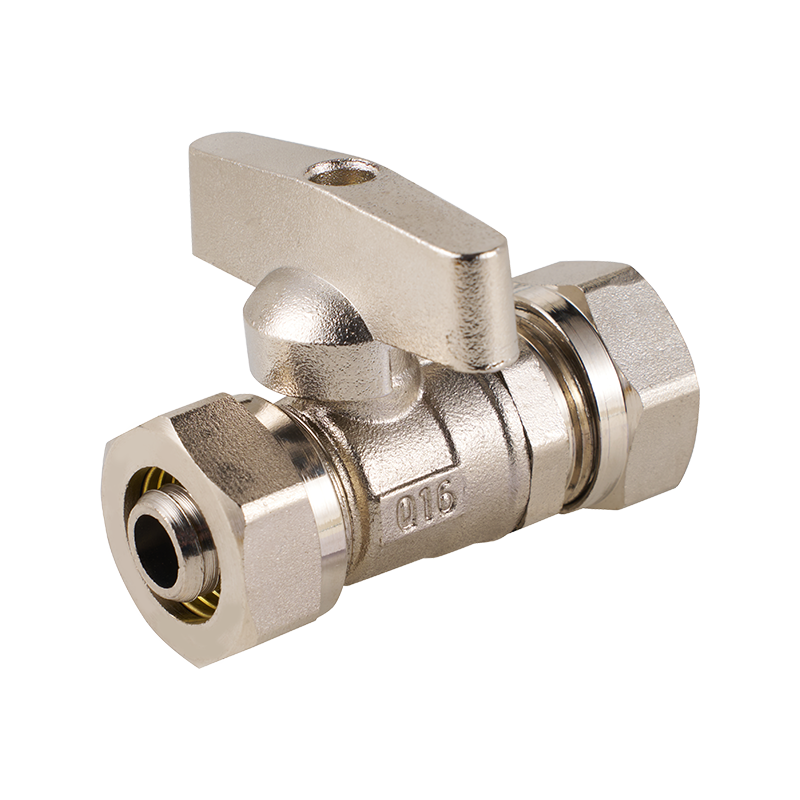

A leak-free valve connection is the result of a combination of quality materials, proper installation practices, and system-compatible components. For example, when working with outdoor water supply systems, using an outdoor water faucet ball valve ensures better control over water flow while maintaining resistance to external environmental factors. These valves are often exposed to changing temperatures, UV light, and moisture, making proper sealing and durable materials essential. A minor leak in such areas can go unnoticed for days or weeks, resulting in unnecessary water loss and increased maintenance needs.

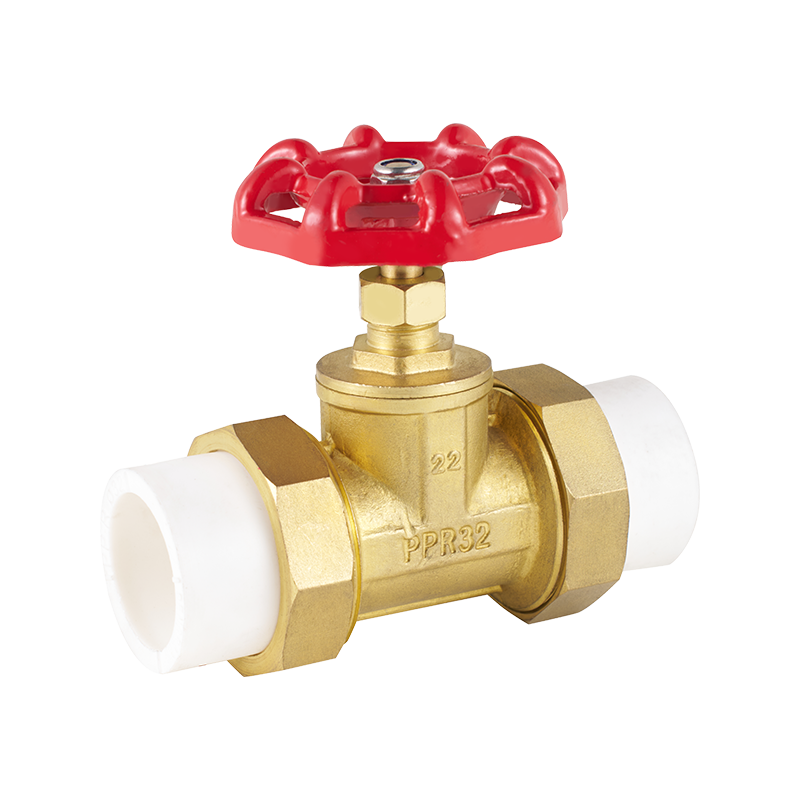

One commonly used component in achieving leak-free connections is the stainless steel shut off valve. Its corrosion-resistant properties and robust structure make it suitable for both residential and industrial applications. These valves are typically placed at key junctions in a pipeline to isolate sections for maintenance or emergency shut-off. Ensuring these valves are tightly sealed and properly integrated into the system reduces the risk of sudden failures and enables quick responses when needed. In many cases, stainless steel valves also offer better compatibility with various pipe materials, further improving sealing integrity.

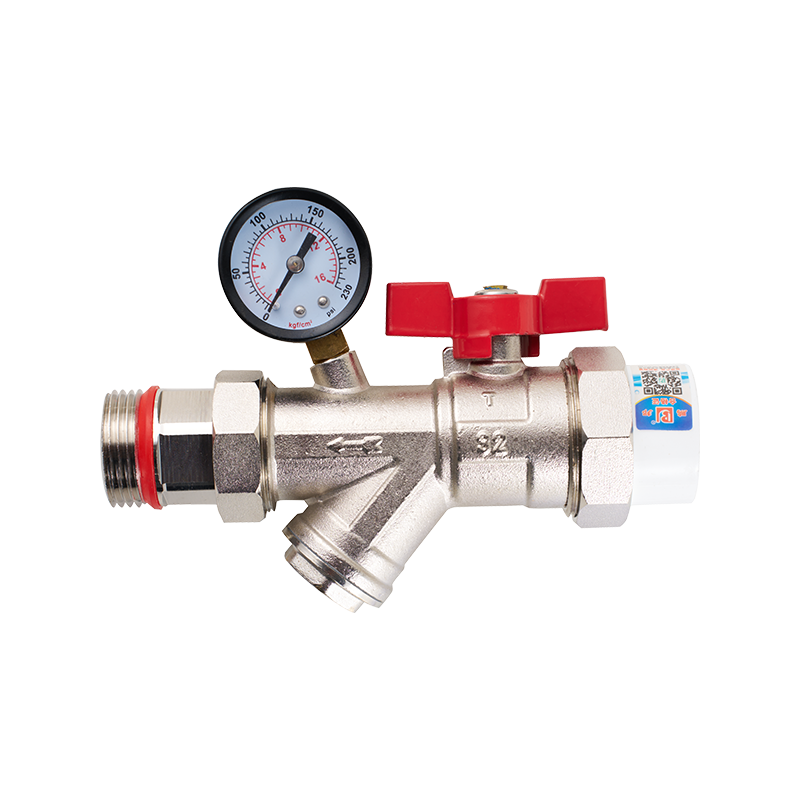

Another important component in systems that require direction control is the 3 port check valve. This type of valve is used to allow flow in a specific direction while preventing backflow, which can compromise the functionality of pumps or heating circuits. In hydronic heating systems, for instance, a 3 port check valve helps manage circulation paths, especially when multiple zones are involved. A leaky connection at any point in this setup can advance to inefficiencies such as uneven heating, air introduction, or even pipe damage from unregulated pressure. That's why these valves need to be not only structurally reliable but also properly installed using compatible sealing methods.

Threaded and welded joints, both common in valve connections, require attention to detail. Threaded connections need to be tightened according to specification and often use sealing tape or compounds to ensure no gaps are present. Over-tightening can damage threads and cause leaks over time. On the other hand, welded joints, while offering stronger structural bonds, require professional techniques to avoid micro-cracks that could become future leakage points. When installing a stainless steel shut off valve, the choice between threaded or welded installation depends on system pressure, accessibility, and maintenance preferences.

Material compatibility also plays a key role. Connecting a stainless steel valve to a dissimilar metal pipe without the proper fittings may advance to galvanic corrosion, which weakens the connection over time and encourages leaks. Using dielectric unions or selecting similar materials can prevent this issue. Similarly, in outdoor environments, a valve like the outdoor water faucet ball valve must be paired with weather-resistant piping to ensure long-term integrity.

Preventive maintenance is another factor in preserving leak-free conditions. Over time, seals, gaskets, and O-rings may degrade, especially under frequent temperature fluctuations. Periodic inspections and timely replacement of worn parts are essential. In systems using 3 port check valves, ensuring that the check mechanism is free of debris and functions smoothly also helps prevent unintentional leakage.

In conclusion, leak-free valve connections are not a one-time achievement but a result of smart component selection, proper installation, and ongoing care. Whether it's a stainless steel shut off valve in an industrial pipeline, an outdoor water faucet ball valve in a garden system, or a 3 port check valve in a heating network, the focus must remain on ensuring that every connection holds its seal. A small leak today can become a big problem tomorrow, and attention to these details helps maintain system safety, efficiency, and longevity.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US