Ensuring smooth operation and long service life for fluid systems relies heavily on the careful maintenance of critical components. Among these, the Double Union Ball Valve and the Manual Temperature Valve play significant roles in controlling fluid flow and temperature. Proper maintenance of these valves not only prevents leaks and mechanical failures but also supports consistent system performance, especially in heating, cooling, and industrial applications.

Regular Inspection and Early Detection of Wear

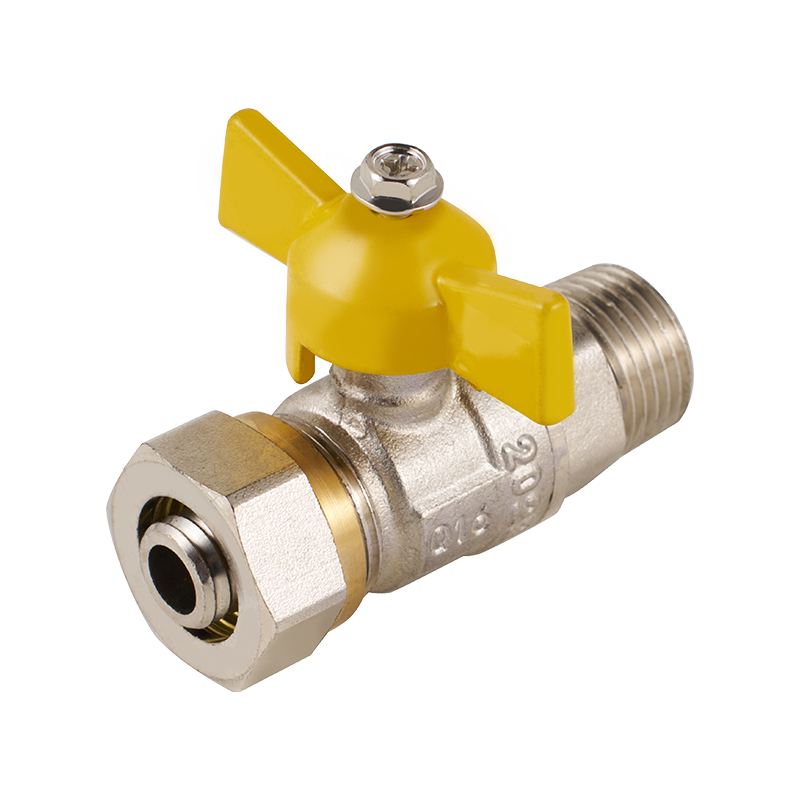

Double Union Ball Valves are designed with a union structure that allows easy removal for inspection and maintenance. Regular inspection is crucial to identify signs of wear before they escalate into operational problems. Key points to examine include union connections, valve body, and visible seal areas. Seals, gaskets, and O-rings are susceptible to aging, compression, and wear over time, which may cause leakage or loss of pressure.

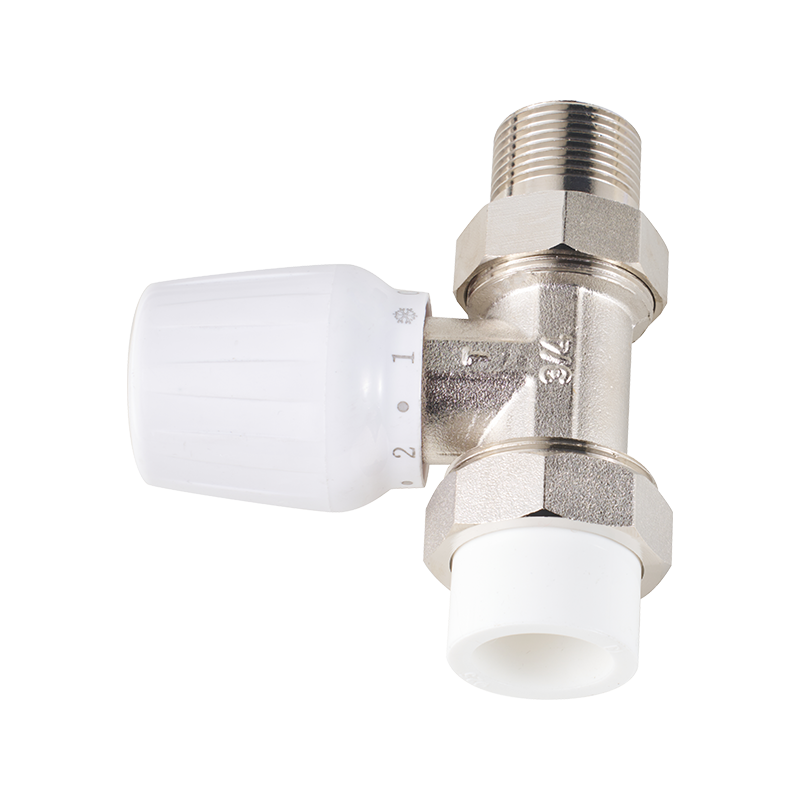

For Manual Temperature Valves, inspection should focus on the handle, stem, and internal control mechanism. Observing valve operation under normal flow conditions helps detect stiffness, unusual resistance, or minor leaks. Early identification of these issues allows timely corrective actions, preventing inaccurate temperature control or unexpected flow interruptions that could impact the entire system.

Cleaning Procedures and Internal Maintenance

Mineral deposits, scale, and debris accumulation are common challenges in fluid systems. Disassembling the valve allows access to the ball, seats, and internal surfaces, which should be cleaned with suitable solvents or brushes. Accumulated debris can cause uneven seating or increase the effort required to operate the valve. After cleaning, applying a compatible lubricant to the ball and stem reduces friction, preserves the seals, and ensures smooth rotation.

Manual Temperature Valves also benefit from regular cleaning of internal passages. Over time, sediment can obstruct flow paths, reducing the valve’s ability to adjust temperature accurately. Ensuring that all passages are clear and lubricating moving components where applicable helps maintain consistent manual operation.

Functional Testing and Operational Checks

Inspection and cleaning should always be accompanied by functional testing. Double Union Ball Valves need to be fully opened and closed multiple times to ensure the ball rotates freely and seats correctly without obstruction. Resistance, binding, or uneven movement may indicate internal wear, deposits, or misalignment. Addressing these problems promptly helps prevent leaks and maintains reliable operation.

Similarly, Manual Temperature Valves should be tested across their entire temperature adjustment range. Observing the response of the system to changes in handle position allows detection of slow or delayed adjustments, which may signal wear in the stem packing or internal components. Regular testing ensures accurate temperature control and reduces the risk of system inefficiency or overcompensation.

Replacement of Wear and Consumable Parts

Both valve types contain components that are prone to wear and require periodic replacement. In Double Union Ball Valves, the primary wear items include seats, gaskets, and O-rings. Replacing these elements as they show signs of deterioration maintains tight sealing and prevents leakage. In Manual Temperature Valves, stem packing, handle mechanisms, and internal flow regulators may need attention. Using components that match the original specifications is essential to maintain correct operation and prevent mismatched performance or accelerated wear.

Additional Considerations for Longevity

Environmental conditions, fluid composition, and operating pressures can significantly affect valve lifespan. Valves in systems with abrasive fluids, high temperatures, or fluctuating pressures may require more frequent inspection and maintenance. For Double Union Ball Valves, ensuring proper torque on union nuts during reassembly prevents leaks while avoiding over-tightening that could damage seals. Manual Temperature Valves may benefit from calibration checks to ensure that the set positions correspond accurately to desired temperatures.

Documentation of maintenance activities—including inspection dates, parts replaced, and operational observations—helps create a maintenance history. This record supports planning for preventive maintenance, reduces unexpected failures, and extends the functional life of both valve types.

Integrating Maintenance into System Management

Consistent maintenance practices for Double Union Ball Valves and Manual Temperature Valves contribute to smoother operation of entire fluid systems. By combining regular inspection, cleaning, functional testing, timely replacement of parts, and thorough documentation, operators can prevent leaks, maintain accurate temperature and flow control, and reduce the need for emergency interventions. Integrating these maintenance steps into routine system management ensures that valves continue to operate effectively over time, supporting stable and efficient system performance.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US