When HVAC systems undergo upgrades or retrofits, components like the Double Union Ball Valve and Manual Temperature Valve are often prioritized for their balance of practicality, performance, and ease of integration. For engineers managing existing buildings or older mechanical setups, these valves offer dependable control without the need for extensive automation or costly redesigns. Their simplicity and adaptability make them well-suited for projects where efficiency improvements are required within the limits of existing infrastructure.

Manual Temperature Valves and Their Role in Retrofit Projects

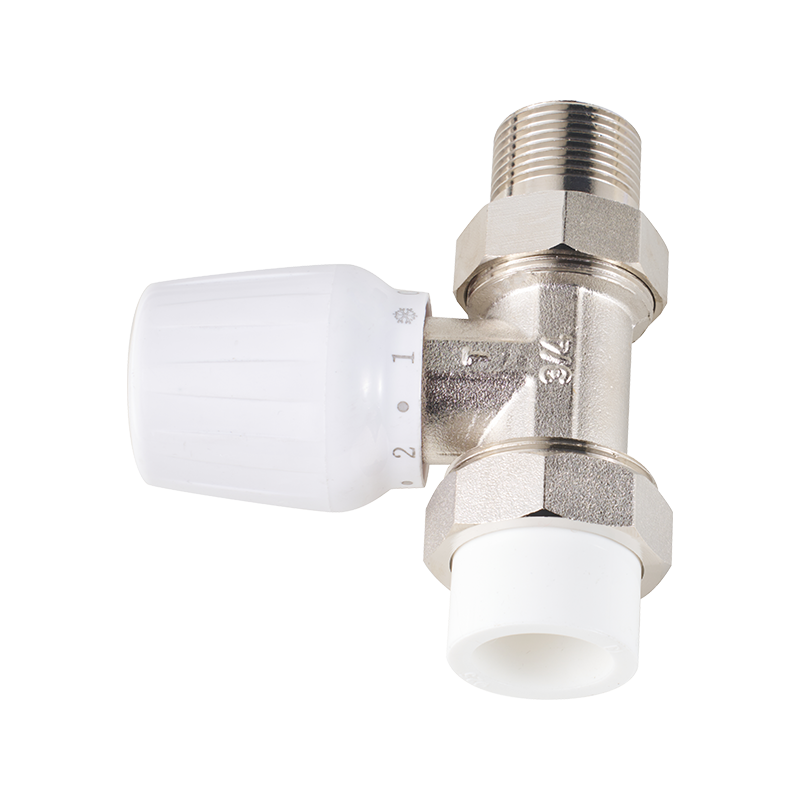

Retrofitting HVAC systems often involves modernizing certain components while maintaining the original piping and mechanical framework. In these situations, the manual temperature valve provides a straightforward solution for controlling heating or cooling output without requiring new electronic control systems. By manually regulating the flow of water or other fluids, engineers can fine-tune temperature distribution across different zones, improving comfort and energy efficiency in older systems.

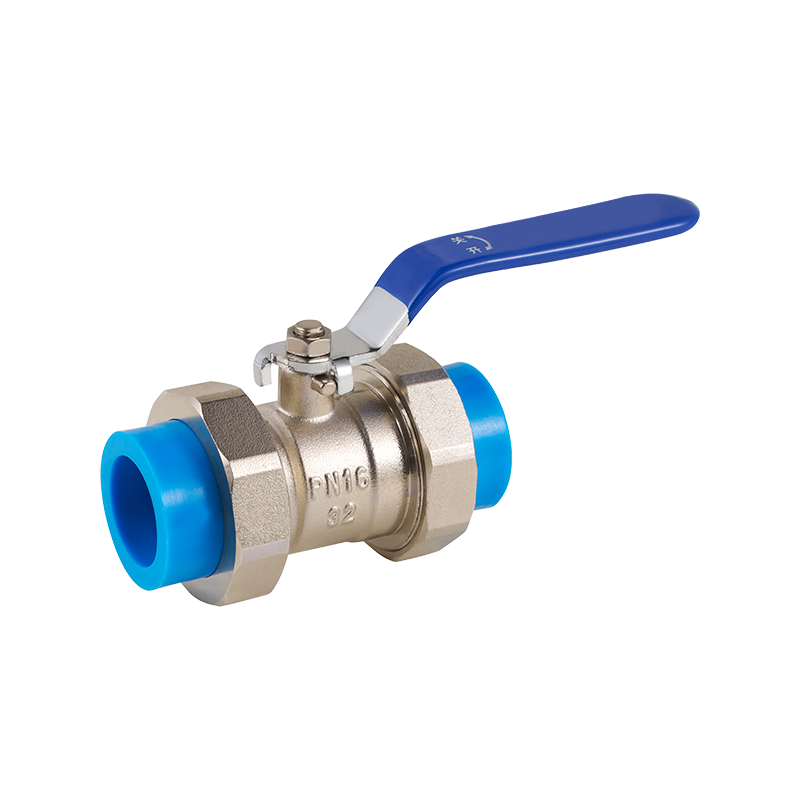

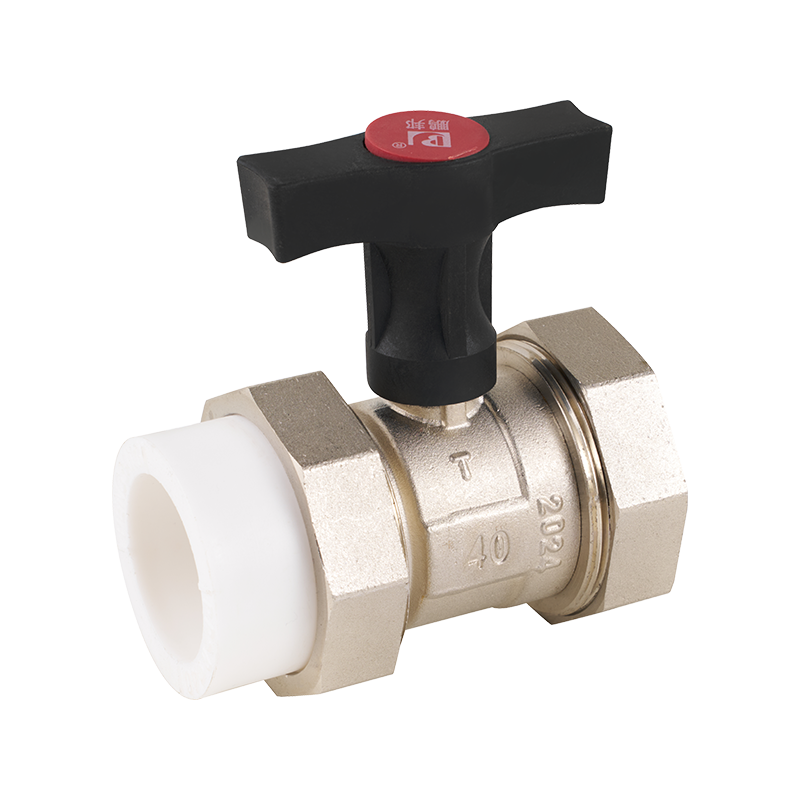

Integration Ease with Double Union Ball Valves

A Double Union Ball Valve often complements a manual temperature valve in retrofit projects. Its detachable ends allow easy installation or removal, which is valuable when working within confined spaces or existing pipelines. Engineers can isolate specific sections of the HVAC system for maintenance or modification without dismantling the entire line.

This flexibility is essential in retrofit work, where access points and layout changes may be limited. The combination of a double union ball valve and a manual temperature valve enables partial upgrades, controlled shutdowns, and quick replacements.

Why Engineers Choose Manual Control for System Balancing

In older HVAC systems, balancing temperature across multiple zones can be a challenge due to inconsistent flow rates and uneven heat exchange. Manual temperature valves give engineers direct control over flow adjustment, allowing precise balancing between different circuits. This manual fine-tuning ensures that each zone receives the right amount of heating or cooling without depending on automated sensors that might be incompatible with the existing setup.

Moreover, manual control helps diagnose and correct issues such as temperature lag, pressure drop, or valve sticking. During commissioning or testing, engineers can physically observe system response and make immediate corrections. This hands-on control is often preferred during retrofits, where on-site adjustments play a major role in optimizing performance.

Material Strength and Longevity for Older Systems

Retrofit projects frequently involve systems that have been in use for years, sometimes decades. In such cases, durability becomes a major consideration. Manual temperature valves and double union ball valves are typically made from materials like brass, stainless steel, or engineered alloys that resist corrosion and wear. This resilience allows them to function effectively even when fluid conditions are variable or water quality is less than optimal.

The mechanical simplicity of these valves also means fewer moving parts and less potential for electronic failure. For aging systems that need dependable operation without frequent replacement, these valves represent a practical and sustainable choice.

Cost and Installation Efficiency

Budget constraints are common in retrofit projects, and manual temperature valves are often selected for their cost-effectiveness compared to automated alternatives. They do not require power supplies, control wiring, or digital interfaces, which reduces installation time and overall project expenses.

When paired with a double union ball valve, the assembly becomes even easier to maintain. The union ends allow technicians to remove or replace the valve without cutting into pipes, saving labor and preventing unnecessary system disruption. For facilities that must remain operational during retrofits, this ease of maintenance is a major benefit.

Energy and Flow Optimization

Although manual temperature valves operate without automation, they still play an important role in energy efficiency. By adjusting flow precisely to match system demand, they help avoid overheating or overcooling, which in turn reduces energy waste. In retrofitted HVAC networks, where pumps, coils, and distribution systems may differ in age or capacity, this manual optimization can make a noticeable difference in overall energy performance.

The ability to regulate flow manually also prevents hydraulic imbalances that can strain pumps or reduce system efficiency. Engineers often use these valves to achieve stable flow distribution, ensuring that the system operates smoothly even after new components are integrated.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US