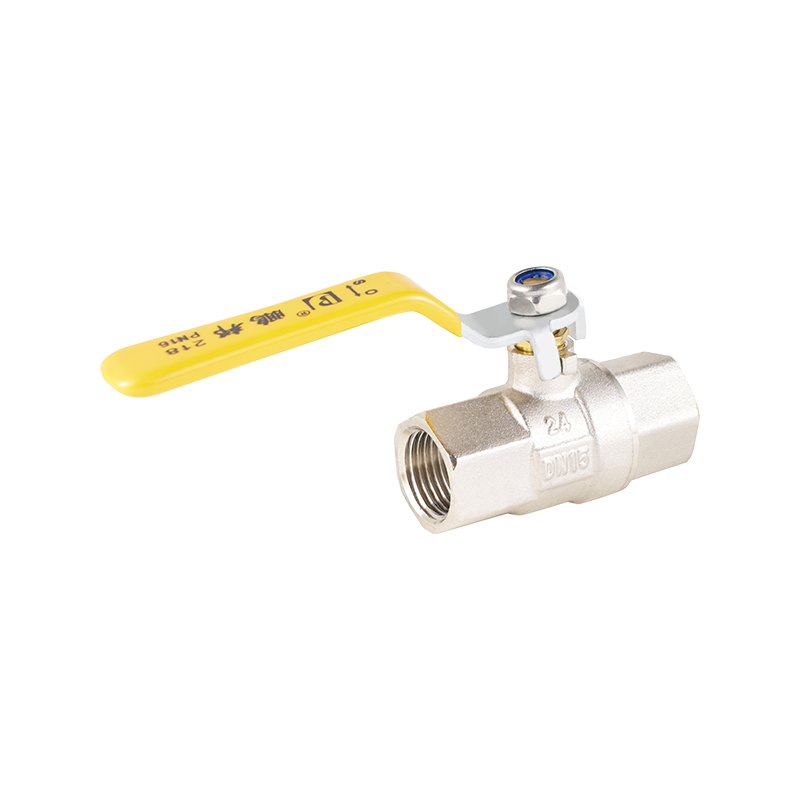

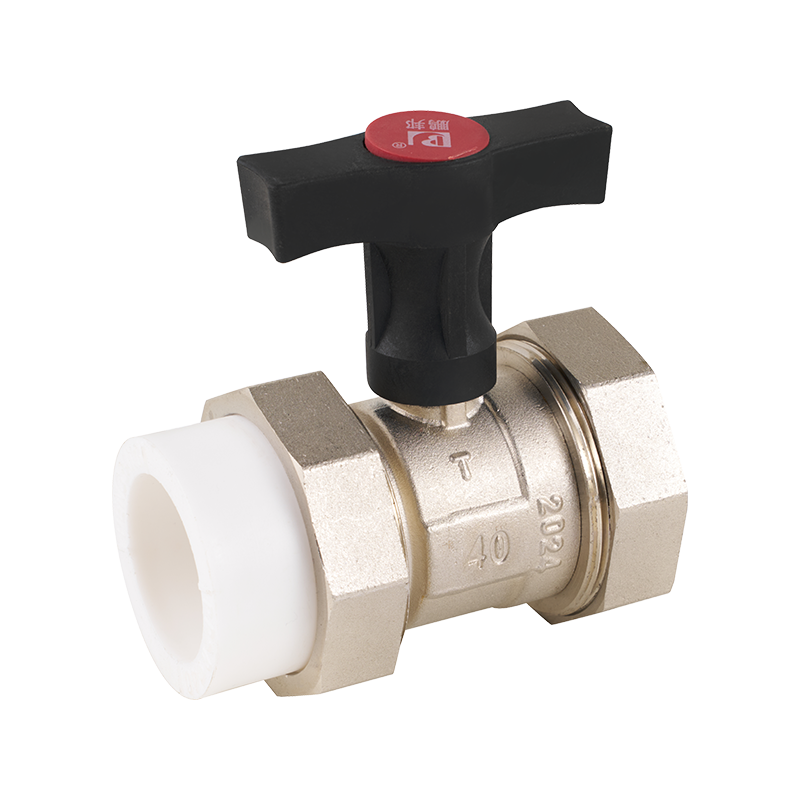

In process control systems where consistent performance and smooth operation are required, components such as the Double Union Ball Valve and the Manual Temperature Valve play an essential role in regulating flow and temperature. These two types of valves complement each other in managing pressure and maintaining efficiency within heating, cooling, or industrial fluid systems. Choosing the right manual temperature valve helps achieve balanced performance and operational stability without relying on complex automation.

The Role of Manual Temperature Valves in Process Stability

A manual temperature valve allows users to control fluid temperature by adjusting the flow rate of hot or cold media. This is particularly important in industries like chemical processing, HVAC systems, food production, and machinery cooling, where temperature variations directly affect product consistency or equipment safety.

Unlike fully automated valves, manual temperature valves are straightforward in design, reducing potential system faults caused by sensors or electronic controls. They provide an intuitive way for operators to respond quickly to system changes—useful in settings where immediate manual intervention is necessary.

Advantages of Manual Control in Complex Systems

In process environments that integrate multiple control components, such as a Double Union Ball Valve paired with a temperature valve, manual control offers flexibility. For example, when maintenance or testing is required, the double union design allows easy disassembly of the ball valve without disturbing pipe connections. At the same time, the temperature valve maintains control of the fluid conditions, ensuring the process remains stable during adjustments.

This combination of simplicity and precision makes manual temperature valves suitable for use in systems where operators prefer direct oversight. It also allows for incremental adjustments that can improve process accuracy without the need for complex calibration procedures.

Material Strength and System Compatibility

Durability is a key factor in selecting a manual temperature valve. Many models are made from brass, stainless steel, or reinforced alloys that resist corrosion and mechanical wear. Such materials ensure the valve continues to perform effectively even when exposed to high pressures, varying temperatures, or chemical media.

When paired with a double union ball valve, the installation becomes easier to service. The detachable ends of the ball valve enable quick replacement or inspection, which reduces downtime. Together, these valves form a dependable part of a system that prioritizes longevity and consistent operation.

Balancing Energy Efficiency and Performance

In process control, temperature regulation directly influences energy usage. Manual temperature valves help reduce unnecessary energy consumption by controlling flow precisely to meet operational demands. This ensures that heating or cooling systems run only as much as needed, preventing energy waste while maintaining desired conditions.

Ease of Maintenance and Long-Term Operation

Maintenance is often a deciding factor for engineers when choosing between manual and automatic valves. Manual temperature valves are straightforward to service and generally require minimal specialized knowledge. Routine checks, such as inspecting seals or testing flow response, can be completed quickly without interrupting the entire system.

In facilities where uptime is critical, this simplicity provides a clear advantage. Combined with the modular design of a double union ball valve, which can be easily removed and cleaned, operators can perform preventive maintenance efficiently. This reduces the risk of leaks or valve sticking, helping extend the lifespan of both components.

Application Versatility Across Industries

Manual temperature valves are used in a wide range of process systems—from heating circuits and cooling water loops to industrial washing and chemical mixing. In each case, the valve provides operators with hands-on control over the thermal balance of the system. The double union ball valve, often installed alongside, ensures flow direction and shutoff can be managed safely and quickly when required.

In manufacturing and building systems, this combination provides practical control over both temperature and flow, supporting smooth operation even in dynamic environments where process conditions change frequently.

Ensuring Operational Safety

Manual temperature valves often include safety-oriented design features, such as leak-resistant seals and stable handwheel mechanisms. When used in conjunction with a double union ball valve, they allow for isolated section control, preventing pressure build-up or unplanned flow changes. This layered approach helps maintain safe working conditions, especially in systems handling pressurized or heated fluids.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US