A closer look at everyday plumbing fixtures often begins with understanding how different flow structures behave, especially when products such as a Ball Valve Faucet and a PPR Ball Valve appear in similar installation scenes but serve slightly different purposes. Users in residential, commercial, or industrial settings often want to understand why flow rates feel different, how material choices influence performance, and what practical factors can guide a correct selection. Assessing flow characteristics is not only about numbers; it is also about recognizing how the internal structure, handle operation, installation method, and long-term maintenance needs shape actual use.

How Internal Valve Structure Shapes Flow Behavior

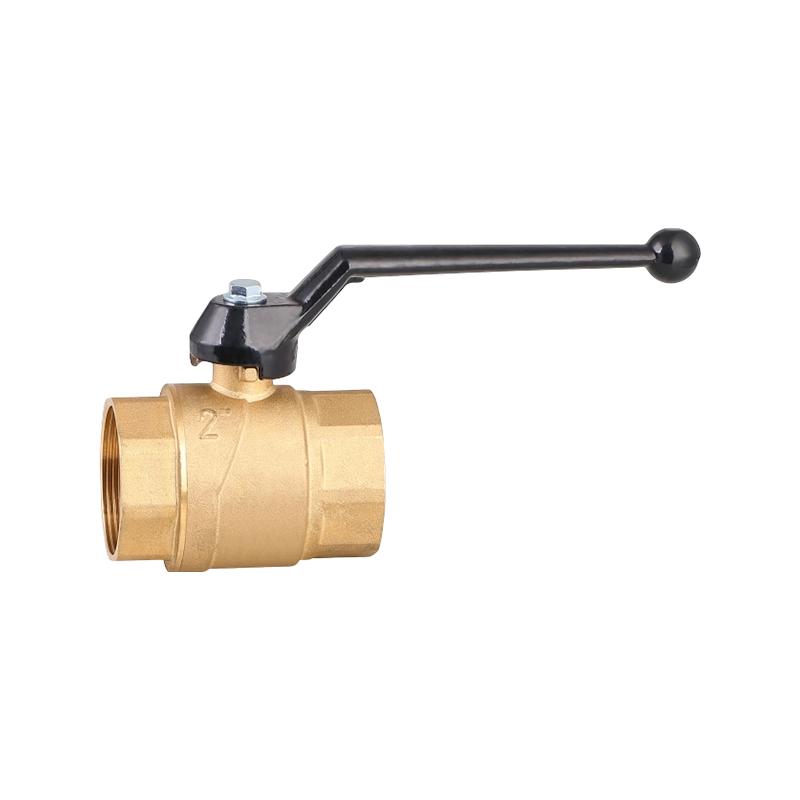

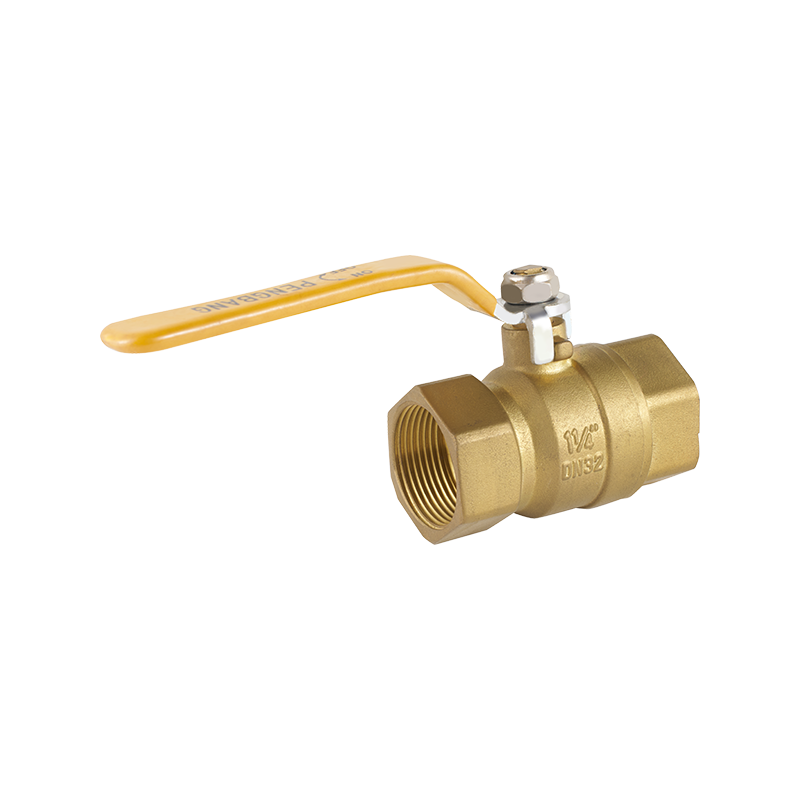

In a Ball Valve Faucet, the flow passage is often designed around everyday hand-operated use, where smooth operation and predictable turning angles matter. The spherical ball allows a quick 90-degree rotation from open to closed, which offers a stable flow path with relatively low internal obstruction. This structure supports consistent control when the faucet is used repeatedly in kitchens, bathrooms, or utility spaces.

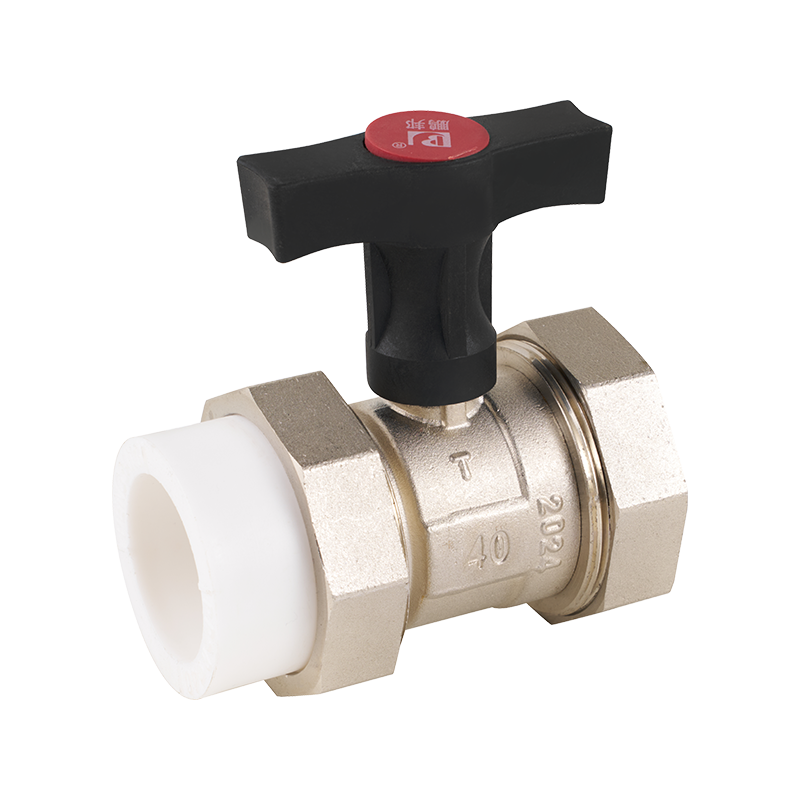

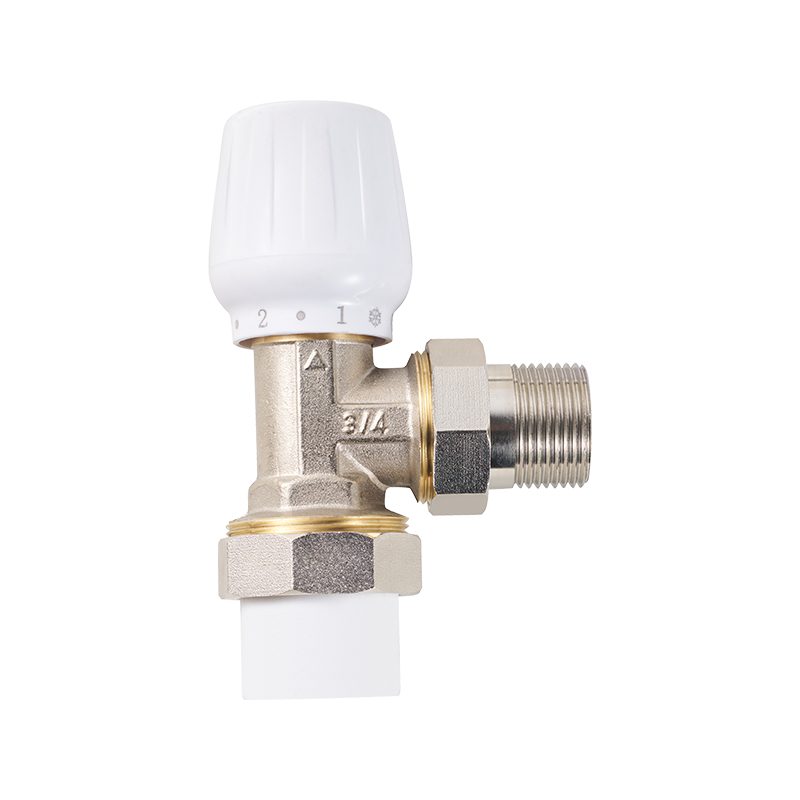

A PPR Ball Valve, meanwhile, features a similar ball-based structure but is typically integrated into pipe systems where long-term flow efficiency and resistance are important. Because PPR pipes are welded into closed systems, the valve’s inner diameter often aligns closely with the pipe itself, helping keep turbulence at a manageable level. When comparing the two, users can look at the size of the internal bore, the machining precision of the ball, and whether the valve is full-port or standard-port, as these aspects directly influence flow behavior.

Why Material Choices Affect Flow Stability and Durability

Material selection plays a functional role in long-term flow characteristics. Faucets that use metal bodies combined with a blue-handle design focus on durability and corrosion resistance, especially in areas exposed to frequent hand contact or changing water temperatures. A Ball Valve Faucet made from corrosion-resistant materials generally maintains internal smoothness for a long time, which reduces the likelihood of buildup that can influence flow.

PPR Ball Valves rely on polypropylene random copolymer (PPR) material, known for its resistance to scale accumulation and chemical exposure. For systems carrying hot water, aggressive fluids, or circulating water for long periods, PPR material helps maintain clean internal walls. This characteristic contributes to stable flow rates without requiring frequent internal cleaning. When users compare materials, it is helpful to consider factors such as water hardness, temperature cycles, and whether the installation involves treated or untreated water.

The Role of Handle Operation in Flow Control

Handle movement is another practical detail often overlooked when comparing flow characteristics. A metal faucet with a blue handle is typically designed for frequent adjustments, requiring a comfortable grip and smooth rotation. Because faucets are often turned repeatedly in short cycles, the handle shape and weight contribute indirectly to how easily users can regulate the desired flow.

For a PPR Ball Valve, the handle is shaped to provide clear indication of open or closed status. Since it is commonly used in system-line control rather than daily turning, smoothness, leverage, and visual alignment matter more than aesthetics. When comparing the two products, users should consider the amount of torque required to operate the valve, how smoothly the ball rotates inside the housing, and whether the design reduces strain for frequent or occasional use. These small differences influence how effectively a user can fine-tune water output.

Installation Mode and Its Impact on Flow Performance

Installation conditions significantly affect flow characteristics even when valves share a similar ball design. For faucets, installation usually connects to standard plumbing fittings, and the surrounding system remains open to atmospheric pressure. This means the Ball Valve Faucet often experiences variable inlet pressures depending on building water supply, pipe length, and elevation.

A PPR Ball Valve is joined by fusion welding within a closed pipeline system. Because there are fewer threaded joints and fewer internal transitions, the water flow tends to remain stable along the pipeline. A valve installed in such a system often presents less pressure loss. When comparing both, considering the pipe diameter, fitting transitions, and overall system layout helps users make an informed choice about which valve fits their expected flow performance in real applications.

How Sealing Structures Influence Long-Term Flow Reliability

Both types of valves use sealing components, but the sealing design influences how flow changes over time. The faucet version may combine O-rings with precision-machined internal surfaces, which supports stable operation even with frequent turning. Regular maintenance, such as cleaning mineral deposits around the handle or replacing seals, helps maintain performance.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US