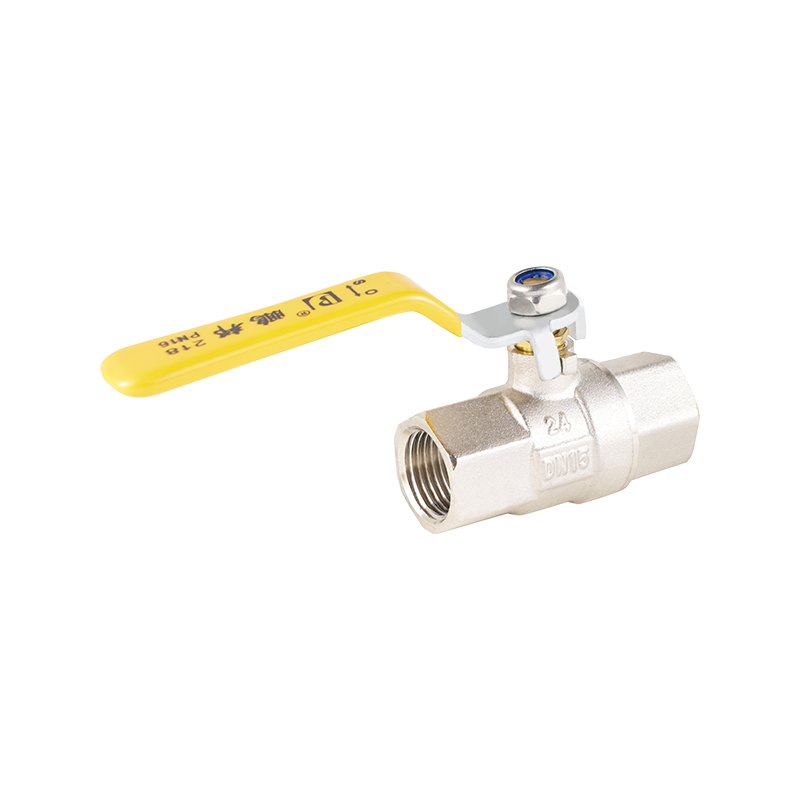

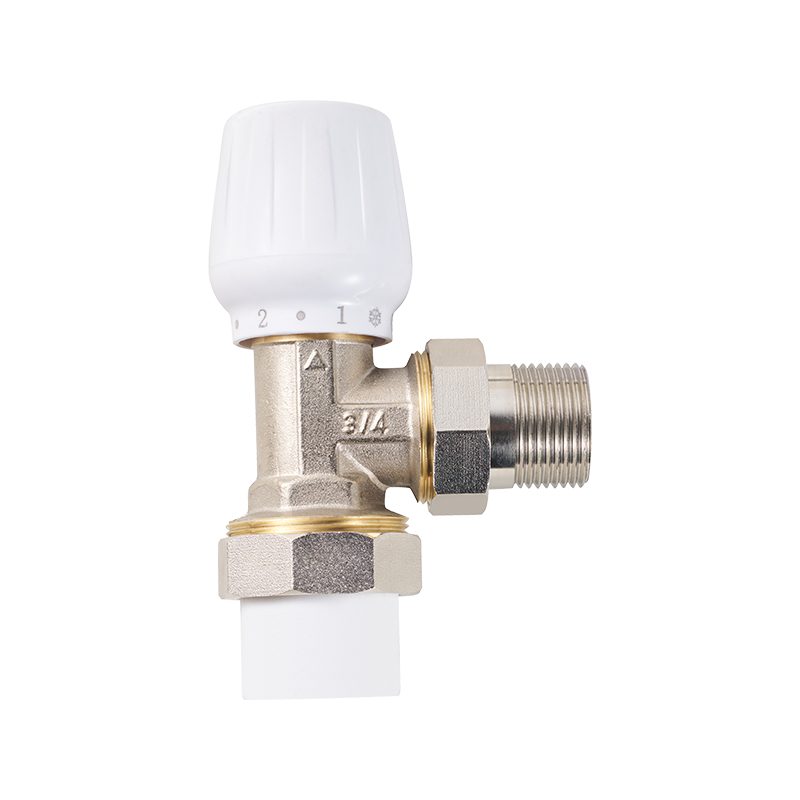

Adjusting building or process systems to account for seasonal changes often requires careful management of both fluid cleanliness and temperature. A Filter Ball Valve paired with a Manual Temperature Valve can help operators respond to seasonal variations efficiently. The Filter Ball Valve ensures that debris does not enter sensitive components, while the Manual Temperature Valve allows for direct control over fluid flow, helping maintain the desired system conditions throughout the year.

Preparing Systems for Seasonal Shifts

Seasonal adjustments often involve changes in temperature requirements or flow conditions. By monitoring the system through a Manual Temperature Valve, operators can regulate the amount of hot or cold fluid circulating in the system. This manual control provides flexibility to accommodate fluctuations in outdoor temperature or process demands without requiring automated systems. Combined with a Filter Ball Valve, the system also remains protected from particles that could affect heat exchangers or other sensitive equipment.

Simplifying Routine Maintenance

Seasonal transitions are an ideal time to inspect valves and filters. Filter Ball Valves are designed with accessible filter elements that can be removed, cleaned, or replaced with minimal effort. This feature allows maintenance personnel to clear debris before it impacts equipment performance. Manual Temperature Valves support these adjustments by enabling operators to check temperature settings and adjust flow to match seasonal needs, ensuring a smoother transition and more consistent system operation.

Adjusting Flow for Comfort and Efficiency

In heating or cooling systems, seasonal changes often require modifications in flow rates. Manual Temperature Valves allow users to make incremental adjustments to fluid flow, affecting the heat transfer and temperature distribution. This capability is particularly helpful in systems where small temperature changes can influence comfort or product quality. Meanwhile, the Filter Ball Valve maintains fluid cleanliness, preventing obstructions that could reduce flow

Enhancing Longevity of Components

Debris in pipelines can cause wear and corrosion over time. A Filter Ball Valve captures particles before they reach sensitive devices, supporting the longevity of pumps, heat exchangers, and other appliances. Regular seasonal inspection of both the filter and temperature settings can reduce wear on system components. By managing flow and maintaining cleaner fluid, operators can maintain system performance with less frequent intervention.

Managing Energy Use Across Seasons

Manual Temperature Valves offer the ability to modulate flow according to current temperature demands. During warmer months, flow through cooling circuits may be increased to maintain target conditions, whereas heating circuits can be adjusted during colder months. These adjustments help avoid unnecessary fluid circulation, contributing to energy efficiency. Filter Ball Valves ensure that the fluid remains free of debris, avoiding additional strain on pumps or heating elements caused by blockages.

Adapting to Diverse Applications

Filter Ball Valves and Manual Temperature Valves can be applied in a variety of systems, from HVAC in residential or commercial buildings to industrial processes requiring temperature control. Their combination allows operators to adjust seasonal settings while keeping fluid systems clean and functioning smoothly. This versatility helps manage differences in seasonal operation without introducing complex equipment or frequent replacements.

Supporting Safe and Manageable Operation

By maintaining clean fluid and allowing controlled adjustments, these valves help operators handle seasonal transitions safely. Manual Temperature Valves provide clear, hands-on control over flow and temperature, and the Filter Ball Valve reduces the risk of debris-related issues. Together, they offer a manageable approach to seasonal system changes, ensuring that equipment remains protected and operational adjustments can be performed efficiently.

Planning Ahead for Seasonal Maintenance

Using seasonal adjustments as an opportunity to inspect and maintain valves can improve overall system management. Operators can remove and clean filters, check for signs of wear, and adjust temperature settings as needed. This proactive approach helps systems respond better to changing conditions, reduces unexpected interruptions, and ensures consistent operation throughout the year.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US