Maintaining clean pipelines is crucial for ensuring that appliances and equipment function without interruptions. Using a Filter Ball Valve alongside a Manual Temperature Valve can play a practical role in preventing debris from reaching sensitive components. While the Filter Ball Valve captures particles within the fluid, the Manual Temperature Valve allows operators to monitor and adjust flow conditions, creating a manageable system for everyday maintenance.

Integrated Filtration for Debris Control

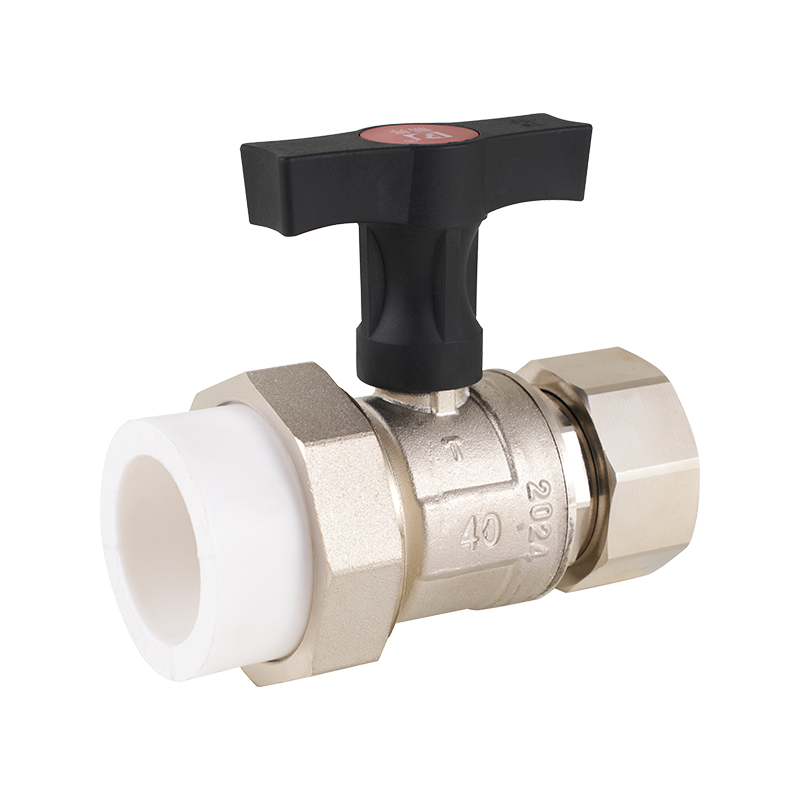

A Filter Ball Valve combines the functions of flow control and filtration in a single unit. The built-in filter element captures debris before it reaches downstream equipment, reducing the chance of blockages or wear. Unlike standard ball valves, these valves provide a straightforward method to control fluid while keeping the system cleaner. By handling debris at the source, operators can maintain appliances with fewer interruptions and reduce the need for frequent repairs.

Accessible Maintenance and Cleaning

One of the practical aspects of a Filter Ball Valve is the ease with which the filter can be removed and cleaned. Routine maintenance can be performed without specialized tools, allowing the valve to return to service quickly. This accessibility helps maintain consistent protection for appliances, as debris is regularly cleared from the system. When paired with a Manual Temperature Valve, operators can check temperature variations during maintenance and make adjustments without shutting down the entire system.

Supporting Consistent Flow

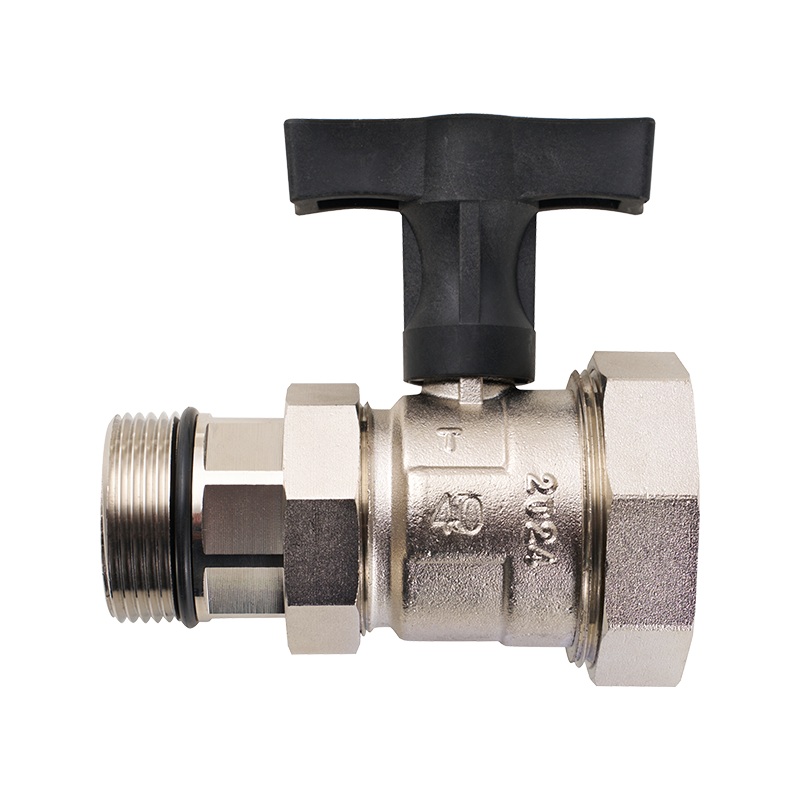

Debris in pipelines can disrupt fluid movement, causing uneven flow or pressure drops that may affect appliances. The Filter Ball Valve helps maintain a steady flow by capturing particles before they enter sensitive equipment. Meanwhile, the Manual Temperature Valve provides a simple method to monitor fluid temperature, which can influence viscosity and flow behavior. Together, these valves allow for a more predictable system environment, reducing the chances of damage caused by inconsistent flow or temperature fluctuations.

Durable Materials for Long-Term Use

Filter Ball Valves are often made from materials such as stainless steel, which withstands wear and contact with different fluids over time. This construction ensures that the valve continues to provide debris filtration without frequent replacements. Manual Temperature Valves are also built to handle regular use and adjustments. Using components designed for durability helps maintain appliance protection without increasing the frequency or complexity of maintenance.

Compact Design for Practical Installations

These valves are designed to occupy space while providing multiple functions. A Filter Ball Valve eliminates the need for separate filters, reducing the number of components in a pipeline. Adding a Manual Temperature Valve allows operators to monitor and adjust conditions without requiring additional room for extra devices. This compact arrangement simplifies installations and makes routine maintenance tasks more straightforward, even in areas with limited space.

Versatile Applications Across Systems

Filter Ball Valves can be applied in various settings, from water systems to industrial processes, wherever debris management is important. They work alongside Manual Temperature Valves to provide a practical approach to controlling both cleanliness and temperature. This combination helps operators adapt to different fluids and operational conditions while maintaining equipment protection and system stability.

Managing Operational Costs

Although a Filter Ball Valve may have a higher initial cost than a standard valve, it reduces the need for separate filters and limits maintenance time, which can lower overall operational costs. Regular cleaning of the integrated filter ensures that appliances remain protected, avoiding unexpected repairs. The Manual Temperature Valve contributes by offering a direct way to monitor and adjust conditions without adding complex systems, supporting efficient day-to-day operation.

Enhancing System Reliability

By capturing debris and allowing temperature adjustments, these valves help maintain consistent conditions for appliances. Operators can monitor and address potential issues before they affect downstream equipment. This proactive approach reduces the risk of damage and ensures that appliances continue to operate under manageable conditions, simplifying the overall maintenance process.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US