Efficient pipeline management often depends on the choice of valves installed within a system. Among various options, the combination of a Filter Ball Valve and a Manual Temperature Valve can significantly influence routine maintenance and operational control. While the Filter Ball Valve helps manage fluid cleanliness, the Manual Temperature Valve allows operators to monitor and adjust flow temperatures directly, making daily maintenance tasks more straightforward.

Streamlined Maintenance Through Integrated Filtration

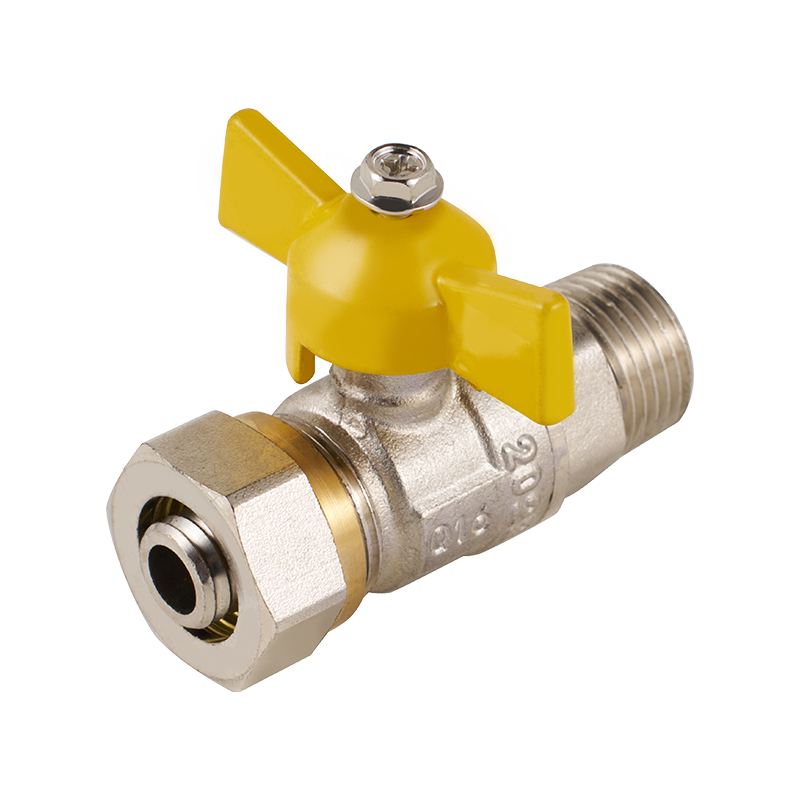

A key feature of the Filter Ball Valve is its built-in filtering element, which captures debris and particles within the fluid. This integration reduces the need for separate filtration devices, simplifying the pipeline layout. By consolidating filtration and control in a single unit, operators can reduce the number of steps required to maintain fluid integrity across the pipeline.

Reducing Downtime With Accessible Components

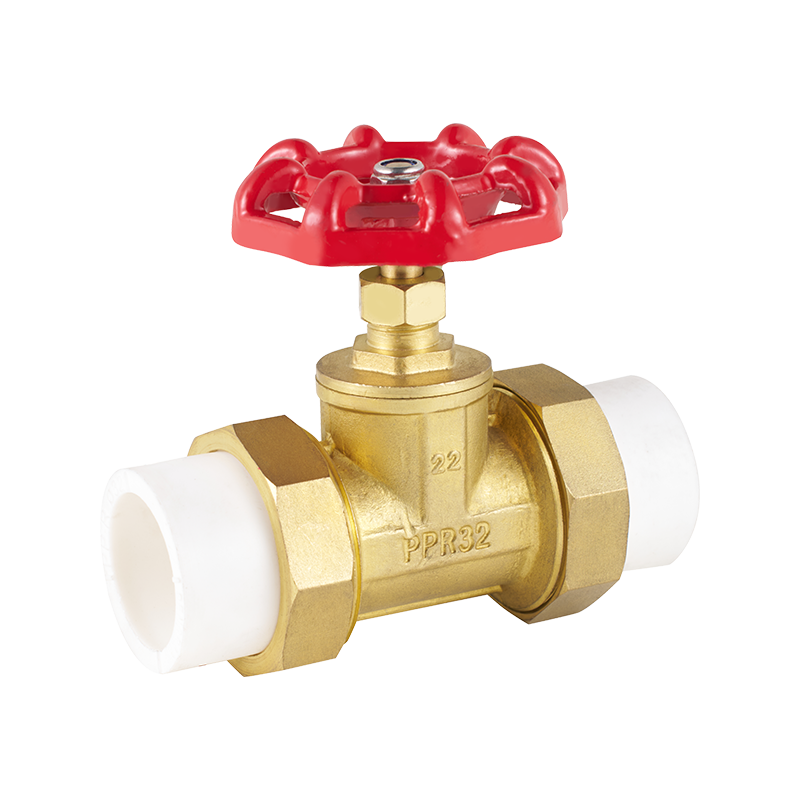

Regular maintenance often involves inspecting and replacing worn or blocked components. Filter Ball Valves are designed so that the internal filter can be removed without specialized tools. This accessibility limits downtime during routine inspections or cleaning, which is particularly useful in facilities where continuous operation is important. Paired with a Manual Temperature Valve, operators can also monitor temperature variations in real time and make adjustments without halting the system, further supporting uninterrupted workflow.

Versatile Operation Across Applications

The adaptability of Filter Ball Valves makes them suitable for various industrial and commercial settings. They can handle fluids ranging from water to certain chemical solutions, depending on the materials used in construction. Manual Temperature Valves complement this flexibility by providing control over fluid temperature, which can affect equipment wear and process stability. Together, these valves support operators in managing multiple aspects of a system through manageable and straightforward adjustments.

Durable Materials and Wear Considerations

Filter Ball Valves are generally made from corrosion-resistant materials such as stainless steel. This construction allows them to function over long periods even under frequent use or in contact with different fluid types. Manual Temperature Valves are similarly designed to withstand regular handling. The durable design of both valves contributes to lower maintenance requirements and reduces the frequency of part replacements, making daily system checks simpler and less labor-intensive.

Maintaining Fluid Flow and Reducing Obstructions

By integrating a filter directly into the valve, Filter Ball Valves help maintain a steady flow rate by preventing accumulation of particles that could block pipes or equipment. The smooth operation of the ball mechanism ensures fluid movement remains consistent. Manual Temperature Valves allow operators to monitor flow conditions affected by temperature changes, enabling timely adjustments that reduce potential interruptions.

Space-Efficient Design for Compact Installations

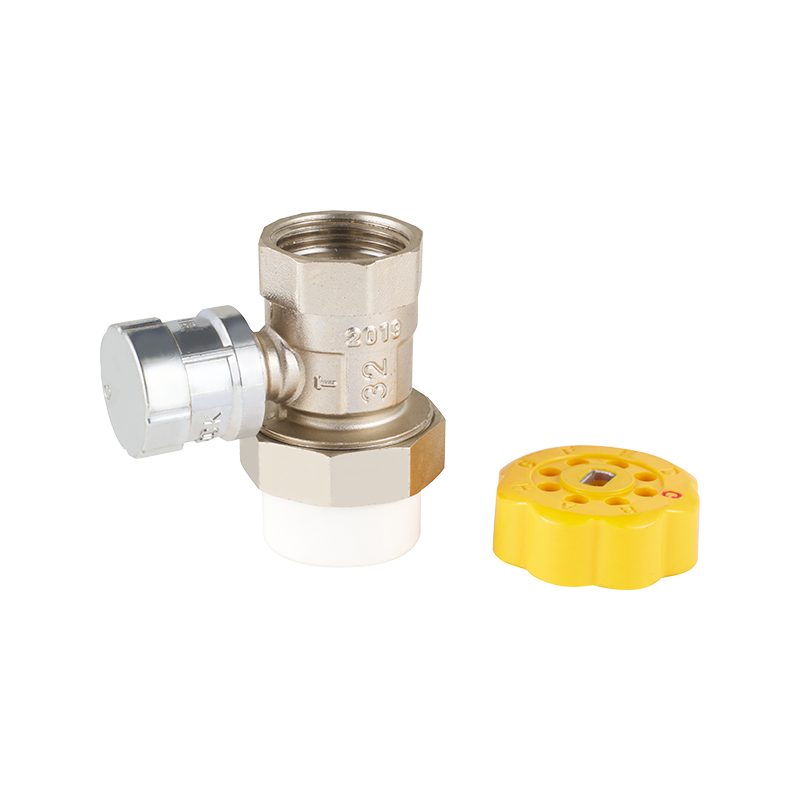

In facilities where pipeline space is limited, combining filtration and flow control in a single Filter Ball Valve is advantageous. The compact design reduces the number of separate components and connections needed. When a Manual Temperature Valve is included, operators can control both temperature and fluid cleanliness without requiring additional space for extra devices. This arrangement simplifies system layouts, making maintenance tasks easier to perform in tight or confined areas.

Cost Considerations and Operational Efficiency

Although integrating a Filter Ball Valve may involve a higher initial investment compared to standard valves, it reduces the need for separate filters and limits maintenance time, which can be more cost-effective over the system’s operating period. Manual Temperature Valves also offer a straightforward way to monitor and adjust conditions without requiring additional equipment or complex monitoring systems. This combination supports routine operational tasks with manageable effort and fewer resources.

Supporting Safety and System Stability

Proper filtration and temperature management contribute to safer and more stable system operation. Filter Ball Valves remove unwanted particles that might damage downstream components, while Manual Temperature Valves help maintain controlled fluid temperatures. For operators, having these two functions accessible within a pipeline makes routine checks more practical, ensuring equipment continues to function as intended without frequent intervention or complex procedures.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US