Managing water distribution across multiple lines requires a combination of fixtures and valves that support flexible flow control and stable operation. A Ball Valve Faucet paired with a PPR Ball Valve often serves this purpose, providing practical solutions for both residential and commercial systems. Understanding why this combination works well for multi-line connections involves examining internal design, material properties, installation flexibility, and maintenance considerations. These factors help system planners and homeowners ensure consistent performance across interconnected pipelines.

Internal Flow Design Supporting Multiple Lines

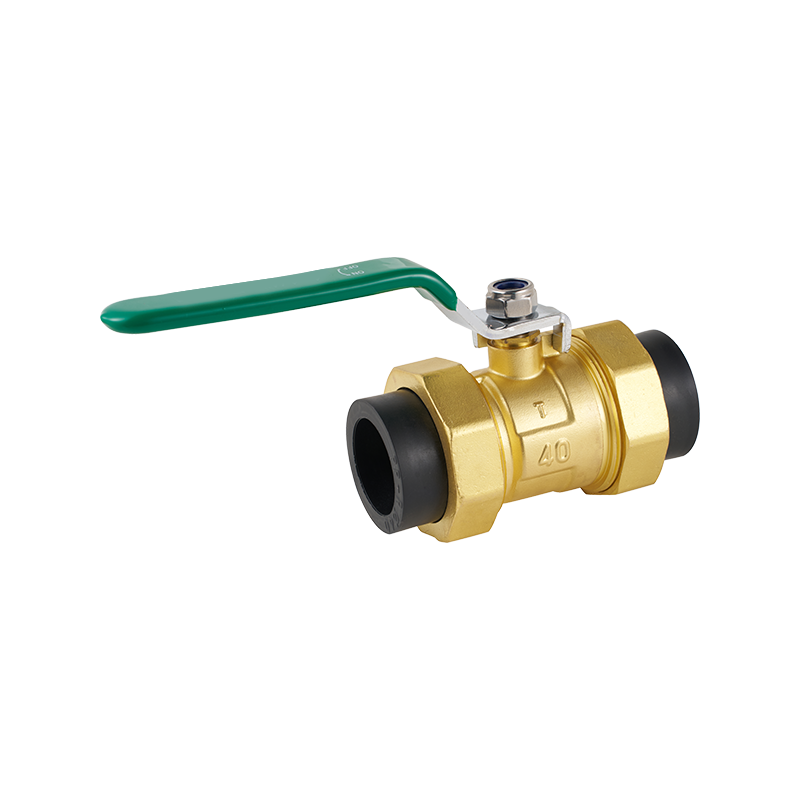

A Ball Valve Faucet features a spherical ball with a drilled passage that allows water to pass through when turned. This design enables straightforward control of water flow, even when multiple lines converge at a single fixture. The quarter-turn operation ensures that the faucet can be opened or closed quickly, making it easier to manage flows from several sources. When installed in a multi-line configuration, the faucet can maintain consistent outlet performance, even if pressure or flow differs among incoming pipes.

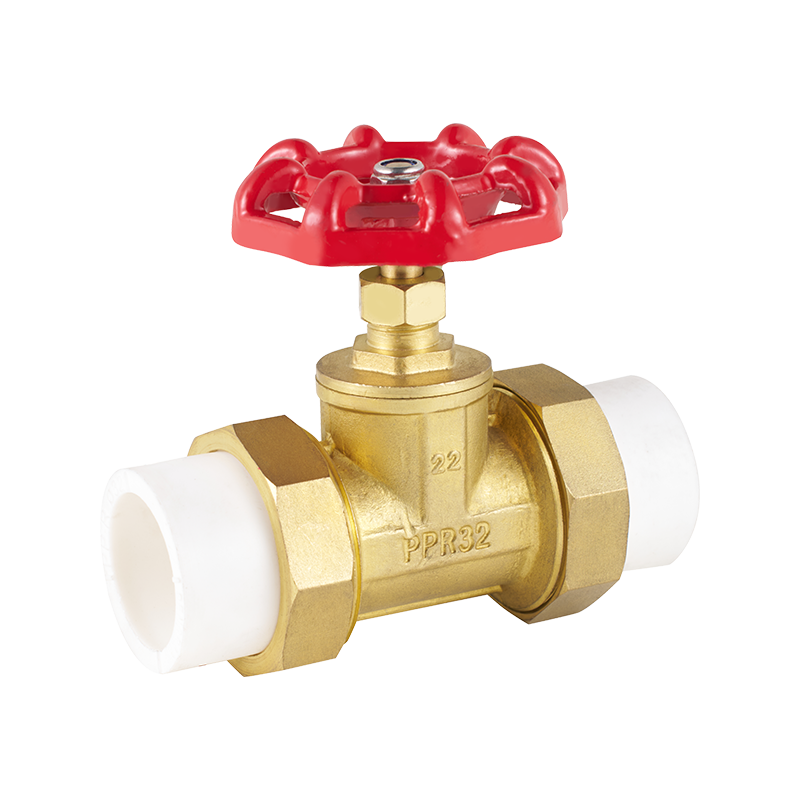

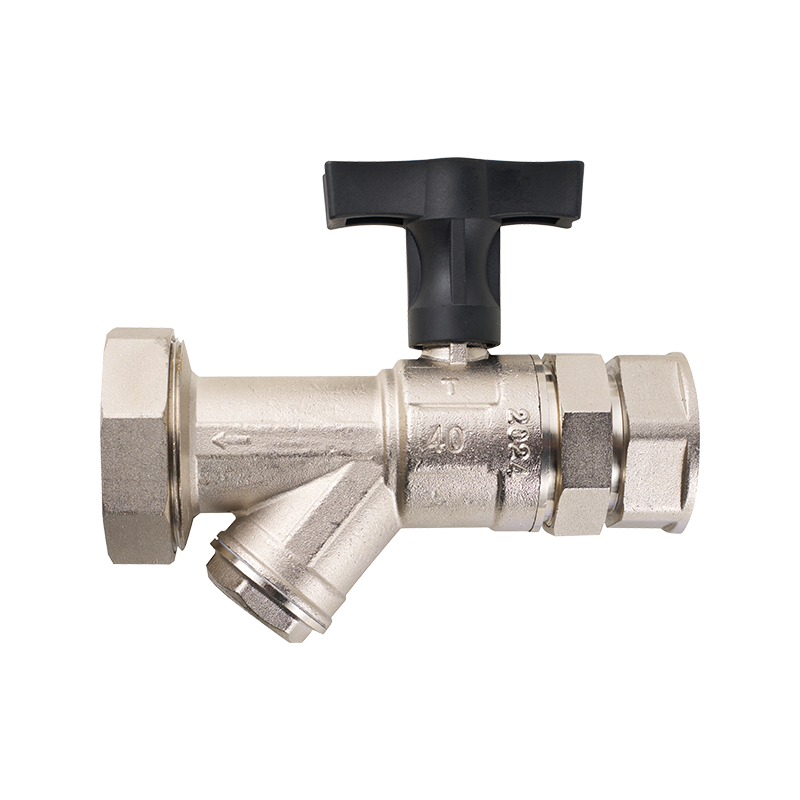

PPR Ball Valves installed upstream complement this arrangement by regulating flow within the main distribution network. Their internal passages are designed to match standard pipe diameters, helping to reduce turbulence at junctions where multiple lines meet. Proper alignment of the ball within the valve body contributes to a smooth transition between the connected lines, supporting more stable flow throughout the system.

Material Properties Supporting Versatile Connections

Polypropylene random copolymer (PPR) material used in upstream valves offers stability under various temperatures and pressures. This characteristic allows PPR Ball Valves to handle flow from multiple branches without compromising the pipeline’s integrity. PPR is resistant to scaling and chemical exposure, which helps maintain consistent internal passages. This becomes particularly important when connecting several lines with different water qualities or temperature levels.

Ball Valve Faucets, often made from corrosion-resistant metals or alloys, provide a user-facing interface that can handle repeated adjustments. The material choice ensures that the faucet remains functional and visually consistent, even when connected to multiple supply lines with varying pressure or usage patterns.

Installation Flexibility for Complex Systems

Multi-line connections often involve branching pipes, risers, and horizontal runs. Ball Valve Faucets can be installed at points where several branches converge, allowing users to control output from a single access point. Ergonomic handles facilitate smooth operation, enabling adjustments without causing abrupt changes in connected lines.

PPR Ball Valves support flexible installation methods, including fusion, mechanical joints, and threaded connections. These valves can be positioned at strategic points along the network, isolating individual branches without affecting other lines. By combining faucet placement with upstream PPR valves, installers can create a controlled network that distributes water efficiently across multiple lines while allowing routine maintenance without major system disruption.

Managing Pressure and Flow Across Multiple Branches

When multiple lines feed a single faucet, differences in pressure and flow can affect performance. The spherical ball design of the faucet moderates these effects by providing a consistent passage for water, preventing sudden surges at the outlet. PPR Ball Valves upstream help balance pressure, ensuring that each branch delivers water smoothly to the converging point.

System planners can observe flow behavior during operation to identify any imbalance. Adjusting the position of valves along individual branches allows minor corrections without needing to shut down the entire system. This is particularly useful in commercial or multi-apartment setups, where uninterrupted access is important.

Maintenance Considerations in Multi-Line Setups

Maintenance is easier when valves and faucets are accessible and designed for regular inspection. Ball Valve Faucets allow straightforward disassembly of the handle and ball assembly if cleaning or part replacement is needed. Similarly, PPR Ball Valves with union connections or accessible installation points allow technicians to isolate sections, inspect seals, or clean internal passages without dismantling extensive piping.

Regular operation of both faucet and PPR valves prevents sticking and maintains consistent flow control. Ensuring that handles are easy to operate and that piping connections remain accessible supports long-term stability in systems with multiple branches.

Practical Use in Residential and Commercial Systems

Multi-line connections are common in buildings with kitchens, utility rooms, and service areas that require flexible water distribution. Ball Valve Faucets installed at usage points provide convenient control, while PPR Ball Valves in the supply network help manage the distribution and isolate sections for maintenance. This combination allows for balanced water delivery across several branches and helps prevent disruption in one line from affecting other lines.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US