Water systems in homes, offices, and commercial facilities sometimes experience sudden fluctuations in pressure, which can affect the performance of fixtures such as a Ball Valve Faucet and a PPR Ball Valve. Understanding how these valves respond to rapid pressure changes helps users manage water flow safely and maintain consistent operation. Both types of valves contribute differently: the faucet serves as the user interface, while the PPR valve regulates flow within the pipeline, and their combined behavior shapes the overall system response.

Internal Design and Flow Regulation

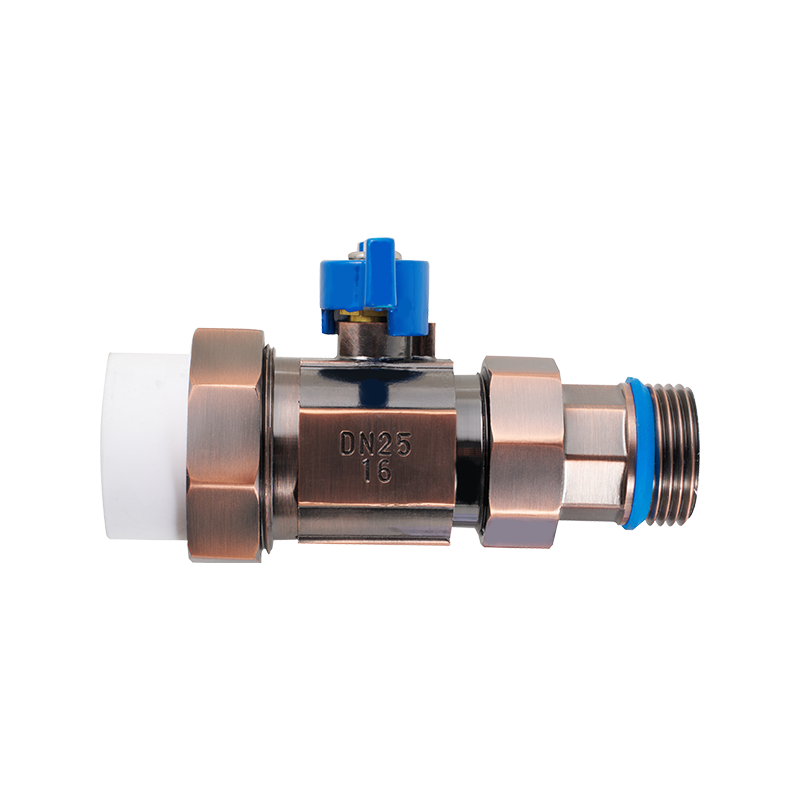

A Ball Valve Faucet relies on a spherical ball with a drilled passage that opens or closes with a quarter turn. This internal structure supports stable flow even when water pressure varies. When a sudden increase in pressure occurs, the faucet’s ball acts as a partial barrier, reducing abrupt changes at the outlet. Smooth operation depends on precise machining and the alignment of the ball with the valve seat. Irregularities or misalignment can cause vibrations, water hammer, or uneven flow, so correct installation and maintenance are important.

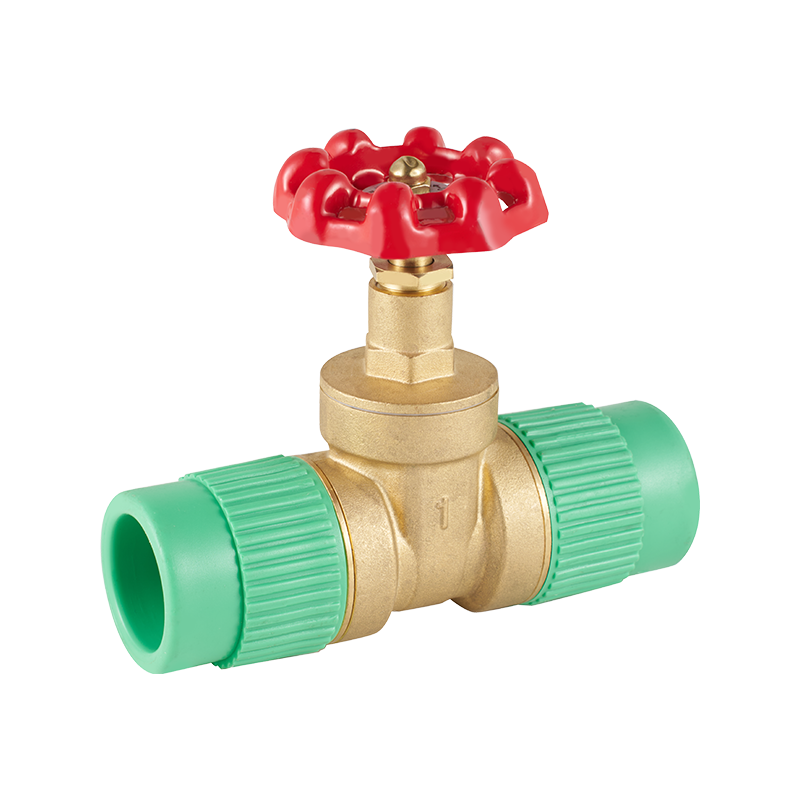

A PPR Ball Valve installed upstream complements this process by controlling flow within the piping network. The valve’s material properties, including resistance to scaling and slight flexibility under pressure, allow it to absorb minor surges. By maintaining a steady internal passage, the PPR valve helps limit the impact of sudden pressure changes on downstream faucets and fixtures.

Effects of Pressure Surges on Faucet Performance

Pressure fluctuations can arise from several sources: closing a nearby valve, starting a pump, or sudden demand changes within the system. A faucet connected to a PPR pipeline can experience a rapid increase in flow velocity, which may cause noise, vibration, or temporary changes in water delivery. The ball valve’s spherical design moderates these effects by providing a consistent flow path that responds gradually rather than abruptly. This is particularly useful in settings where multiple fixtures share a single supply line, as the faucet can accommodate changes without causing spills or splashing.

The faucet handle design also contributes indirectly to handling pressure changes. Ergonomic handles allow precise control during adjustments, letting users open or close the valve smoothly without sudden jolts that could intensify pressure effects. For facilities that operate with frequent on-off cycles, handle accessibility and smooth turning reduce the likelihood of water hammer and maintain predictable flow behavior.

Role of PPR Material in Pressure Adaptation

Polypropylene random copolymer (PPR) used in upstream valves exhibits dimensional stability under varying temperatures and pressures. This characteristic helps pipelines maintain integrity during sudden surges, avoiding deformations that could impact flow. PPR valves can withstand typical commercial and residential pressure variations without cracking or losing their sealing efficiency. In combination with Ball Valve Faucets, the system provides a balanced response that moderates pressure changes from entry points to usage points.

Additionally, PPR’s smooth internal surface reduces friction, which allows water to move more consistently even during transient pressure events. Less turbulence means that downstream fixtures, including faucets, experience fewer abrupt shocks, making the system easier to manage and maintain.

Placement Considerations for Managing Pressure Changes

Where valves are installed significantly influences how well the system handles pressure shifts. Ball Valve Faucets positioned near sinks, utility stations, or work areas serve as the final control point, allowing users to moderate flow immediately. PPR Ball Valves installed upstream, often near junctions, risers, or branch lines, help isolate sections of the system and buffer pressure spikes before they reach fixtures.

Facilities benefit from strategic placement by reducing the risk of vibration, dripping, or noise at frequently used outlets. Accessible positioning also supports routine inspection, allowing valves to be operated occasionally to ensure that seals remain flexible and internal pathways unobstructed.

Maintenance and System Longevity

Regular inspection and maintenance help valves respond predictably to sudden pressure changes. Ball Valve Faucets can require cleaning or lubrication of the handle mechanism and occasional replacement of seals if water quality is variable. PPR Ball Valves, though low-maintenance, benefit from periodic operation to prevent internal components from sticking. Keeping both types of valves in proper condition ensures the system absorbs transient pressure events without creating operational issues.

Understanding how pressure interacts with material properties and valve design allows homeowners, facility managers, and maintenance personnel to address potential problems proactively. Observing flow patterns during normal use and after system changes, such as adding pumps or adjusting branches, provides practical insights into whether the valves are positioned and functioning appropriately.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US