Across many commercial facilities, water systems often use a combination of fixtures such as a Ball Valve Faucet and a PPR Ball Valve to manage flow, support regular operations, and ensure practical control during maintenance. Decision-makers in hotels, workshops, food-service areas, and manufacturing units typically look for valves that handle frequent use and varied working environments. Understanding why PPR Ball Valve options are often chosen helps commercial managers plan installations more effectively and address long-term maintenance needs with greater clarity.

Why Material Behavior Matters in Commercial Settings

Commercial plumbing systems differ from residential ones because they often operate for longer hours and serve multiple users. PPR, known for its stable performance under temperature changes and pressure fluctuations, is frequently selected for pipelines that carry hot and cold water. Its resistance to corrosion from common processing fluids or treated water helps reduce issues that might otherwise interrupt operations.

For facilities that use Ball Valve Faucets at workstations—such as cleaning stations, production benches, or service counters—the pairing with PPR pipelines provides a steady water supply that remains unaffected by prolonged use. Many commercial managers value materials that do not require frequent surface treatment, especially in areas where exposure to steam, detergents, or dust is common. This reduces the frequency of service interruptions and allows staff to operate without needing constant adjustments.

Installation Flexibility and System Layout Requirements

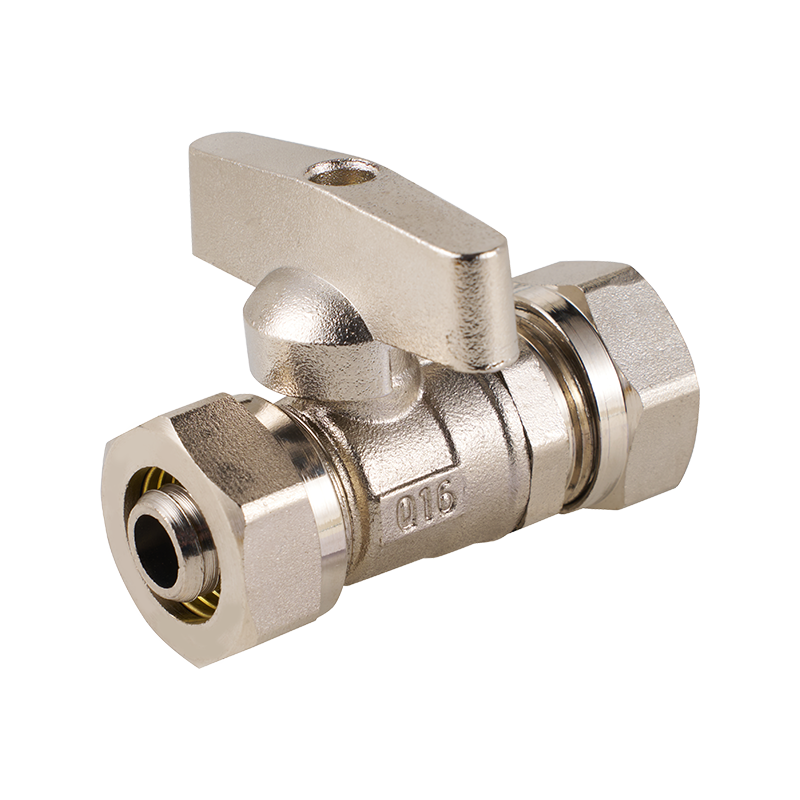

Many commercial environments involve complex layouts with multiple branches, vertical drops, and long-distance water distribution. A PPR Ball Valve offers adaptability to these varied system designs because it is compatible with welded, fusion, and mechanical connection methods. Installers appreciate this flexibility when working in limited spaces such as maintenance shafts, suspended ceilings, or behind equipment lines.

Ball Valve Faucets placed at service points often need easy-to-access shutoff mechanisms. PPR Ball Valves are commonly installed upstream to isolate specific zones without affecting the entire floor or building. This zoning approach helps facilities handle routine adjustments, filter replacements, or fixture swaps during business hours without disrupting unrelated areas.

Commercial kitchens, laundry rooms, and workshops benefit from this structured layout by allowing maintenance teams to work quickly when necessary. When valves are positioned according to the facility’s workflow and equipment placement, staff can manage tasks more efficiently.

Handling Temperature and Pressure Variations in Daily Use

Many facilities use water at different temperatures for cleaning, processing, or sanitation tasks. PPR Ball Valves maintain structural consistency under these varied conditions, which is a key reason they are preferred over certain metal valves that may react to high-temperature water or constant moisture. Their resistance to scaling is also significant in facilities located in hard-water regions, where mineral buildup can gradually affect metal components.

Ball Valve Faucets installed at sink stations or rinse areas support quick on-off control, especially when workers need short bursts of water. When connected to PPR piping, the flow tends to remain stable, reducing sudden pressure fluctuations that can occur when multiple users open valves simultaneously. This predictable flow pattern helps prevent equipment strain and maintains a smoother workflow for staff.

Maintenance Considerations Important to Facility Managers

Scheduled maintenance is a routine part of managing commercial buildings. For this reason, valves that allow straightforward inspection and occasional part replacement are often prioritized. PPR Ball Valves can be serviced without complicated tools, especially when installed with union ends that allow removal without disturbing long sections of piping.

Since commercial facilities aim to reduce downtime during operating hours, the ability to isolate small sections through strategically placed PPR Ball Valves reduces the time technicians spend shutting down large portions of the system. This supports smoother maintenance routines and helps maintain operational continuity.

Ball Valve Faucets also contribute to easier maintenance when used at surface level. Their simple turning mechanism, combined with accessible handles, allows quick flow control during cleaning or part replacement. Facilities with frequent equipment washdowns or sanitation cycles benefit from valves that withstand repeated handling.

Practical Cost and Longevity Considerations

Commercial operators often evaluate long-term performance rather than focusing only on initial installation costs. PPR Ball Valves offer consistent use over extended periods, reducing the frequency of replacements caused by corrosion, scaling, or material fatigue. This becomes particularly useful in environments such as production floors or food-service zones, where equipment and fixtures operate continuously.

English

English русский

русский Español

Español عربى

عربى

CONTACT US

CONTACT US