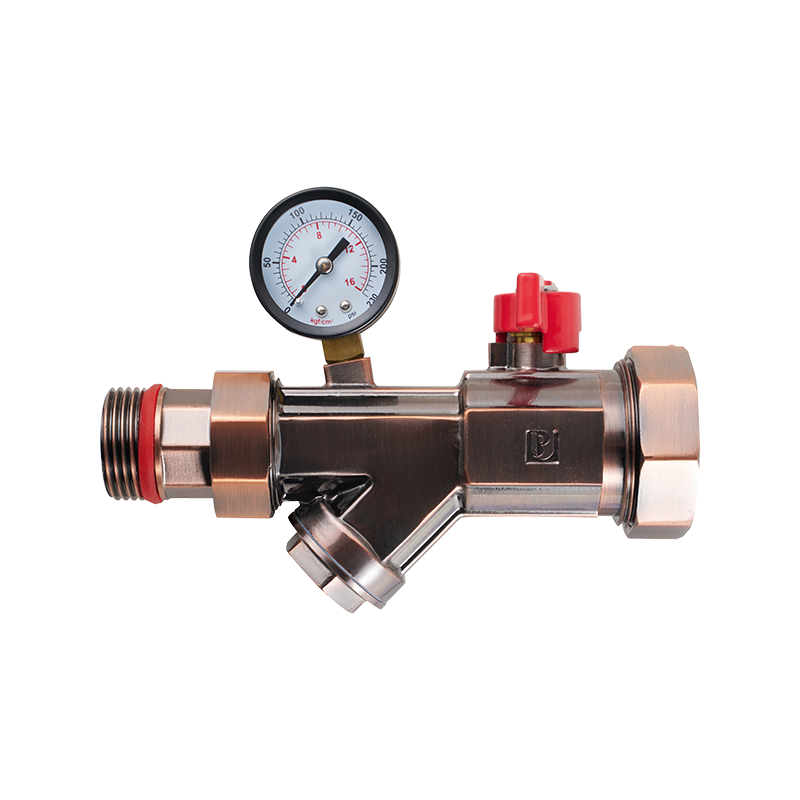

Adjusting building or process systems to account for seasonal changes often requires careful management of both fluid cleanliness and temperature. A Filter Ball...

Product Search

Exit Menu

- Valve (103)

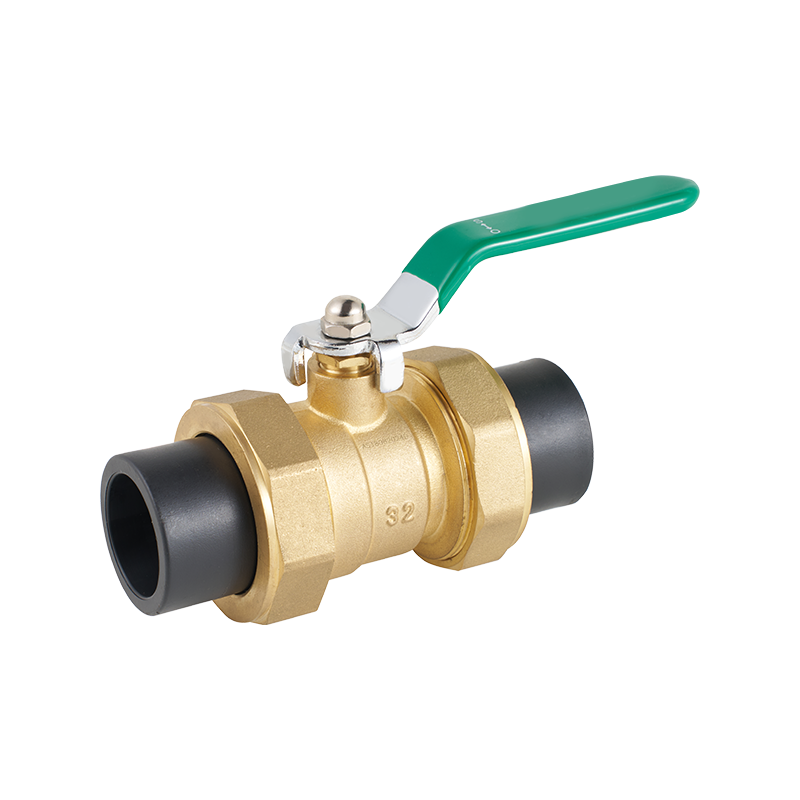

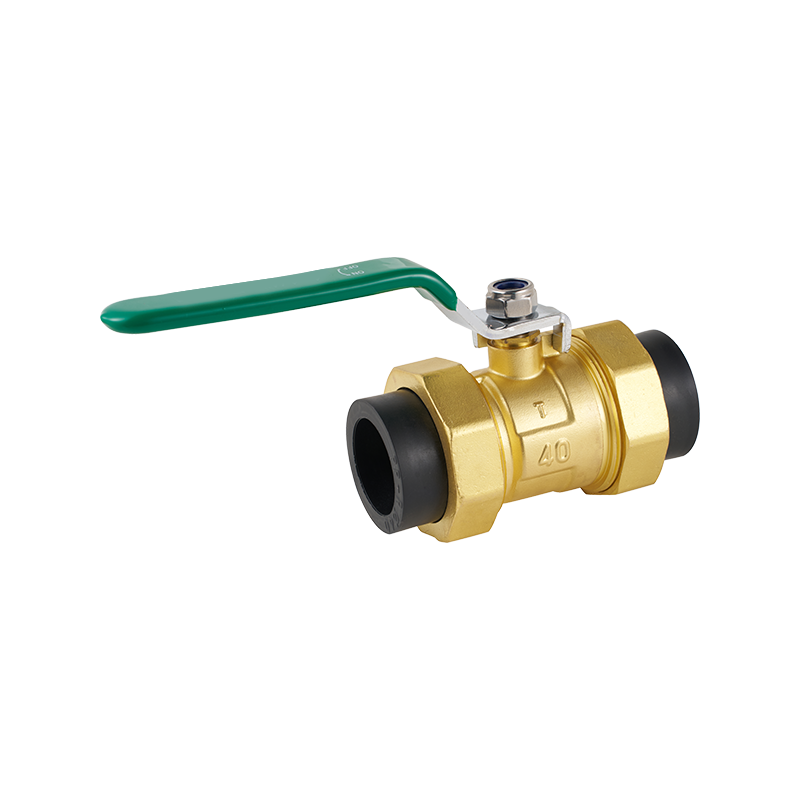

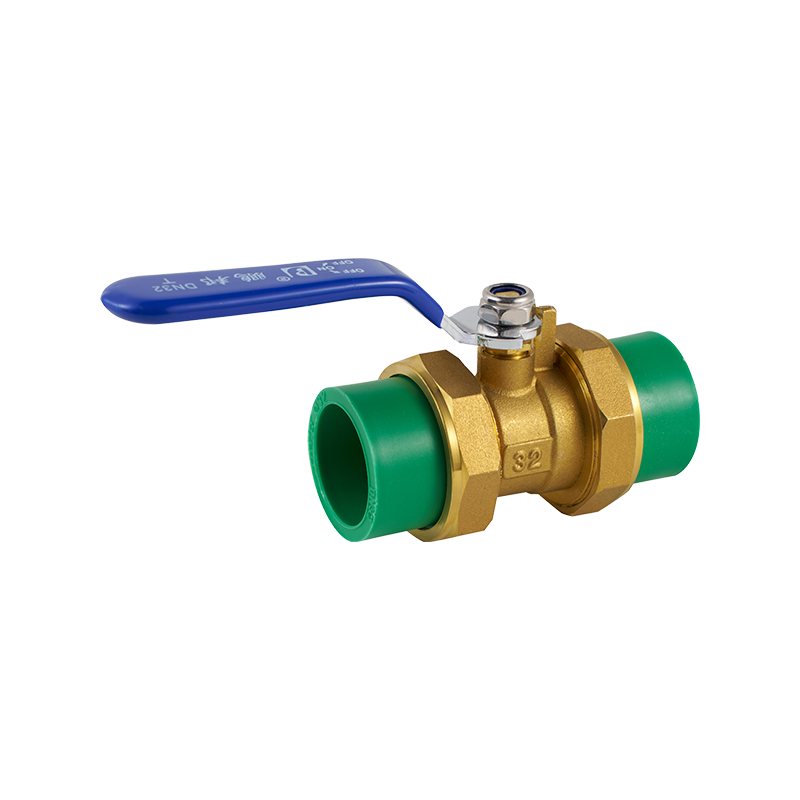

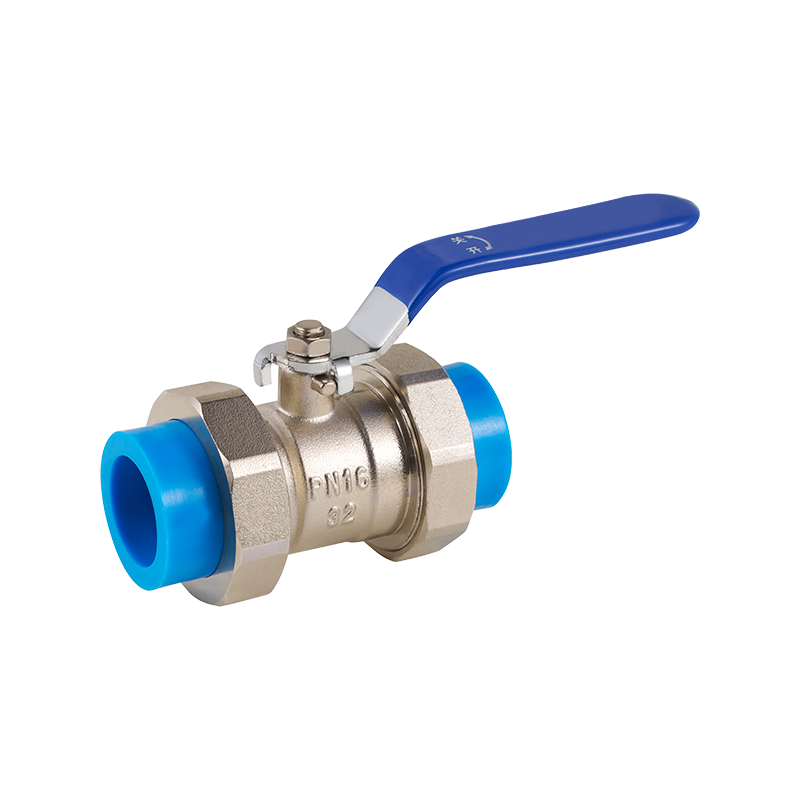

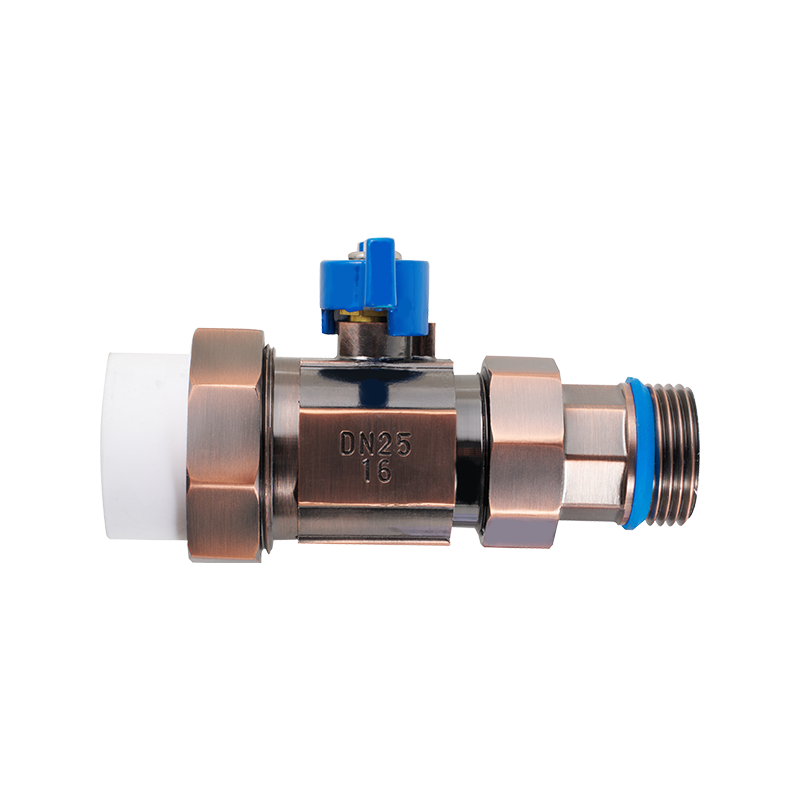

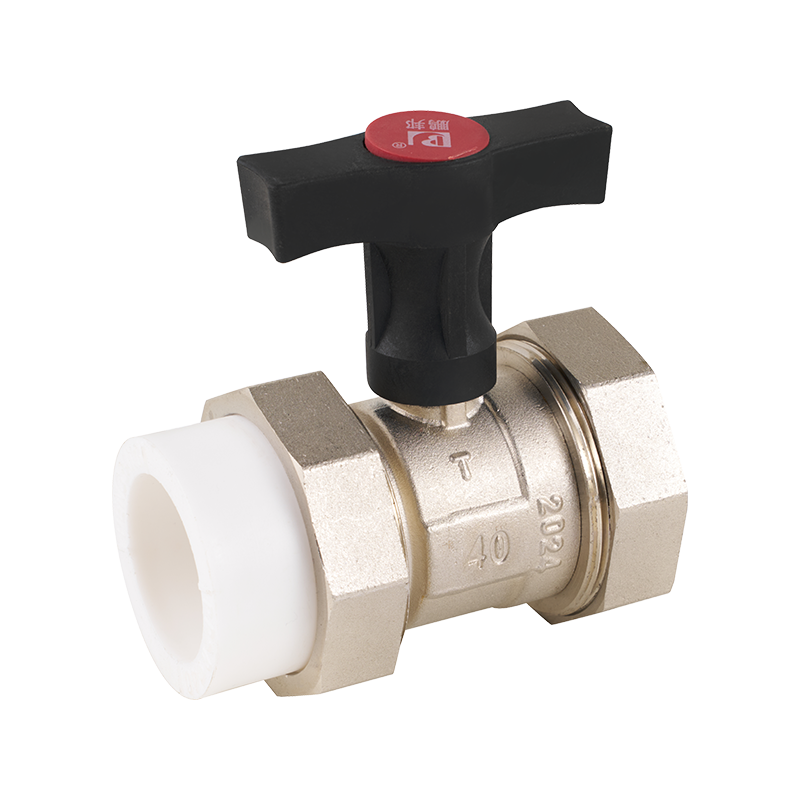

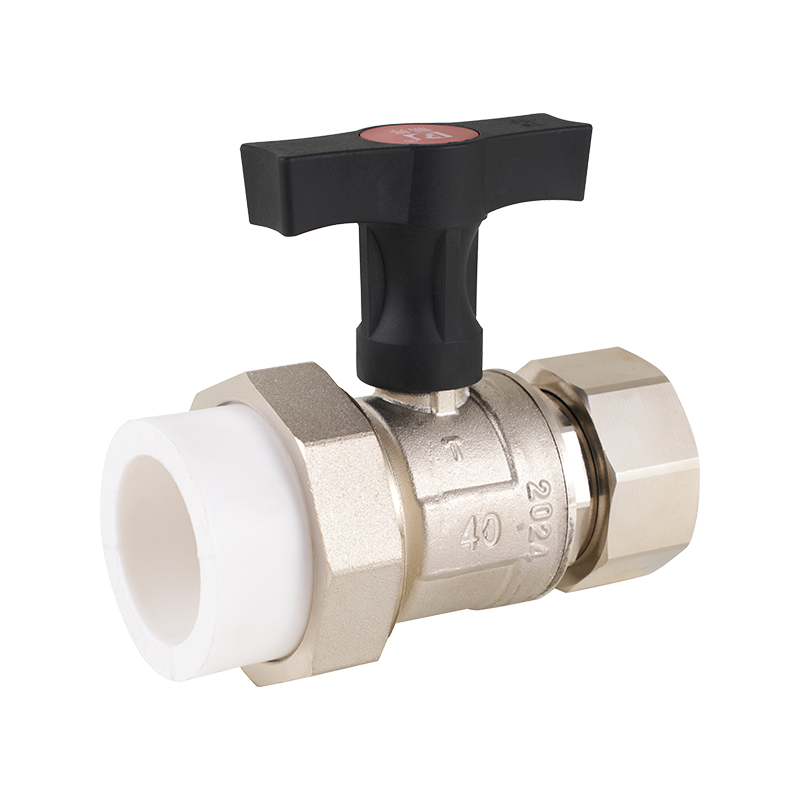

- - PP-R Ball Valve (7)

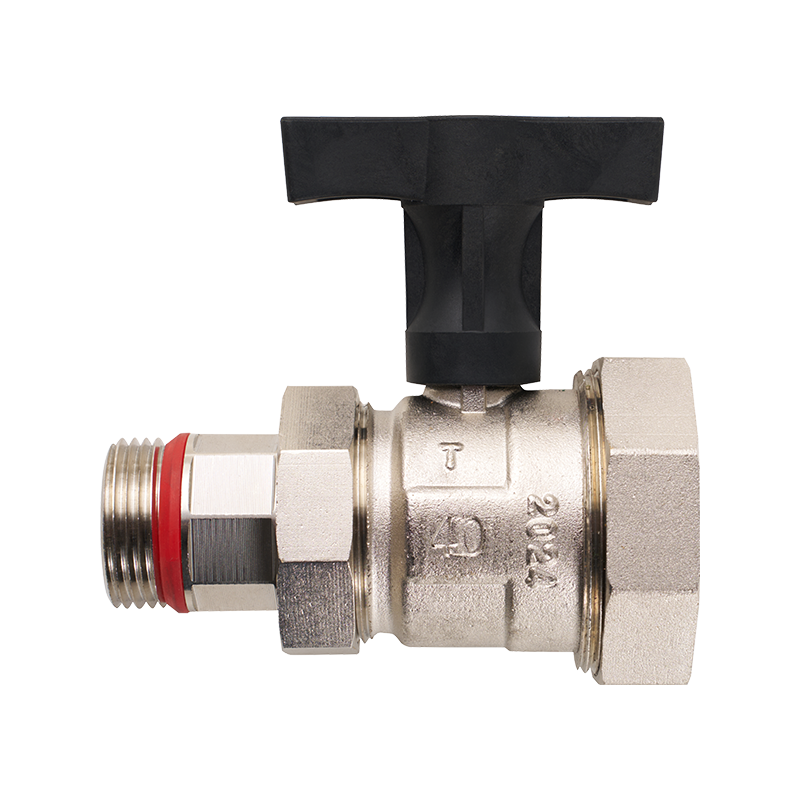

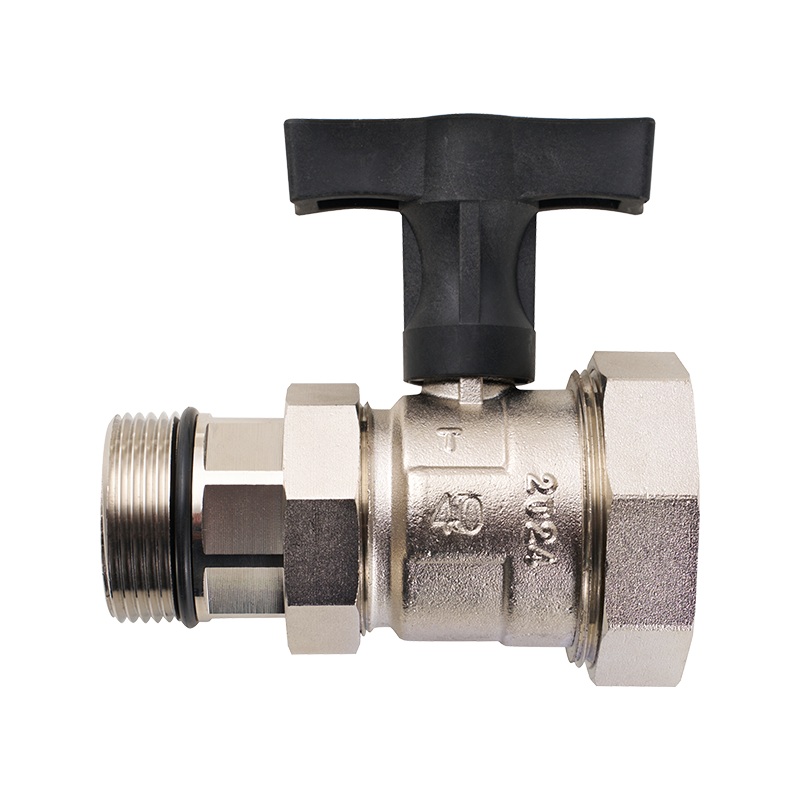

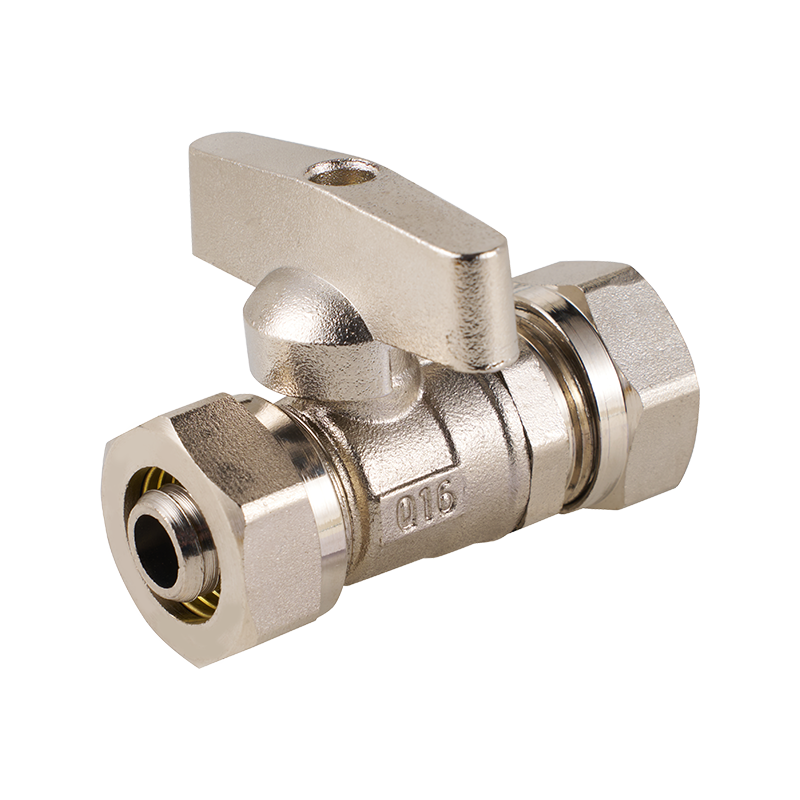

- - Ball Valve (21)

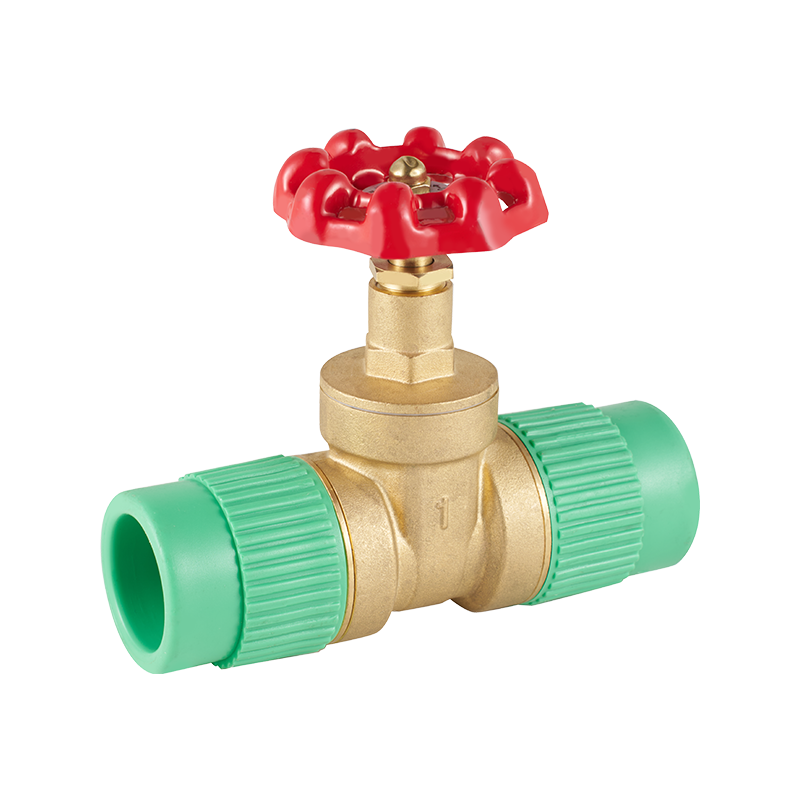

- - Gate Valve (4)

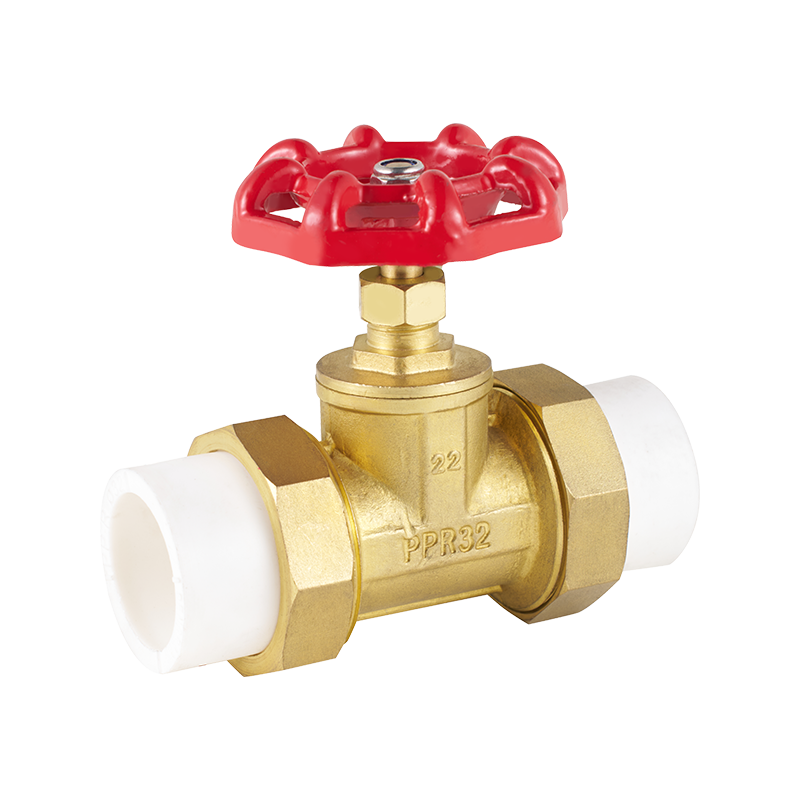

- - Stop Valve (6)

- - Lock Valve (6)

- - Ball Valve Faucet (22)

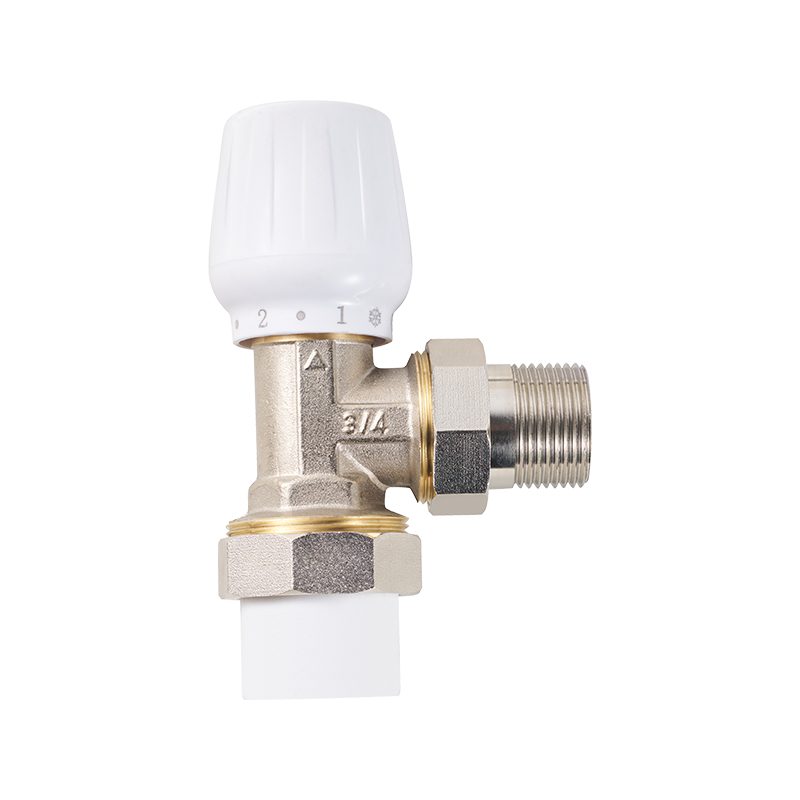

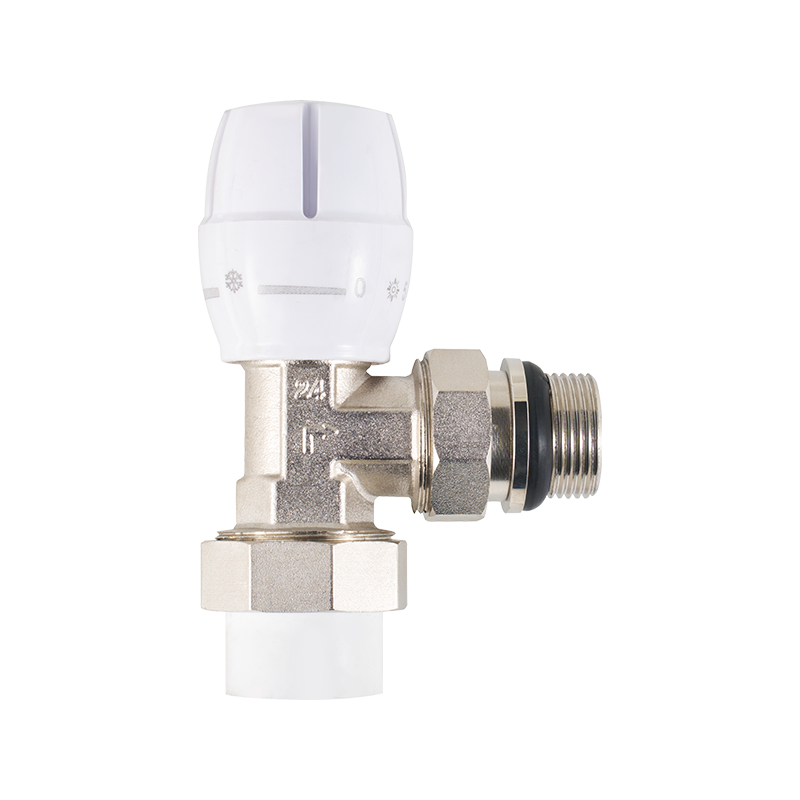

- - Manual Temperature Control Valve (9)

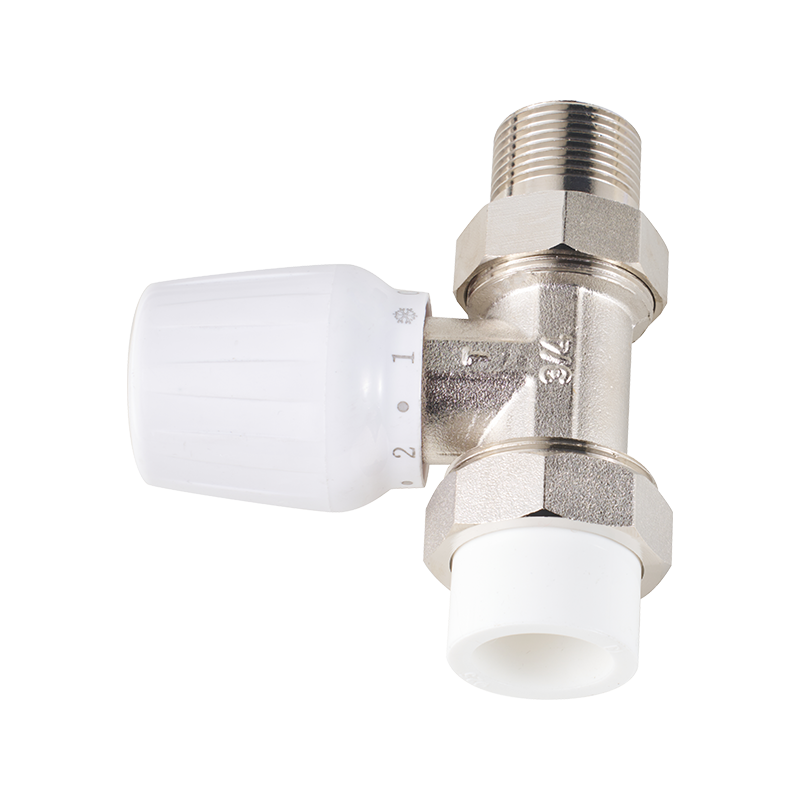

- - Thermostatic Control Valve (9)

- - Filter Ball Valve (6)

- - Check Valve (7)

- - Pressure Reducing Valve (2)

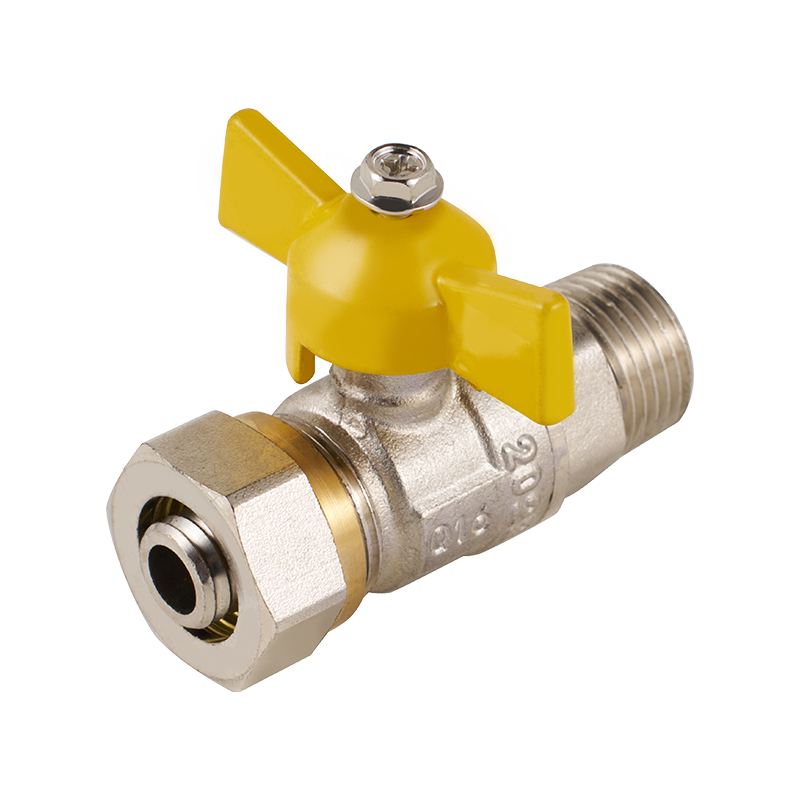

- - Gas Valve (4)

- - Special Valve for Wall-mounted Boiler (0)

- Manifold (3)

- Pipe Fittings & Joint (33)

Product Categories

Innovation Adds Value to Our Products and Your Projects

Contact UsOEM Valve With Handle

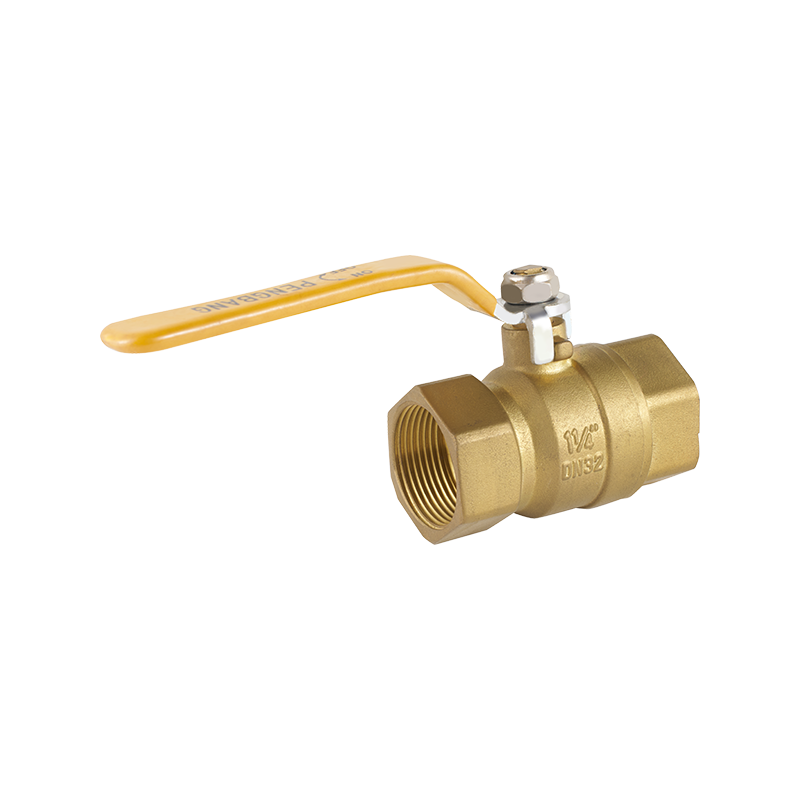

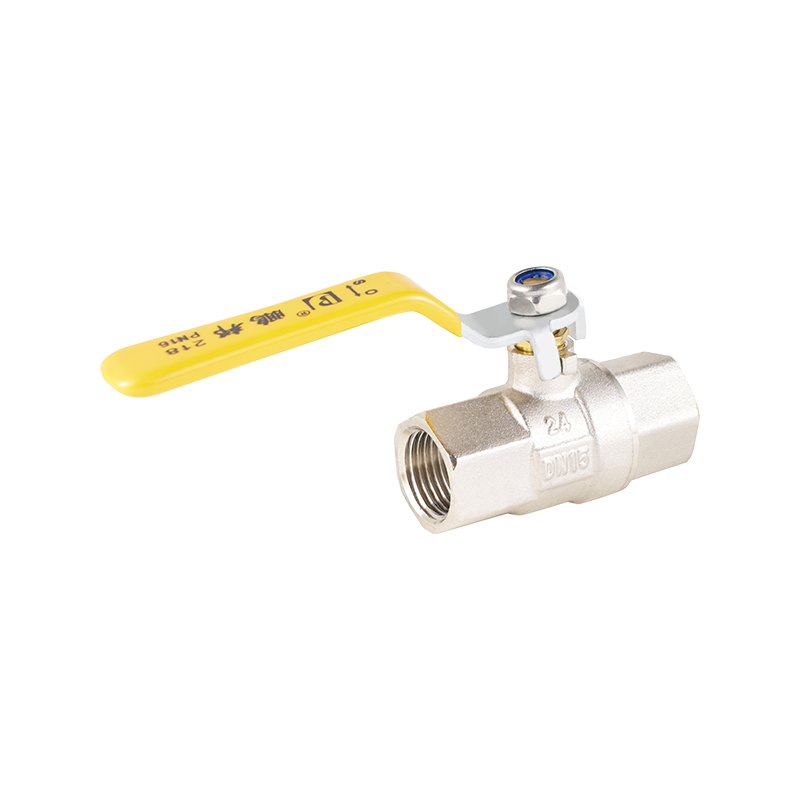

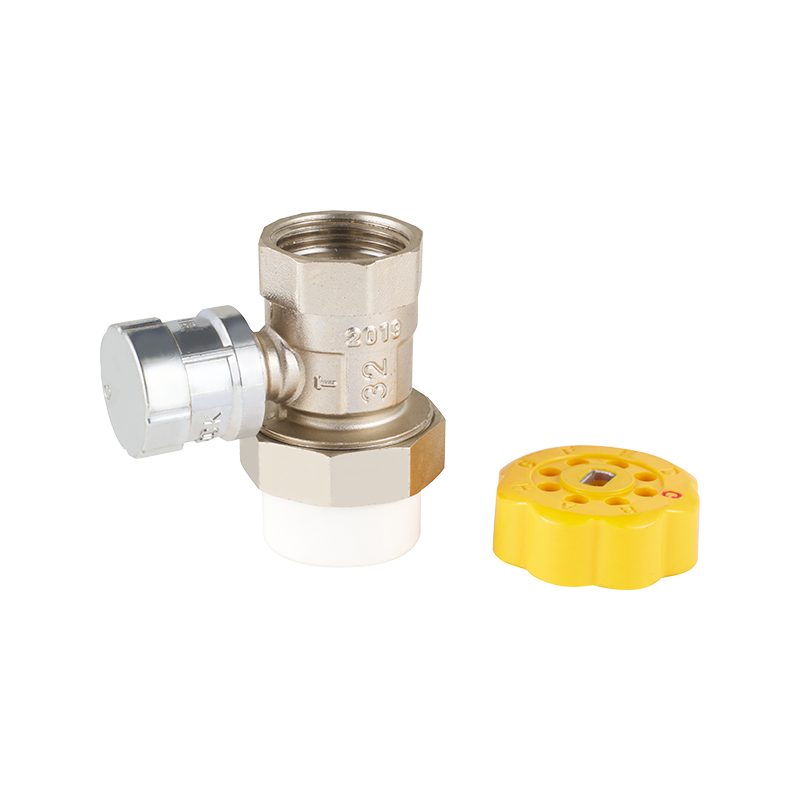

Valves are integral components in fluid control systems, used extensively in industries such as water and wastewater management, oil and gas, chemical processing, and HVAC systems. There are many types of valves, including PP-R Ball Valve, Ball Valve, Gate Valve, Stop Valve, Lock Valve, Manual Temperature Control Valve, Thermostatic Control Valve, Filter Ball Valve, Regulating Check Valve, Pressure Reducing Valve, Gas Valve, Special Valve for Wall-mounted Boiler, etc.

1. Precision Control:

Valves offer precise control over the flow of fluids. This ability to modulate the flow rate is critical in applications where maintaining a specific pressure or flow is essential. For instance, in chemical processes, precise control of ingredients can prevent reactions from becoming too vigorous or uncontrolled.

2. Durability and Longevity:

Valves are designed to withstand harsh conditions and corrosive environments, which means they have a long service life. High-quality valves, especially those made from materials like stainless steel or other alloys, can operate efficiently for many years without significant wear and tear.

3. Variety of Materials:

Valves are available in a wide range of materials to suit different applications. From brass and bronze for general-purpose applications to stainless steel and exotic alloys for corrosive environments, valves can be tailored to resist corrosion and maintain integrity in a variety of conditions.

4. Versatility in Operation:

Valves come in various types, each with its unique operational mechanism. Ball valves, gate valves, and globe valves, among others, are designed for different flow characteristics and pressures. This versatility allows engineers to select the appropriate valve for each specific application.

5. Ease of Maintenance:

Many valves are designed for easy maintenance. Some models can be repaired or have parts replaced without the need for complete removal, reducing downtime and maintenance costs.

6. Automation Capabilities:

Modern valves can be automated, allowing for remote operation and integration with control systems. This feature is particularly advantageous in hazardous environments or where manual operation is impractical.

7. Safety Features:

Valves often include safety features such as pressure relief mechanisms that can prevent system damage due to over-pressurization. They can also be equipped with fail-safe positions that close automatically in case of a power failure or other emergency.

8. Noise Reduction:

In many fluid systems, such as those found in residential buildings, valves help reduce noise by dampening the flow of water, which can be particularly beneficial in creating quiet and comfortable environments.

9. Energy Efficiency:

Valves contribute to the energy efficiency of systems by preventing unnecessary pressure drops and leaks. By controlling the flow precisely, valves can help reduce the energy required to pump fluids through a system.

10. Environmental Compliance:

Valves play a crucial role in ensuring that fluid systems comply with environmental regulations. They can be used to control the release of chemicals, manage wastewater treatment processes, and ensure that emissions meet legal standards.

11. Cost-Effectiveness:

While initial costs may vary, the long-term savings from reduced maintenance, energy efficiency, and increased safety often make valves a cost-effective investment.

12. Customizability:

Valves can be customized to meet specific requirements, including size, pressure rating, and material specifications. This flexibility allows for the creation of valves that are tailored to the unique needs of each application.

In conclusion, valves offer a multitude of advantages that make them indispensable in various applications. Their ability to control flow, withstand harsh conditions, and ensure safety makes them a crucial component in any fluid management system. Whether it's for industrial process control, residential plumbing, or environmental protection, valves stand out for their versatility and reliability.

As a China Valve suppliers and Valve factory, we are mainly engaged in wholesale Valve, With advanced production equipment, strong technical force, outstanding quality, perfect after-sales service, and a good reputation, Pengbang has been rated as the promotion and application product by China's construction and decorative industry and won the top ten brands of China's valve manufacturing industry. The products sell in more than 50 countries and regions. such as the United States, France, Germany, Italy, Spain, and Australia, and are highly praised by many customers at home and abroad for "integrity, pragmatism, persistence, innovation" management concept; "excellence, continuous improvement, customer satisfaction quality policy; "people-oriented, unlimited service" business purpose is pengbang people's unswerving belief.

-

-

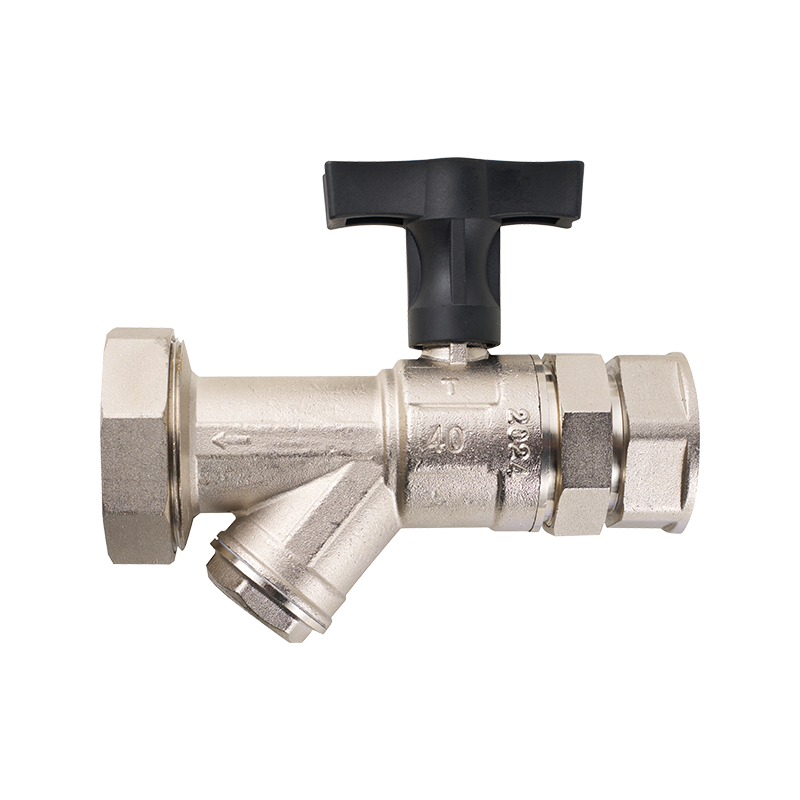

Maintaining clean pipelines is crucial for ensuring that appliances and equipment function without interruptions. Using a Filter Ball Valve alongside a Manual T...

-

Efficient pipeline management often depends on the choice of valves installed within a system. Among various options, the combination of a Filter Ball Valve and...

-

Managing water distribution across multiple lines requires a combination of fixtures and valves that support flexible flow control and stable operation. A Ball ...

- Address : Zhongjia Industry Zone, Fengjiang, LuQiao, TaiZhou city, Zhejiang Province

- Tel : +86-0576-82689868

- Email : Pengbang@pbvalvefitting.com

CONTACT US

CONTACT US

English

English русский

русский Español

Español عربى

عربى